CAUTION:

Disconnect tool from air supply be fore performing

any Se rv ic e Procedure.

PROBL EM

Air leak ing near top of

tool or a t trigger area .

Tool do es nothing or

operate s sluggishly.

Air leak ing near botto m of

tool.

Tool jam ming freque ntly.

Other.

PROBLE M CAUSE

Loose scr ews.

O-ring or seal is worn o r

damaged .

Inadequa te air supply.

Inadequa te lubrication .

O-rings o r seal is worn or

damaged .

Loose scr ews.

O-rings o r seal is worn or

damaged .

Incorrect fasteners.

Damaged fasteners.

Magazine or nose

screws lo ose.

Magazine is dirty.

Driver is w orn or dama ged.

8. NE VER USE OXY GEN, CAR BON

DIOXI DE

, combu stible gas es or any

other bottle d gas as a p ower sourc e for

t h i s

t o o l :

e x p l o s i o n a n d

s e r i o u s

perso na l i nj ury cou l d res ult.(F ig.3)

(F ig.5)

9 . O N L Y

D I S C O N N E C T

Q U I C K

CONNECTOR

10.DI SCON NECT TO OL F ROM AIR

SU P P LY H O S E

a t the body tail portion

a i r

i n l e t ,

s i n c e

d i s c h a r g e

o f

compr essed air c anno t be g uaran teed.

If ope rating is no t corr ect, the too l can

remai n cha rged with air a fter being

discon nected and still b e abl e to dr ive a

fas t e ne r,

ca u s i ng p er s o n al i n ju r y.

( F i g . 4 )

b e f ore d oi ng to o l

ma i n t e n a n c e ,

c l e a r i n g a j a m m e d

fasten er, leaving work are a, m oving

tool to anot her lo cation , or h andin g the

car efully

check if there is any p art d amag ed to

obtain idea l resul ts. Do not u se the tool

i f t h e t o o l h a s a n y a i r

l e a k ag e ,

dama ged p arts or

tool to anot her p erson .

n eeds repa iring.

10

3

CAUTI ON:

Disconnect tool from air supply before cleaning and

i n spe c ti o n . C or r ect al l pr o bl ems

be for e o p er at in g .

Wipe the tool clean and inspect for wear or damage. Use non-flammable

cleaning solutions to wipe exterior of tool only if necessary. Do not soak

tool with cleaning solutions, since such solutions can damage internal parts.

Inspect trigger and safety mechanism to assure system is complete and

Keep all screws tight. Loose screws can cause personal injury or damage tool.

If tool is used without an in-line oiler: place 5 or 6 drops of pneumatic tool oil

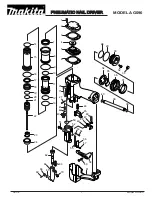

All quality tools eventually require servicing of replacement of parts due to

wear from normal use. Some user serviceable components are described in

the TROUBLE SHOOTING Section. All repairs made by local agencies are fully

guaranteed against def ecti ve material and workmanship. We cannot

guarantee repairs made or attempted by anyone other than these agencies.

Should you have any questions about your tool, please contact with us at any

time. In any communications, please give all information shown on the

CORRECTIO N

Tighten screw s.

Supply adequ ate air suppl y.

Place 5 or 6 d rops of oil int o air inlet.

Install

“

TOP

”

Maintenance Kit.

Tighten screw s.

Supply appro ved fastener s of correct

size.

Replace unda maged faste ners.

Tighten screw s.

Clean magaz ine.

Contact a loc al agencies.

Replace dam aged or worn components .

Replace dam aged or worn components .

Replace dam aged or worn components .

Fig.5

Fig.6

Fig.7

Fig.4

W ARNI N G !

Wear ANSI appro ved im pac t

gogg les.

Di sco nnec t

from

air

supply

w he n

s er vi c i n g ,

c l e ar i ng

jams , or no t usi ng .

Do no t use oxy ge nor

comb us ti bl egas s es.

Remo v e f i nger f rom t rigger ,

when not op eratin g.

MAINTENANCE

CLEAN AND INSPECT DAILY

SERVICE AND REPAIRS

in to th e ai r in let o f the too l at th e be ginn ing of each work da y.

functio nal: no lo ose or mis sing pa rts, n o b ind ing or sticking parts.

n ame pla te of y our tool (mo de l num ber, type , s e rial n umb er, etc.).

TROUBLE SHOOTING