Construction Manual

www.oldschoolmodels.com

Page 9

British

Sunday Fighter

Bristol Spadport

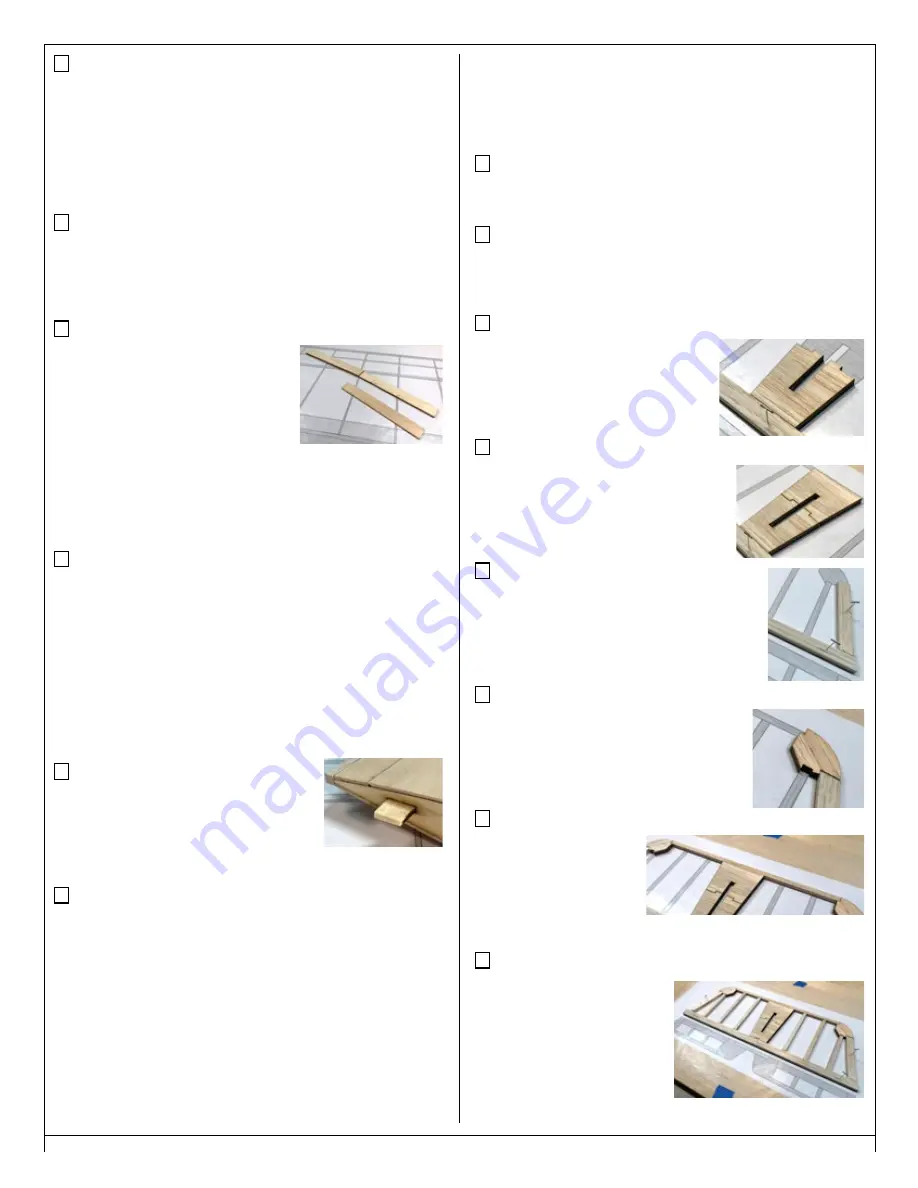

Step 45 - Bottom Wing Assembly (R2 cutout)

Just as you did for the top wing halves, it’s time to mark and

cutout the slots in R2 to accept the dihedral braces. These are be

rectangles and is positioned between the upper and lower spars,

as well as the front and rear sheer webs.

Use a rotary tool for the main portion, then a sharp hobby knife

for the corners. Take care not to damage the balsa sheer webs or

weaken the spars.

Step 46 - Wing Assembly (sanding)

Sand the tip and root ribs of all four wing halves to remove any

extra spar and sheeting material. Make sure they have smooth,

flat surfaces. Attach TR1 and TIP to the tip ribs, as you did on the

upper wing.

Step 47 - Wing Assembly (DH1/DH2)

Locate two DH1’s from LP1 and four

DH2’s from BP9. These pieces are

laminated together with a thin layer

of epoxy to form two identical wing

dihedral braces.

Two DH2’s are glued to each side of each

DH1 to form thicker pieces.

Note that there is an etched circle in each DH2 that designates the

angled cut. Align these properly so it matches the angle of DH1.

To insure the pieces stay perfectly aligned, clamp or weigh down

both assemblies until the glue fully cures.

Step 48 - Wing Assembly (join wing halves)

Now take one of the assembled dihedral braces and test fit into

the wing slots of the top wing halves. You will probably have to do

a bit of sanding on the brace to allow it to easily fit into each slot.

Don’t take off too much, too fast. Carefully sand as necessary to

make sure everything fits properly and the root ribs in each wing

half are touching along their entire length when assembled into a

single wing. Take your time and get a good fit that doesn’t require

a lot of force.

Once you’re happy with the top wing’s fit, do the same with the

bottom wing halves and the remaining dihedral brace assembly.

Step 49 - Wing Assembly (PIN)

Locate both PIN’s from LP3. These are anti-

rotation pins and are used to help align the

rear portion of the wings.

Glue one PIN halfway in the upper port wing

half and the other halfway in the lower port wing half.

Step 50 - Wing Assembly (join wing halves)

Test fit the wing halves together one last time and sand as necessary

for a good fit.

After test fitting, join the top wing halves permanently with a bit

more 30 minute epoxy. Remove the dihedral brace and apply the

epoxy into the pockets in each wing half and also coat the faces of

each root rib.

Slide all the dihedral brace into one of the wing halves, then slide

remaining wing half in place. Using a couple of clamps (or tape),

hold wing halves firmly together. Wipe off any excess epoxy and

remove the clamps only after the epoxy has fully cured.

Remember, any twist in the alignment of the panels cannot be

fixed after the epoxy cures and will lead to a poor flying model.

Set the top wing aside and then do the same to assemble the

lower wing.

This completes assembly of the Sunday Fighter wings.

Now it’s time to start construction of the tail surfaces.

Prepare your work area

Now tape the elevator/stab plan and a fresh piece of waxed paper

on your building board.

Step 51 - Horizontal Stab Assembly (trailing edge)

Locate the 1/4” x 1/2” balsa strip and cut two pieces to form the

trailing edge of the horizontal stab as shown on the plans. Pin these

two pieces in position, making sure they are in-line with each other.

Step 52 - Horizontal Stab Assembly (S2)

Locate both S2’s from BP1. These are

glued in place in the center of the stab,

one on top of the other, resting against

the trailing edge pieces. Glue these in

place.

Step 53 - Horizontal Stab Assembly (S1)

Locate both S1’s from BP1. These are glued

in place in the center of the stab, one on top

of the other, resting against the S2 pieces

you just installed. Glue these in place.

Step 54 - Horizontal Stab Assembly (tips)

Cut both outer tips of the stab from the 1/4” x

1/2” balsa strip you used earlier - one for the left

and one for the right. Glue these in place and pin

them to hold them while the glue cures.

Step 55 - Horizontal Stab Assembly (corners)

Cut four S3’s from BP1. Two are used to create

the front corner on each side. Glue one on

top of the other, then to the tip piece you just

installed.

Pay close attention to their orientation.

Step 56 - Horizontal Stab Assembly (leading edge)

Using 1/4” square balsa,

measure, cut and glue in

the leading edge of the

stab. Check your scrap

pile to see if you have the

proper length first, but if not, use an uncut length.

Step 57 - Horizontal Stab Assembly (bracing)

Using 1/4” square balsa,

measure, cut and glue in center

bracing of the stab. Check your

scrap pile using any possible

shorter lengths first before

reverting to longer, uncut

lengths.