Construction Manual

www.oldschoolmodels.com

Page 5

n n

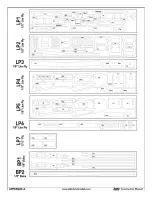

Step 13 - Wing Assembly (SPACER)

Locate SPACERs from LP1. These

are just as the name implies -

simply spacers and should NOT

be glued into the airframe at any

point.

Notice that the pre-cut rectangular

spars holes in R3, both R2’s and R1

are wider than the spars that are in

them. This is to allow for the dihedral braces that will be attached

later on. But you need to make sure the spacing is correct when

gluing the spars in place, hence the use of the SPACERs.

Use one SPACER piece as a substitute for the front dihedral brace

first, by sliding it into the holes on the R1, R2 and R3 ribs. This

should push the spar towards the rear of the pre-cut slots. Then

do the same with the other SPACER for the rear spar holes - again

pushing the spar towards the rear of the cutouts in each rib.

n n

Step 14 - Wing Assembly (R3)

With the SPACERs in place, carefully align rib R3 and the outermost

R2 rib, then tack them in place to the spars (best to tack glue on the

back side of the spars). Make sure that the SPACERS are not glued

to spars or any of the ribs as they will be VERY hard to remove.

n n

Step 15 - Wing Assembly (WH3)

Locate one of the WH3s from LP1.

It’s outer tabs fit into the pre-cut

slots on the back of the R2 ribs as

shown here. Glue it to the outer

R2 rib first, then properly align the

inner R2 rib. Once aligned, glue

that R2 rib in place by tacking it in

place to the back of the spars, and

then glue the WH3 to it as well.

n n

Step 16 - Wing Assembly (WH1, WH2, WH4)

Locate WH1, WH2, and WH4 from LP1. Note that

WH1, WH2 and WH4 have a small circle engraved

on one side. This designates the side that should

face R1 because it has a small angle pre-cut into

it. Glue each WH1, WH2 and WH4

to R2 making sure their tabs are

completely inserted into the holes

on the innermost R2 rib.

n n

Step 17 - Wing Assembly (R1)

Locate DH-JIG from LP1. This is used to help

align R1 in this step. WH1, WH2, and WH3

already have this angle cut into them, but

you can also use this DH-JIG to further aid

the R1 alignment. Slide each of the tabs from

those WH pieces into the pre-cut holes of R1,

making sure they are completely inserted. When properly aligned

you should be able to double-check it with the DH-JIG.

After everything is aligned, tack glue R1 to the back of the spars,

then also glue R1 to WH1, WH2 and WH3.

n n

Step 18 - Wing Assembly (SPACER)

With the ribs all in place, carefully remove the SPACER pieces and

then glue ribs R3, R2 and R1 to the spars. Make sure you do NOT

have any extra glue fouling the holes where the dihedral braces

will slide into.

n n

Step 19 - Wing Assembly (R1A)

Locate two of the R1A pieces from

LP1. These are glued into the center

rectangular cutout in WH4 and WH3 as

shown here, pointing towards the trailing

edge of the wing. Make sure they are

firmly seated as the glue cures.

n n

Step 20 - Wing Assembly (trailing edge)

Locate one 1/4” square length of balsa

strip. This will be the trailing edge of

the wing. Measure and trim it to length,

leaving about an extra 1/4” or so. Then

carefully slide it on to the back of each

of the ribs and it should be held in place

between the two “fingers/fangs/points”

on the back of each rib. Working from one side to the other, glue

the trailing edge to each of the ribs, making sure that the alignment

of each rib is still spot on.

n n

Step 21 - Wing Assembly (leading edge)

Locate one length of 1/2” square

balsa strip. This is the leading edge

of the wing. Measure and trim it to

length, again, leaving about a 1/4”

extra. Working from one end to

the other, glue the leading edge in

place to each of the ribs, making

sure it is firmly seated into the pre-cut, angled slot of each rib.

n n

Step 22 - Wing Assembly (trailing edge sanding)

You'll now need to very lightly sand the

trailing edge. Refer to this diagram to

show what I'm on about. The trailing

edge needs just a little sanded off the

rear edge it so it will continue the airfoil

shape. Do this for the top and bottom

surface of the trailing edge.

n n

Step 23 - Wing Assembly (CS1, CS5)

Locate one CS1 from BP15 and one CS5

from LP7. CS5 fits into the pre-cut notch

of CS1 as shown here. Before gluing

it place, lightly sand the edges of CS5

where it will contact CS1, so you’ll have

a good fit. When happy with the fit, carefully apply glue to the

two contacting edges of CS5 and attach it to CS1. Apply a bit of

downward pressure along the seams to make sure the joint is flat

along the edges as the glue cures.

n n

Step 24 - Wing Assembly (CS1, CS2, CS3)

Take CS1 from the previous step, and locate one CS2 from BP15

and one CS3 from BP16. After trimming, these will all be glued

together to form the top sheeting of the wing’s center section.

Place the CS1 assembly in place on the rear section of the wing,

then place the CS2 on the front edge, simulating how it will wrap

around the leading edge rib curve (temporarily tape in place if that

Sand this lip to

match airfoil