深圳市诺瓦机器人技术有限公司

Shenzhen Nova Robot Technology Co., Ltd.

44

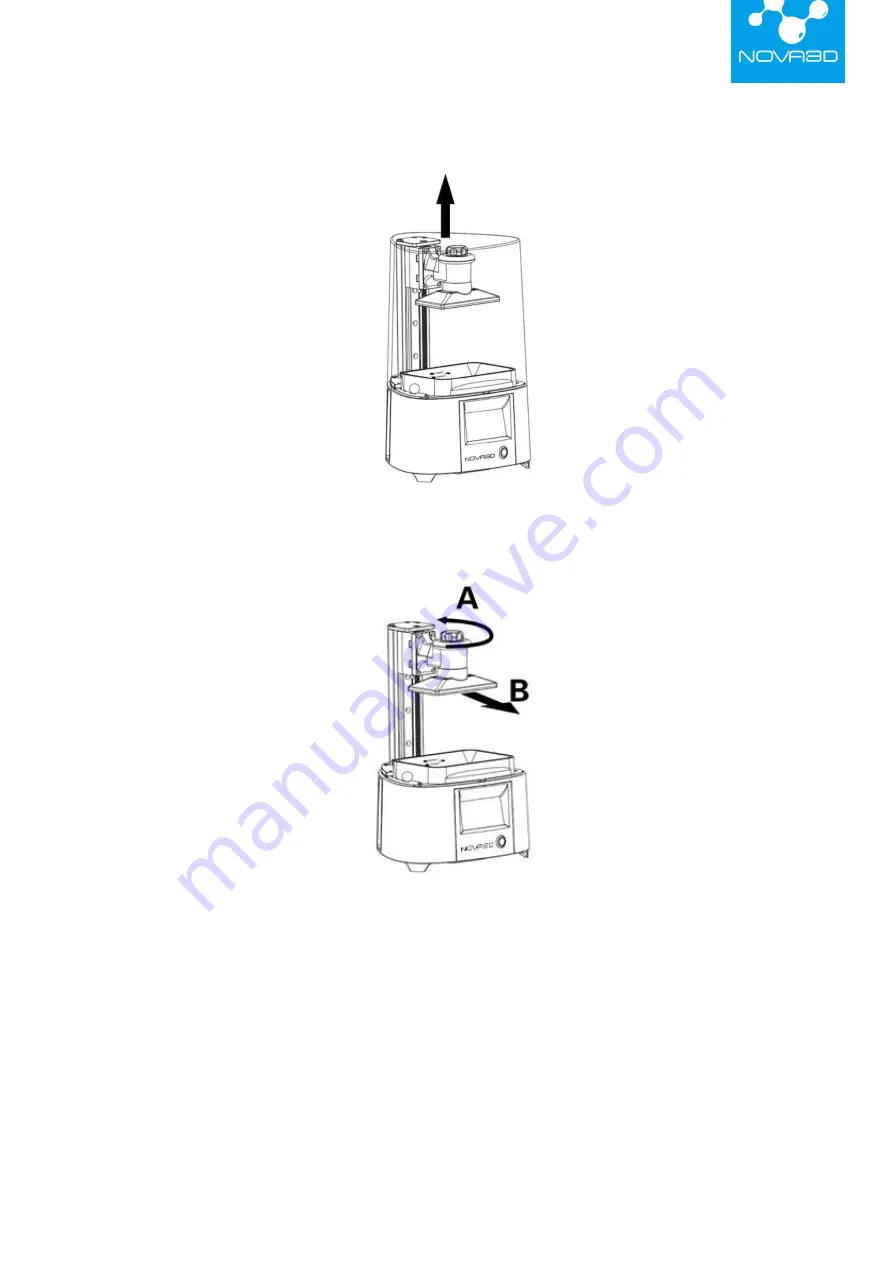

4. Wipe the top and edges of the platform with a paper towel and unscrew the platform screw.

Remove the platform. Be careful not to spill the liquid resin on the printer and its surroundings.

5. Install the UV cover on the printer to prevent the UV light from curing the resin in the vat.

Содержание ELFIN

Страница 1: ...ELFIN User Manual...

Страница 9: ...8 2 What s in the Box...

Страница 11: ...10 3 Main Components Front View Schematic diagram of the front of the device...

Страница 12: ...11 Back view Schematic diagram of the back of the device...

Страница 26: ...25...

Страница 27: ...Shenzhen Nova Robot Technology Co Ltd 26...

Страница 41: ...Shenzhen Nova Robot Technology Co Ltd 40...