009NP006.DOC

SAFETY INSTRUCTIONS FOR HYDRAULIC EQUIPMENT

1.

Please read the operating instructions.

Acquaint yourself with the hydraulic equipment.

2.

Provide the equipment with the necessary care.

Always keep the equipment in operational condition.

Cleanness is an essential requirement for good and safe working.

3.

Switch off the electric power supply to the hydraulic equipment,

•

when the equipment is not in use

•

when maintenance work is to be carried out.

4.

Avoid unintentional switching - on.

Keep hands and feet away from the switch when the equipment is not being used.

5.

Do not use the equipment in a manner in contravention of the instructions.

Never carry the equipment by the pipe or pull on the pipe.

Protect the piping from heat, oil, sharp edges and high levels of weight strain.

6.

Use only piping, fittings and accessories wich have been designed for the operating pressure of

the hydraulic unit.

BURSTING PRESSURE OR TEST PRESSURE IS

NOT

OPERATING PRESSURE!

Avoid squashing or bending of the piping.

Piping must not be painted over.

7.

Replace the hydraulic piping

•

when cracks, squashed or bent points are to be seen

•

when blistering is established

•

when hydraulic fluid escapes

•

when pipe fittings are damaged

•

when discolouration is established on the outer layer,

e.g. due to the influence of solvents.

8.

The hydraulic fluid used in the system is kerosene-based.

This requires particular care and attention.

•

Avoid continuous contact with the skin

•

ensure that the hydraulic fluid does not get into the eyes or mouth.

Hydraulic pipes have to be replaced after 5 years of usage, despite of the circumstance that no

damages should be remarkable.

9.

The equipment must not be operated, if it has leaks and there is a danger of hydraulic fluid

coming into contact with persons, open fire, heating equipment, electric cabling, ground water,

foods and other substances which are intended for human consumption.

10. Hydraulic units with petrol engines

•

must not be operated in closed rooms, due to the

DANGER OF INTOXICATION!

•

do not pour in petrol while the motor is running or in the vicinity of open fire.

DANGER OF EXPLOSION!

Содержание HP 300

Страница 1: ...01000 R06eng 0704 Repair Instructions and Spare Parts Lists for PRESSING CYLINDERS 16566 ...

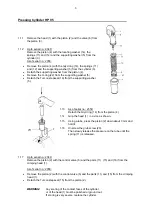

Страница 11: ...7 3000 Pressing Cylinder HP 95 up to serial no 2349 ...

Страница 13: ...9 3000 Pressing Cylinder HP 95 as of serial no 2350 ...

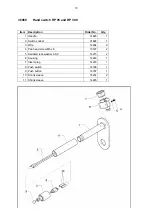

Страница 15: ...11 31830 Hand switches HP 95 and HP 300 old ...

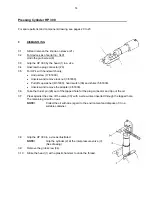

Страница 23: ...19 1000 Pressing Cylinder HP 300 up to serial no 3400 ...

Страница 25: ...21 1000 Pressing Cylinder HP 300 as of serial no 3401 ...

Страница 30: ...26 ...

Страница 33: ...29 5200 Pressing Cylinder HPM 400 ...

Страница 37: ...33 ...

Страница 39: ...35 3850 Pressing Cylinder HP 450 ...

Страница 41: ...37 31831 Hand Switch HP 450 old ...