Adjusting 45

°

and 90

°

Stops

The stops have been adjusted at the factory and

should not need any adjustment. If you need to

adjust the stops:

90

°

Stop

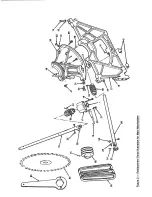

1. Disconnect saw from power source.

2.

Raise the saw blade to its maximum height

by turning the blade raising handwheel

clockwise as far as it will go. Place a square

on the table and turn the blade tilt

handwheel until the blade comes into 90

degrees with the square. Make sure the

square is between the blade teeth.

3. Loosen the jam nut and turn the screw until

it hits the stop (A, Figure 11).

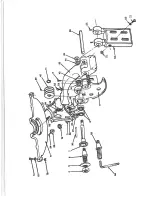

4. If necessary, loosen the screw (B, Figure

13) and adjust the pointer to zero on the

back-up angle scale.

45

°

Stop

1.

Using a 45 guage as shown in figure 12, tilt

the blade until it makes contact with the

guage making sure the guage does not hit

the saw teeth.

2.

Loosen the jam nut and adjust the bolt (A,

Figure 13) until it hits the stop which is

similar to the stop in figure 11 but at the

other end of the rack swing.

3.

Adjust the pointer if necessary.

Figure 11

Figure 12

Figure 13

10