- 54 -

Applicable paper

In order to maintain high quality printing, it is necessary to use paper that fulfills the quality,

thickness and surface finish conditions. Thoroughly test the print quality and paper traction

beforehand, and check that there are no impediments before use.

If the media (paper) is curled or wrinkled before printing, print quality and paper feed

performance cannot be assured.

Paper type, paper size, and paper thickness

•

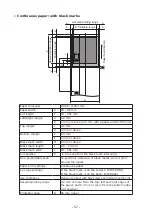

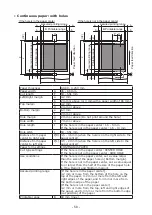

Roll paper specifications

Roll paper type

Paper form

Description

Continuous Paper

A roll of paper

Continuous Paper (Black Mark)

A roll of paper with black marks printed on the back or front side

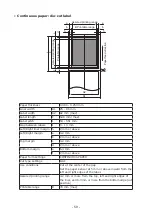

Die-cut Label (Gap)

Paper stamped into a label shape

Paper type

Description

Plain

High-quality paper

Plain label

Labels made of high-quality paper

Glossy label

Labels made of glossy paper

Film label

Labels made of film

Roll paper size

Roll outside diameter

203.2 mm (8 inches) or less in diameter

Paper width

25 - 86 mm (1.0 - 3.4 inches)

Paper thickness

0.08 mm - 0.25 mm (0.0032 - 0.0098 inches)*

Roll core width

Same as the paper width

Roll core inner diameter

50.8 mm or 76.2 mm (2 inches or 3 inches) in diameter

Weight

2.4 kg or less

Printing side

Only the outer side

Notes

Roll end: Roll paper should not be taped or glued to the winding core.

Paper joint: Do not use roll paper with joints in the middle.

* When there is liner, total thickness includes liner.

•

Use paper with black marks printed with carbon ink. Use paper with black marks with a reflectance of 25% or

less. Furthermore, the reflectance of the part without black marks shall be 2.5 times or more of that of the

black mark.

•

Use the die-cut label in the gap mode that meets the following conditions.

The transmittance of the label part (including both the label and the liner) should be 17% or less.

The transmittance of the liner should be 10% or more. Furthermore, the transmittance of the liner shall be

2.5 times or more of that of the label part.

(Both the reflectance and transmittance are values at a near infrared wavelength of 940 nm.)

•

When using the die-cut label in the gap mode, neither the transparent liner or label cannot be used.

•

Use all print media resistant to 25 psi heat/pressure at 210°C for 0.2 seconds. A print medium without

sufficient heat resistance will be deformed by the heat/pressure during fixing, which may cause a paper jam

or malfunction of the machine.

Содержание PRO330S

Страница 1: ...Pro330S Label Printing Manual ...

Страница 19: ... 19 Shaft x1 Ground pin Roll Paper Holder Setup Guide ...

Страница 90: ... 90 7 Install the image drum back to the machine 8 Close the top cover ...

Страница 94: ... 94 10 Install the image drum back to the machine 11 Close the top cover ...

Страница 110: ...7 Cleaning 111 Cleaning the roll paper holder 112 Cleaning the main unit 115 Maintenance ...

Страница 122: ... 122 20 Close the top cover ...

Страница 140: ...EE8001 5120Z002 Rev3 ...