8

4. Place the horizontal drain pan on the opposite side of

the coil. On units with 2 sets of knockouts, remove the

other set of knockouts in the coil spacing plates and

insert support rod.

5. Slide the coil and the horizontal drain pan assembly

back into the unit. Re-attach the tube close off plate.

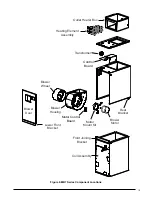

note: For A-size cabinet applications, it may be

preferrable to remove the blower assembly prior

to installing the coil & drainpan. In this case follow

instructions 1-4 as listed above but also remove the

blower access door and blower assembly. The blower

assembly is secured with two screws on either side

near the front. With these removed the blower assembly

can slide out of the front of the unit. Install the coil and

drain pan as described in step 5 and then replace the

blower assembly. Take care to ensure that the flanges

on the sides of the blower assembly are captured by

the pockets in the blower deck. It may be necessary

to lift the blower assembly during insertion to allow the

lower blower leg to clear the side of the drain pan. The

blower will stop against the back of the blower deck.

Replace the two screws and the blower access door

and procede with steps 6-9.

6. Remove the plug from one of the threaded holes

in the horizontal drain pan. Completely remove the

webbing located in the threaded holes of the drain

pan. iMPortant: If the webbing is not removed, the

condensate will not drain properly and ceiling damage

may occur.

7. Insert the plug (from horizontal drain pan) into the open

and unused drain hole in the drain pan at the bottom

of the unit to block bypass air.

8. Remove the corresponding drain line knockout from

the coil access door to allow access to the horizontal

drain.

9. Replace the door and attach the drain line.

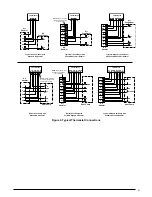

Horizontal installation

MB7 air handlers are shipped from the factory ready

for horizontal left applications and horizontal right

applications. The blowers can be installed horizontally

in an attic, basement, crawl space or alcove. They can

also be suspended from a ceiling in a basement or utility

room in either a right to left airflow or left to right airflow.

A typical installation of the unit in a suspended horizontal

application is shown in Figure 5.

When mating the blower and coil for horizontal left or

right applications, reference the upflow instructions on

page 6. Make sure to account for the coil orientation by

configuring the coil drain pan assembly properly. Multi-

position procedures are also available in the cased coil

Installation Instructions supplied with the unit.

noteS:

• In many applications when joined with a C6 cased

coil, the shorter horizontal drain pan extension which

is included with the MB7 must be used. This is to avoid

any interference with the extension included with the

C6 and the blower.

• The

air handler may or may not be shipped from the

factory with all the parts required for horizontal left

applications and horizontal right applications. If your

unit does not have parts for a horizontal application, a

kit may be available.

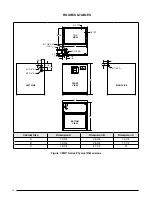

If suspending the air handler from the ceiling, assemble

a support frame (Figure 5) using slotted iron channel and

full threaded rod. Fasten the frame together with nuts,

washers, and lockwashers. Secure the support frame

to the rafters with lag bolts. The air handler can also be

suspended using steel straps around each end of the

unit. The straps should be attached to the air handler with

sheet metal screws and to the rafters with bolts.

Horizontal Left Installations

1. Remove the coil access door.

2. Remove the plug from one of the threaded holes in the

horizontal drain pan. Completely remove the webbing

in the threaded holes of the horizontal drain pan. if the

webbing is not removed, the condensate will not

drain properly and ceiling damage may occur.

3. Insert the plug (from horizontal drain pan) into the open

and unused drain hole in the drain pan at the bottom

of the unit to block bypass air.

4. Remove the corresponding drain line knockout from

the coil access door to allow access to the horizontal

drain.

5. Replace the door and attach the drain line.

Horizontal Right Installations

1. Remove the coil access door. Unscrew the line-set tube

close-off plate from the front left cabinet rail.

2. Slide the coil and drain pan assembly out of the unit.

3. Remove the sheet metal hairpin covers (if supplied)

from the back of the coil and discard.

Figure 5. unit Horizontally Suspended

Threaded

Rod

Lag

Bolt

Nuts (x2)

Washer

and

Lockwasher

Nuts (x2)