10

on an outside wall or any other location where its

operation may be adversely affected by radiant heat from

fi replaces, sunlight, or lighting fi xtures, and convective

heat from warm air registers or electrical appliances.

Refer to the thermostat manufacturer’s instruction sheet

for detailed mounting and installation information.

• Install the grommet (packed with the unit) in the hole

for low-voltage wires. Connect the low-voltage wiring to

the thermostat and the outdoor unit and the appropriate

screw terminal located on the control board.

NOTE:

When the low voltage wires are positioned in this

grommet, the grommet will prevent chafi ng and/or

shorting of the low voltage leads.

Important!

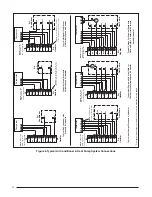

On variable speed models when the unit is

used in an air conditioning system, connect the

O

terminal

to the

Y

terminal. See Figure 6 (page 12)

.

Control Board

The control board in the indoor blower controls the timing

sequence of the elements. Depending on the thermostat

connection, there are multiple timing sequence variations

that can be chosen. See Table 3 (page 11) for element

sequence timing. The board also is equipped with a 3

second blower on delay and a 15 second blower off delay.

See Figures 9 - 11 (pages 21 & 22).

Twinning

MB6 indoor blowers are not supplied with a built in twinning

capability. To connect two indoor blowers to a common

single stage AC condensing unit or heat pump, a twinning

kit is available for fi eld installation.

Please follow the

instructions supplied with the kit.

NOTE:

Variable speed indoor blowers cannot be twinned.

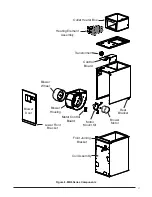

Heater Kits

Field-installed electric heater kits are available. Instructions

for installing the electric heaters are included with the

heaters. See heater kit information can be found in the

Technical Specifi cations.

Indoor blowers set up with 15 kw or more of electric heat

will normally be confi gured for multiple-circuit power supply.

They may, however, be connected to a single-circuit power

supply with the addition of a single circuit accessory kit

(See Technical Specifi cations). Select the wire size and

over-current protection in accordance with the minimum

circuit ampacity and maximum over-current protection

shown in Table 2.

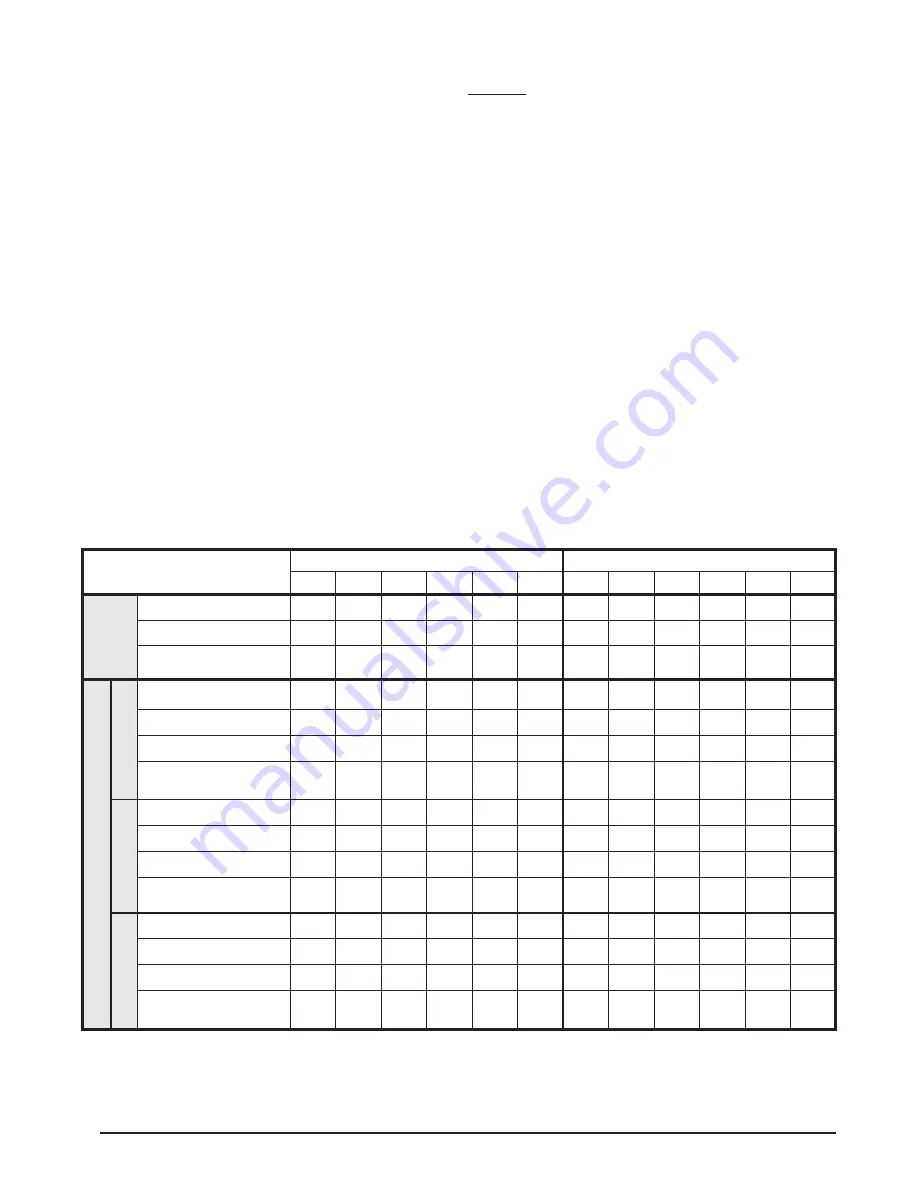

Table 2. Minimum Circuit Ampacity & Maximum Overcurrent Protection

Aux. Heat Installed

(Nom. KW)

Single Phase, 240 VAC, 50 & 60Hz

Single Phase, 208 VAC, 60Hz

NONE

005H

008H

010H

015H

020H

NONE

005H

008H

010H

015H

020H

Single Cir

cuit

***Min. Circuit Amp.

7.5

32.5

46.6

57.5

82.5

107.5

7.5

29.1

41.2

50.8

72.4

94.0

*Wire AWG 75

o

C

14

8

8(6**)

6

4(3**)

2

14

10(8**)

8

6

4

3

Maximum Over-current

Rating

15

40

50

60

90

125

15

30

50

60

80

100

Multiple Cir

cuit

Cir

cuit A

***Min. Circuit Amp.

7.5

32.5

46.6

57.5

57.5

57.5

7.5

29.1

41.2

50.8

50.8

50.8

*Wire AWG 60

o

C

14

8

6

4

4

4

14

10(8**)

6

6

6

6

*Wire AWG 75

o

C

14

8

8(6**)

6

6

6

14

10(8**)

8

6

6

6

Maximum Over-current

Rating

15

40

50

60

60

60

15

30

50

60

60

60

Cir

cuit B

***Min. Circuit Amp.

-

-

-

-

25.0

50.0

-

-

-

-

21.6

43.3

*Wire AWG 60

o

C

-

-

-

-

10

6

-

-

-

-

10

6

*Wire AWG 75

o

C

-

-

-

-

10

8

-

-

-

-

10

8

Maximum Over-current

Rating

-

-

-

-

30

60

-

-

-

-

25

50

Cir

cuit C

***Min. Circuit Amp.

-

-

-

-

-

-

-

-

-

-

-

-

*Wire AWG 60

o

C

-

-

-

-

-

-

-

-

-

-

-

-

*Wire AWG 75

o

C

-

-

-

-

-

-

-

-

-

-

-

-

Maximum Over-current

Rating

-

-

-

-

-

-

-

-

-

-

-

-

*All wire sizes for copper conductors only, based on NEC Table 310-16.

**Required for C-cabinet variable speed.

***Circuit ampacity slightly higher for variable speed. See label on blower.