N1500FT Flow Indicator

NOVUS AUTOMATION

2/8

•

Open Sensor –

I.error

The open sensor alarm operates whenever the input sensor is badly

connected or broken. Valid only for 4-20 mA inputs.

•

Minimum Value –

Lo

It sets off when the reading is below the value determined by the

alarm Setpoint.

•

Maximum Value –

Ki

It sets off when the reading is above the value determined by the

alarm Setpoint.

•

Feeder Function –

FEEDER

It activates the output relay when it is started by pressing

or

via the auxiliary digital input (according to setup) and deactivates

when the reading reaches the value determined by the alarm

Setpoint.

ALARM TIMER

The indicator allows setting up an Alarm Timer, where users can set

the alarm to go off with a delay, to go off in only one pulse or to go off

in sequential pulses.

Figures in Table 1 show these functions. There, times T1 and T2

may vary from 0 to 32000 seconds and are defined while

programming the indicator. For regular operation of alarms, without

timers, simply set T1 and T2 to 0 (zero).

he alarm light signals will be displayed whenever there is alarm

condition, regardless of the current status of the output relay, which

may be temporarily out of power because of the timer function.

ADVANCED

FUNCTION

T1

T2

ACTION

Regular

Operation

0

0

Delay

0

1 to 32000

Pulse

1 to 32000

0

Oscillator 1 to 32000 1 to 32000

Table 1 - Alarm timer functions

ALARM HYSTERESIS

Hysteresis defines the difference between the value measured when

the alarm is triggered and the value at which it is deactivated.

INITIAL ALARM BLOCK

The initial block option prevents the alarm from going off in case there

is alarm condition at the time the indicator is being energized. The

alarm may be triggered only after a non-alarm condition is followed by

an alarm condition. This function is not valid for alarms programmed as

Open Sensor.

SPECIAL FUNCTIONS

MAXIMUM AND MINIMUM

The flow indicator continuously records the minimum and maximum

values of instantaneous flow rate. These values can be viewed on

the first screen of the main cycle by pushing

and

,

respectively. The

key can be set to zero maximum and

minimum values.

FEEDER

The feeder function is used to control the volume of fluids based on

its flow rate. It is typically used for storage applications, where there

is a start signal that triggers a relay and the flow rate begins to be

measured. When reaching a given setpoint, this relay is deactivated

to stop flow.

Its use depends on correct configuration of related alarm.

AUXILIARY DIGITAL INPUT AND

KEY

Similarly to a digital input, the

key can be set to zero the

totalizer, freeze the main screen, zero minimum and maximum

readings or trigger the feeder function.

MANUAL OPERATION MODE

In the hardware cycle, outputs can be set manually. This can be

extremely useful for tests and simulations. After exiting the cycle,

outputs go back to their regular status.

24 VDC AUXILIARY POWER SUPPLY

DC power supply models provide a 24 Vdc output for field transmitters.

INSTALLATION

The indicator must be installed on a panel. To do so, remove the two

plastic clamps, introduce the device in the panel cutout and put the

clamps back from the rear side of the indicator.

INSTALLATION RECOMMENDATIONS

•

Input signal conducers should be disposed in the system

separately from output conducers and power conducers,

preferably in grounded electrodes.

•

Instruments should be powered through a dedicated network.

•

For control and monitoring applications it is vital to consider what

might happen if any part of the system fails. The alarm internal

relay does not ensure total protection.

•

It is recommended to use RC FILTERS (47

Ω

and 100 nF, series)

in contactor coils, solenoid coils, etc.

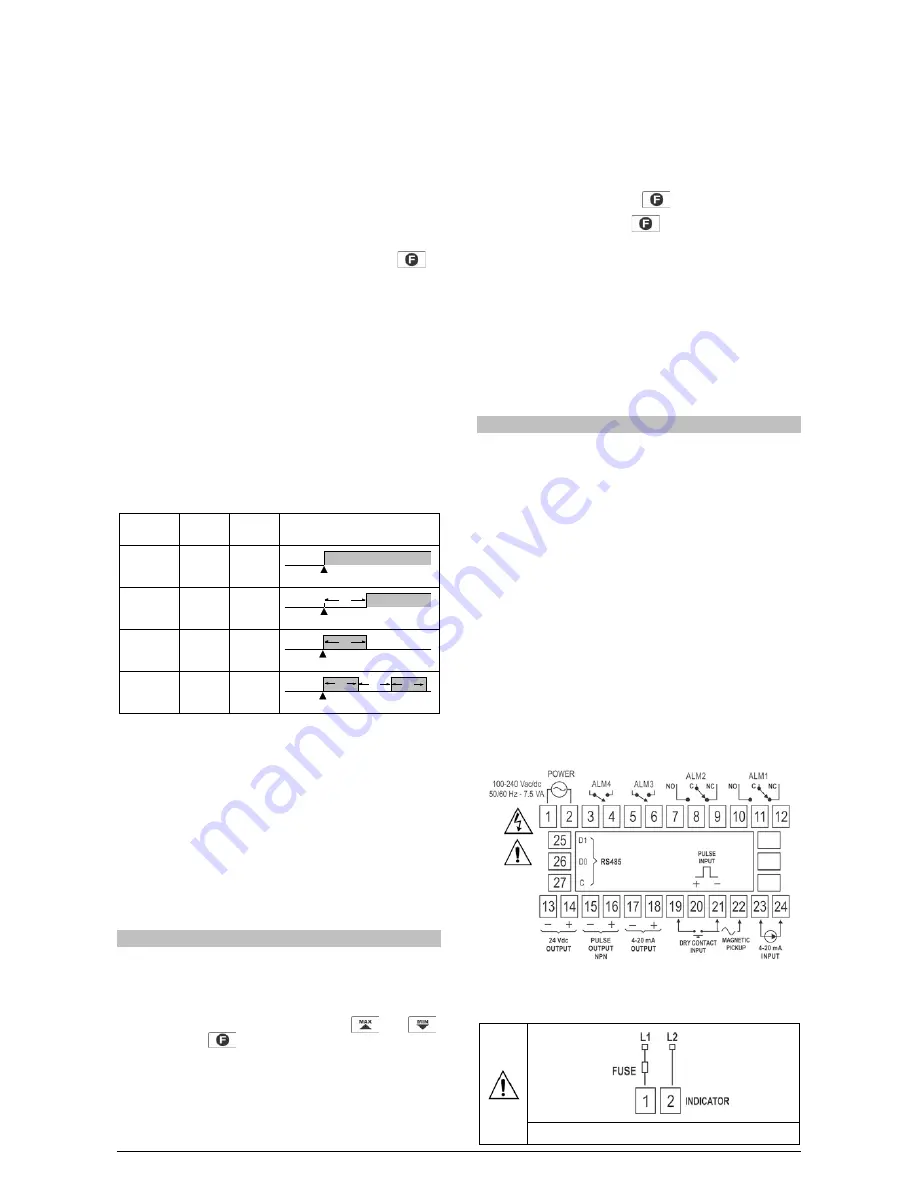

ELECTRICAL CONNECTIONS

All the inside can be removed without the need to undo the electrical

connections. Disposition of signals in the rear panel of the indicator is

shown in Fig. 1.

Fig. 1 – Rear panel connections

POWER SUPPLY CONNECTION

Fig. 2 – Power supply terninals

Alarm Event

Alarm

Output

Alarm Event

Alarm

Output

T2

Alarm Event

Alarm

Output

T1

Alarm Event

Alarm

Output

T1

T2

T1