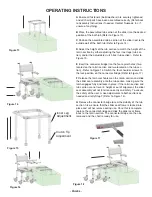

D Cantilever Arms

: The cantilever arms can be adjusted to the

desired height by completing the following steps: Loosen the

socket head cap screws on the arm clamps, raise/lower the

arms accordingly, then re-tighten the socket head cap screws

(Refer to Figure 19). For safety purposes, the cantilever arms

lock in the down position. To switch the arms to the up position,

simply push the arms toward the back of the chair (releasing

the locking mechanism) and lift up (Refer to Figure 20).

E Footrest Assemblies

: Footrest clamps are installed on the

front legs at the factory. Slide the footrest into the clamp.

Loosen the pinch bolt on the footrest clamp and slide up/down

as required by the user’s leg length (Refer to Figure 21).

Figure 19

Figure 20

Figure 21

- PAGE 5 -