4

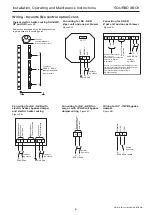

4.0 Wiring - for units with Ecosmart control

08. 06. 18. Leaflet Number 671408

Installation, Operating and Maintenance Instructions

SQURBO XBOX

Unit sizes S2 - S5 with Ecosmart fan only control

Figure 11:

230V-50Hz

Supply

Local isolator

(by others)

N

L

N

L

All inter-connections between circuit

boards, blowers and sensors are made

at the factory.

This diagram only shows the essential

field wiring points for clarity.

Damper Connections

Heat Demand

Signal

Run

Signal

Fault

Signal

Damper Connections

Run

Signal

Fault

Signal

NET

connections

for Ecosmart

devices

Min Max SL run

on

Trickle Test

0

1

Link wire see note*

ES-CO2

Connection

BMS

Input

Signal

0-1

0V

0V

Ecosmart

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

Frost

TX

RX

Extract

N

E

L

SL

DP

CL

N

RET

Heat

Demand Run Fault

NET

connections

for Ecosmar

t

devices

Min Max SL run

on

T ric

kle

T es

t

0

1

Link wire see note*

ES-CO2

Connection

BMS

Input

Signal

0-1

0V

0V

Ecosmart

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

Fr

ost

TX

RX

Supply

N

E

L

SL

DP

CL

N

RET

Heat

Demand

*Remove link wire if switched live signal,

an enabler or BMS signal is connected.

Run

Fault

Unit sizes S2 - S5 with Ecosmart fan and electric

heater control

Figure 12:

230V-50Hz

Supply

Local isolator

(by others)

N

L

N

L

All inter-connections between circuit

boards, blowers and sensors are made

at the factory.

This diagram only shows the essential

field wiring points for clarity.

Damper Connections

Heat Demand

Signal

Run

Signal

Fault

Signal

Damper Connections

Run

Signal

Fault

Signal

NET

connections

for Ecosmart

devices

Min Max SL run

on

Trickle Test

0

1

Link wire see note*

ES-CO2

Connection

BMS

Input

Signal

0-1

0V

0V

Ecosmart

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

Frost

TX

RX

Extract

N

E

L

SL

DP

CL

N

RET

Heat

Demand Run Fault

NET

connections

for Ecosmar

t

devices

Min Max SL run

on

T ric

kle

T es

t

0

1

Link wire see note*

ES-CO2

Connection

BMS

Input

Signal

0-1

0V

0V

Ecosmart

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

Fr

ost

TX

RX

Supply

N

E

L

SL

DP

CL

N

RET

Heat

Demand

*Remove link wire if switched live signal,

an enabler or BMS signal is connected.

Run

Fault

Heater Temperature

Setting

C

o

15

20

25

30

NET

connections

for Ecosmart

devices

Min Max SL run

on

Trickle Test

0 1

ES-CO2

Connection

BMS

Input

Signal

0-1

0V

0V

Ecosmart

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

Frost

TX

RX

Extract

N

E

L

SL

DP

CL

N

RET

Heat

Demand Run Fault

NET

connections

for Ecosmart

devices

Min Max SL run

on

Trickle Test

0 1

ES-CO2

Connection

BMS

Input

Signal

0-1

0V

0V

Ecosmart

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

Frost

TX

RX

Extract

N

E

L

SL

DP

CL

N

RET

Heat

Demand Run

Fault

N

E

L

SL

Fault

Client

wiring

EXTRACT FAN

STANDBY FAN

RELAY STANDBY

S2T to S5T Twinfans all variants

Figure 13: