8.

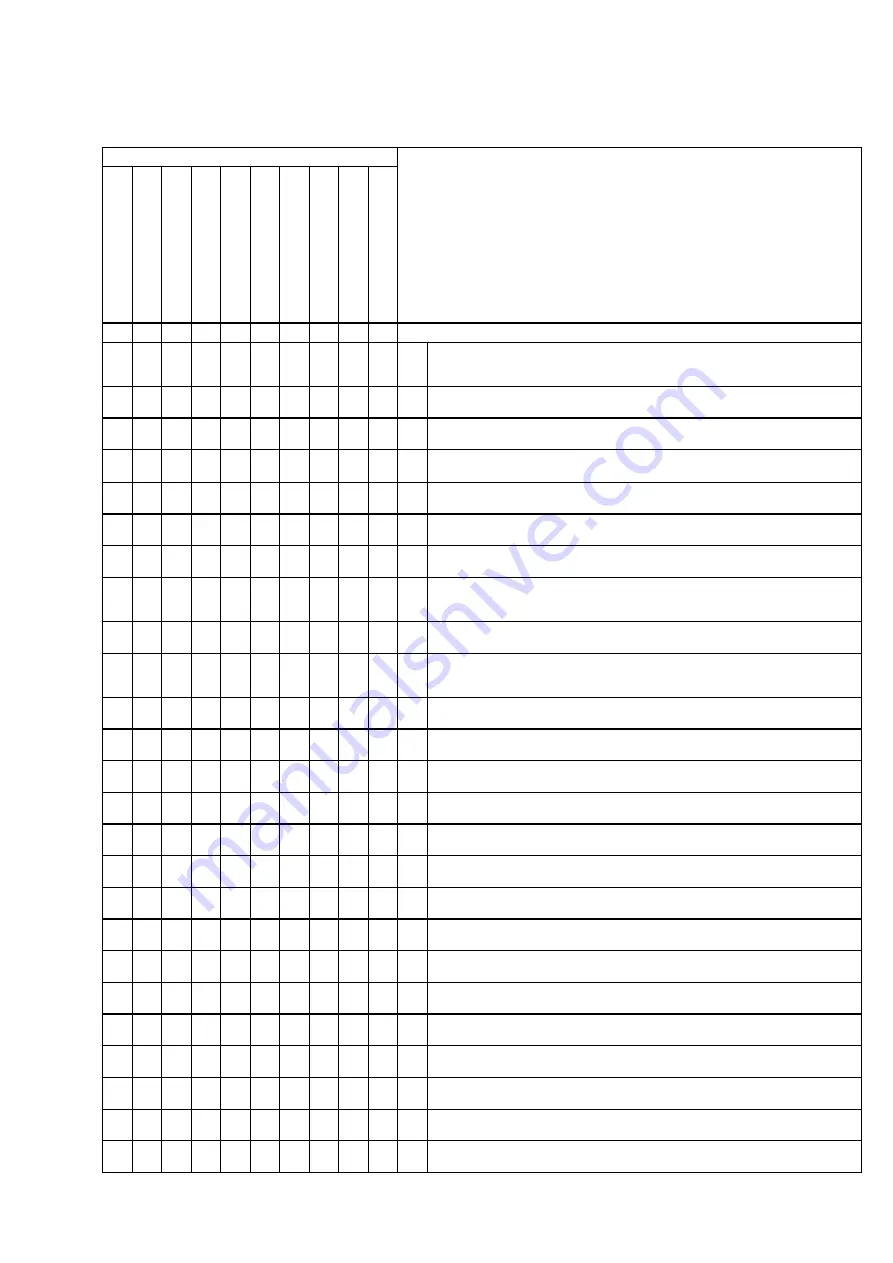

Breakdown, reasons, remedies

Breakdown

pum

p has no sucti

o

n

pum

p conveys ir

re

gular

ly

the conveying capacity is not

achieved

pr

essur

e

is not achieved

pum

p does not star

t

pum

p has sei

z

e

d or

has

stopped conveying

pum

p oper

a

tes noi

si

ly

mo

to

r b

e

c

o

me

s

t

o

o

w

a

rm

the stator

wear

s out ear

ly

shaft sealing leaks

1

2

3

4

5

6

7

8

9

10

Reasons / Remedies

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

s

t

u

v

w

x

y

seepex progressive cavity pumps will operate trouble-free if

they

are used in accordance with our data sheet (see item 9) and

our operating and maintenance instructions:

Check rotational direction of the pump per data sheet and nameplate.

In case of wrong direction, change wiring of motor.

Suction pipe or shaft sealing leak. Eliminate the leakage.

Suction head too high (item 6.5.3.1). Check suction head with vacuum gauge.

Increase the suction pipe diameter and fit larger filters. Open the suction valve

Viscosity of the liquid too high.

Check and accommodate per data sheet.

Wrong pump speed.

Correct pump speed per data sheet.

Avoid inclusions of air in the conveying liquid.

Pressure head too high (point 6.5.3.2). Check pressure head with manometer.

Reduce the pressure head by increasing the pressure pipe diameter or by

shortening the pressure pipe.

Pump runs partially or completely dry (point 6.5.2). Check flow in the suction

chamber. Install dry running protection TSE.

Check coupling, possibly pump shaft is misaligned to drive. Check whether

coupling gear is worn. Realign coupling. The coupling gear has perhaps to be

replaced.

Speed too low. Increase the speed when high suction performances are

required and when the liquid is very thin.

Speed too high. Reduce the speed when pumping products with high

viscosities - danger of cavitation.

Check the axial play in the coupling rod linkage. Check that the bush has been

installed correctly see document OM.PJT.__e item 2.2

Check for foreign substances in the pump. Dismantle the pump, remove

foreign substances and replace worn parts.

Stator or rotor worn. Dismantle the pump and replace defective parts.

Joint parts worn. Replace worn parts and fill with special pin joint grease .

Suction pipework partially or completely blocked. Clean suction pipework.

Temperature of the pumping liquid too high. Excessive expansion of the stator.

Check temperature and install rotor with diameter smaller than specified.

Gland packing too strongly tightened or worn. Ease or tighten stuffing box.

Replace defective packing rings.

Solid contents and/or size of solids too large. Reduce pump speed and install

perhaps a screen with suitable meshes. Increase fluid share.

When the pump is non operational the solids settle out and become hard.

Clear and flush the pump immediately.

The liquid becomes hard when temperature falls below a certain limit. Heat the

pump.

Stator swollen and unsuitable for the pumped liquid. Select a suitable stator

material. Use perhaps rotor with diameter smaller than specified.

The bearing in the drive casing of the pump or in the drive engine is defective.

Replace bearing.

Mechanical seal defective. Check seal faces and O-rings. If necessary replace

corresponding defective parts.

Adhesion between rotor and stator excessive (as delivered).

Lubricate (soft soap, genuine soap) between stator and rotor.

Then turn the pump by means of the tool W2 .

OM.REC.01e

1 (1)

A / 05.01.95

Operating and Maintenance Instructions

Progressive Cavity Pump

Dokument

document

Blatt

sheet

Ausgabe

issue