INST6200 – 4/04

Installation / Operation / Maintenance

Staticmaster

®

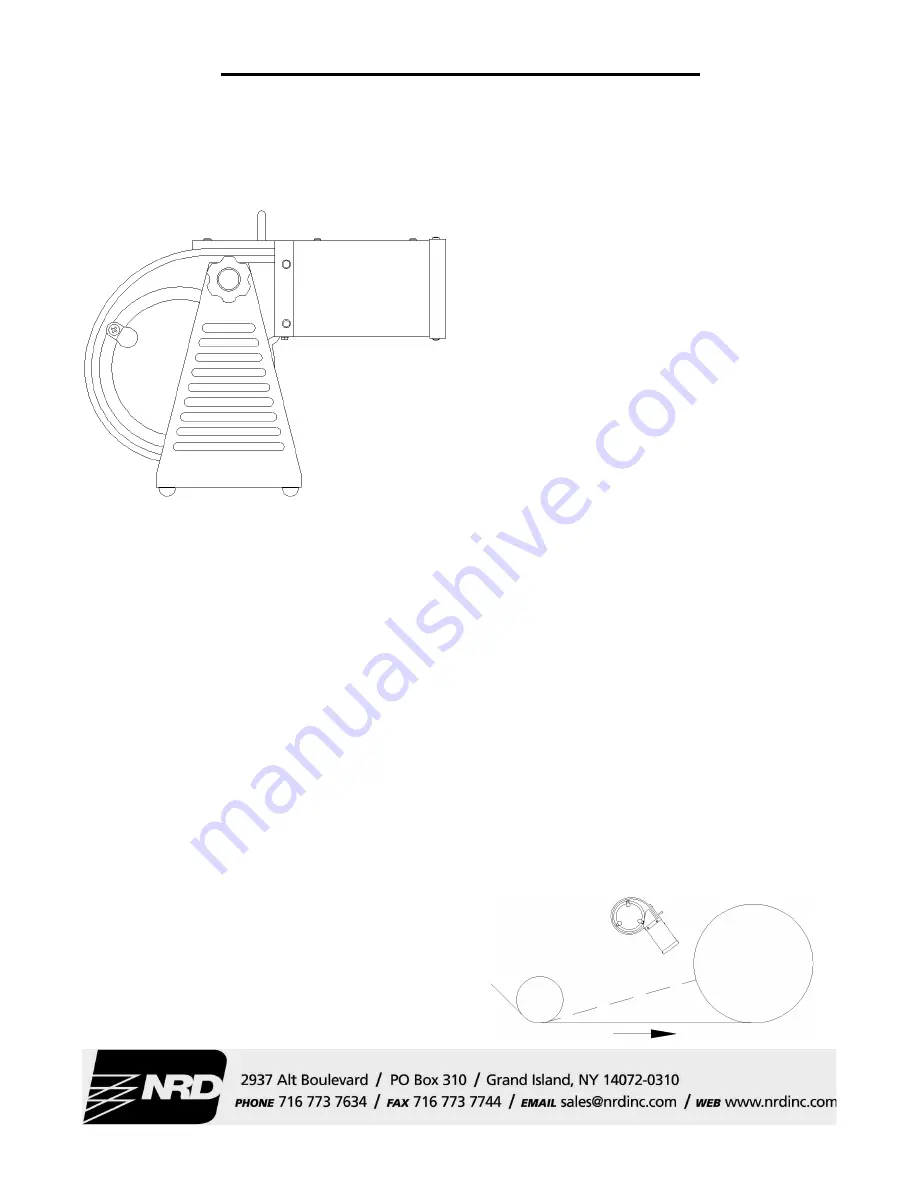

Model 6200HOB Ionizing Air Blower

General Guidelines

•

Make sure that the line voltage used to supply

power to the Staticmaster

®

6200HOB is

correct. It is essential to the performance of

the unit and to the safety of the operator that

the unit is properly grounded. Proper

grounding is accomplished by inserting the

line cord into a mating receptacle equipped

with a known, properly connected ground.

CAUTION: Do not remove the ground

prong from the line cord!

•

Overall, keep the unit clean and free of water,

oil,

grease, and other contaminants that may

cause the unit to short circuit, reduce

efficiency, and shorten the useful life of the

unit.

•

Clean the ionizing points routinely for

optimum performance.

CAUTION: Turn the power off while and

whenever brush cleaning the emitter points.

The length of time between routine cleaning

will vary according to the cleanliness of the

environment. In most applications, a quick

brushing (or blow out with a compressed air

gun) once each month is adequate.

Installation

Initial set-up and Positioning

Proper location and positioning of the

Staticmaster

®

6200HOB is essential to satisfactory

performance and to the life of the equipment.

Because each application is somewhat unique,

careful thought should be given to establish the

best location and installation.

Most of the time, the best place to install any type

of static control equipment is immediately ahead

of the problem. For example, if an operator is

getting shocked from a rewound roll, then the

ionizer should be placed so that the last thing the

material passes before it winds onto the roll is the

ionizer. The advantage of the Staticmaster

®

6200HOB Ionizing Air Blower is that (unlike a

static bar that must be mounted within inches of

the material) it can effectively neutralize an

electrostatically charged material from a distance

of several feet. This means that the material will

be in the effective range of a properly mounted

Staticmaster

®

6200HOB from the time it starts

winding until it is fully wound.