3

INSTALLATION PROCEDURE

NOTE: ‘Wet-set’ is not required to support

the floor under an Oasis product due to the

encapsulated Balsa wood construction.

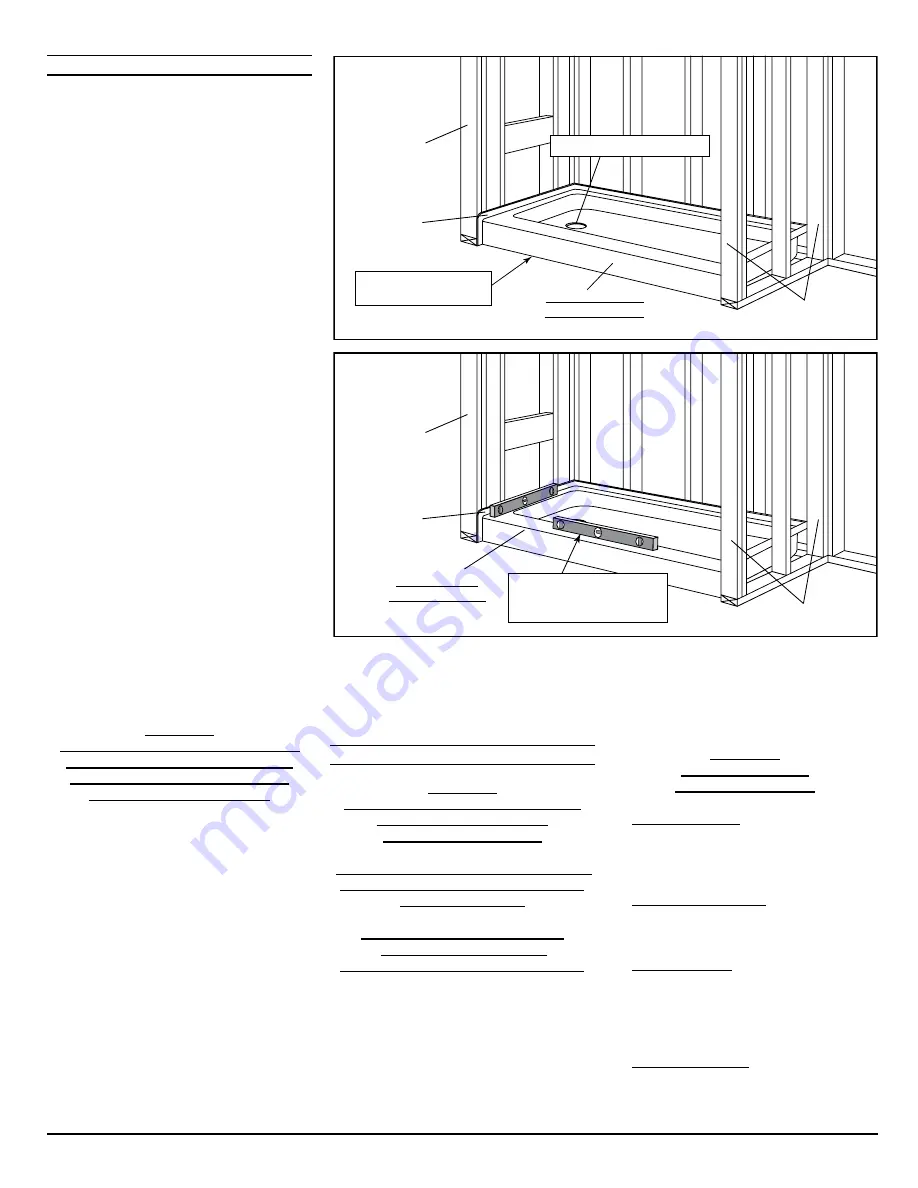

With the unit positioned in the framed area,

several details must be

checked prior to

securing the unit. (Illust. 2 & 3)

l

Confirm the apron/dam is resting flush

on the floor.

l

Confirm drain position.

l

Confirm the unit is level along each side

and across each end.

l

Confirm the unit is square in the framed

installation area.

l

Confirm both inside front corners are

plumb at each end. (This is critical for

proper door installation)

NOTE: The use of a shims behind the nail-

ing flange may be required to ensure the

unit remains square.

After the unit is confirmed level and square

within the framing, drill a 1/8” hole through

the nailing flange at each framing member.

Secure the unit in place across the back

nailing flange first, followed by the sides

and then along the front vertical flanges

(if applicable), using 1-1/4” long nails or

other appropriate fasteners (illust. 4 & 5).

Continually check to make sure the unit

remains plumb within the alcove as it is be-

ing secured.

NOTE: Usage of a thin shield to protect the

unit surface while fastening the unit to the

framing is recommended.

WARNING!

THE INSIDE UNIT SURFACE SHOULD

BE CLEAR OF ALL LOOSE DEBRIS

AND THE SURFACE PROTECTED

BEFORE STEPPING INSIDE.

Water Supply and Drain Connections

Refer to, and follow, the assembly and

installation instructions provided with the

supply valves and drain system. Carefully

check all connections for leaks.

Finishing Guidelines

Filler strips or filler material may be required

over the framing to ensure the under lay-

ment mounts flush over the flanges. A water

resistant under layment is recommended

surrounding the unit. Stop the under lay-

ment 1/16 to 1/8-inch from the unit surface,

and fill the space with a continuous bead of

water resistant sealant. (Illust. 6)

NOTE: Oasis recommends a high qual-

ity silicone based sealant with a mold and

mildew resistant content.

Use care when fastening the under layment

near the unit surface to avoid damage. Seal

the under layment seams and edges, as

required, and install the finish material to

specifications.

UNIT SURFACE CARE

WARNING!

NEVER USE ABRASIVE MATERIALS,

OR ABRASIVE CLEANERS

ON THE UNIT SURFACE!

EXTREME CAUTION is urged regarding

the use of any cleaner, acid or solvent

on the unit surface.

READ AND FOLLOW PACKAGE

INSTRUCTIONS FOR ALL

PURCHASED CLEANING PRODUCTS!

Through routine use, the unit surface can

collect residues from soap, bath additives

and natural body oils. Additional deposits

can also collect from minerals or particles

found in the water. After each use, wipe the

excess water from the unit.This practice

will reduce the buildup of deposits and help

maintain the natural unit lustre.

Following a thorough surface cleaning,

an application of quality automotive wax

will help reduce major accumulations. The

actual schedule for cleaning and waxing will

depend on unit usage and water quality.

WARNING!

NEVER APPLY WAX

TO THE UNIT FLOOR!

u

Routine Cleaning: Mild, non-abrasive

cleaner specifically formulated for gelcoat

and acrylic surfaces recommended. (Rinse

surface thoroughly)

u

Heavy Soap Deposits: Liquid ammonia

household cleaner, applied full strength.

(Rinse surface thoroughly)

u

Stubborn Stains: Liquid household

cleaner or hydrogen peroxide applied

full strength. Place a saturated clean rag

directly on stain and let stand several hours.

(Rinse surface thoroughly)

u

Hard Water Scales: Liquid scale remover

or white vinegar, applied full strength.

(Rinse surface thoroughly)

Nailing

Flange

Wall

Framing

2. Level Unit

In Framed Area

Confirm unit is level

across the front and

at each end.

Wall Framing

1. Position Unit

In Framed Area

Wall Framing

Confirm unit apron is

resting flush on floor.

Nailing

Flange

Wall

Framing

Confirm Drain Alignment

Illustration 2 -

Unit Installation

Illustration 3 -

Unit Installation