86

Part 13 - Troubleshooting

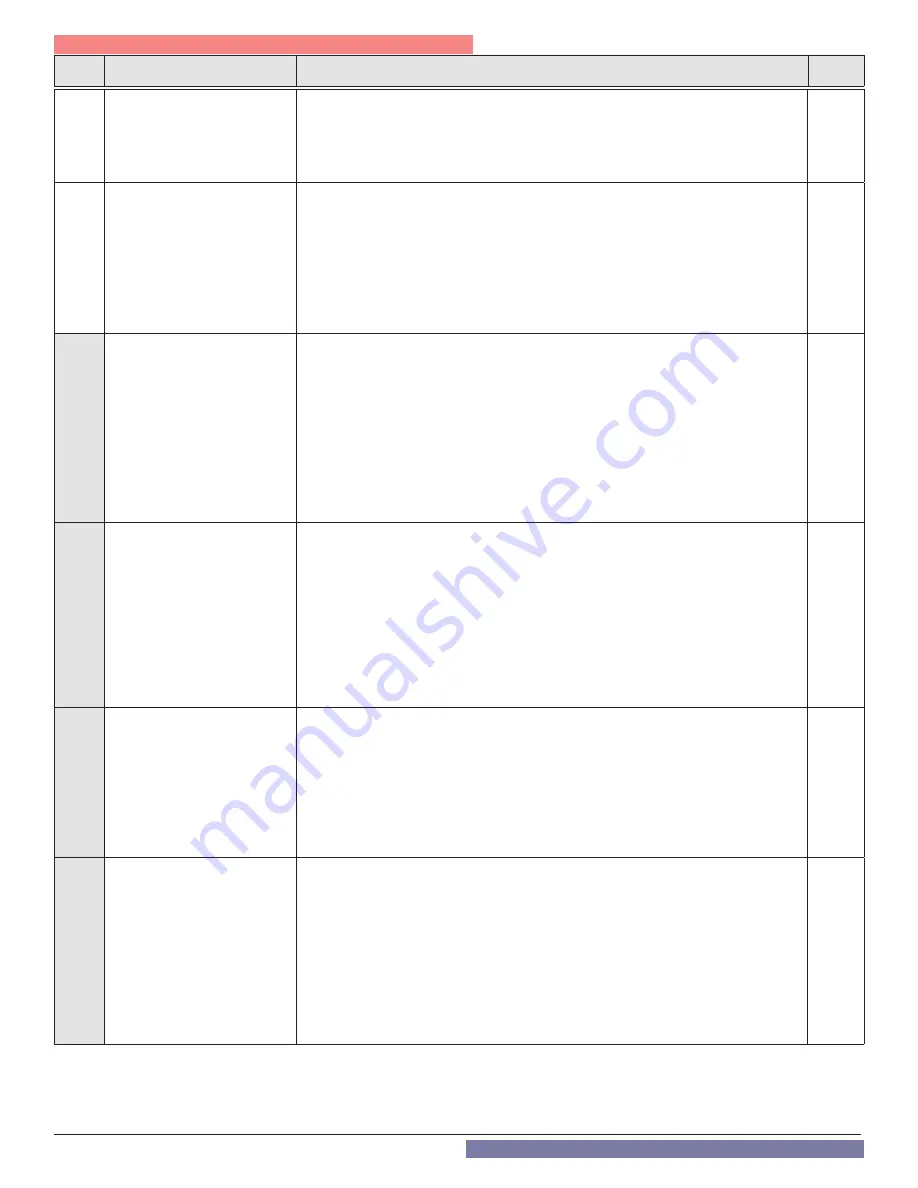

5 02

Flame detected with gas valve

closed

This Error Code will go away when the condition is remedied.

1. If Error happens again disconnect the flame detection electrode. Then press Reset.

2. If the error does not happen again replace the flame detection

electrode.

3. If the error happens again replace the main PCB.

Blocking

(Auto

Reset)

5 04

Detection of 10 flame lifts in one

operating cycle

Press Reset to clear the error code.

If Error happens again:

1. Monitor the gas pressure to the appliance while in operation. Ensure pressure is between 3.5 and

10.5” WC.

2. Check gas valve wire. Ensure connection is secure.

3. Check flame detection sensor. Ensure connections are secure. Normal operating settings are more

than 2.5DC before ignition, less than 2.5DC after ignition.

4. Check vent terminations. Ensure there are no blockages.

5. Ensure that the flame is stable when lit.

6. If the problem persists, replace the main control.

Blocking

(Manual

Reset)

5 P1

1st Ignition Failed

1. Monitor the gas pressure to the appliance while in operation. Ensure pressure is between 3.5 and 10.5” WC

(Natural Gas), or between 8 and 13” WC for boilers converted to Propane (LP) operation.

2. Check gas valve wire. Ensure connection is secure.

3. Check flame detection sensor. Ensure connections are secure.

Normal operating settings are more than 2.5DC before ignition;

less than 2.5DC after ignition.

4. Check igniter transformer for proper connection.

5. Clean the spark igniter with steel wool to remove oxides. Ensure

proper separation (2/16”-3/16”).

6. Replace the spark igniter if damaged.

7. Ensure that the flame is stable when lit.

8. If the problem persists, replace the main control.

Warning

5 P2

2nd Ignition Failed

1. Monitor the gas pressure to the appliance while in operation. Ensure pressure is between 3.5 and 10.5” WC

(Natural Gas), or between 8 and 13” WC for boilers converted to Propane (LP) operation.

2. Check gas valve wire. Ensure connection is secure.

3. Check flame detection sensor. Ensure connections are secure.

Normal operating settings are more than 2.5DC before ignition;

less than 2.5DC after ignition.

4. Check igniter transformer for proper connection.

5. Clean the spark igniter with steel wool to remove oxides. Ensure

proper separation (2/16”-3/16”).

6. Replace the spark igniter if damaged.

7. Ensure that the flame is stable when lit.

8. If the problem persists, replace the main control.

Warning

5 P3

Detection of Flame loss during run

1. Monitor the gas pressure to the appliance while in operation. Ensure pressure is between 3.5 and 10.5” WC

(Natural Gas), or between 8 and 13” WC for boilers converted to Propane (LP) operation.

2. Check gas valve wire. Ensure connection is secure.

3. Check flame detection sensor. Ensure connections are secure.

Normal operating settings are more than 2.5DC before ignition,

less than 2.5DC after ignition.

4. Check vent terminations. Ensure there are no blockages.

5. Ensure that the flame is stable when lit.

6. If the problem persists, replace the main control.

Warning

5 P6

3rd and 4th Ignition Failed

1. Monitor the gas pressure to the appliance while in operation. Ensure pressure is between 3.5 and

10.5” WC (Natural Gas), or between 8 and 13” WC for boilers converted to Propane (LP) operation.

2. Check gas valve wire. Ensure connection is secure.

3. Check flame detection sensor. Ensure connections are secure.

Normal operating settings are more than 2.5DC before ignition;

less than 2.5DC after ignition.

4. Check igniter transformer for proper connection.

5. Clean the spark igniter with steel wool to remove oxides. Ensure

proper separation (2/16”-3/16”).

6. Replace the spark igniter if damaged.

7. Ensure that the flame is stable when lit.

8. If the problem persists, replace the main control.

Warning

Display

Description

Possible Remedies

Error

Type

Содержание TRX150

Страница 98: ...98 Maintenance Notes...