6

All local codes having jurisdiction shall also

apply.

Air Duct Codes and Specifications

Air ducts must be installed in accordance with

National Fire Protection Association standards

NFPA 90A and NFPA 90B, these instructions,

and all applicable local codes.

• Materials: Air ducts must be aluminum, tin

plate, galvanized sheet steel, or other ap-

proved materials for outlet or return air ducts.

• Construction: Snap-Lock or Pittsburgh-Lock

seams are preferred. All other types of

seams must be made tight to prevent leak-

age.

• Sizing: Supply duct system must be designed

for proper air distribution. Static pressure

measured externally to furnace shall not ex-

ceed static pressure rating listed on furnace

nameplate.

• Location of Openings: Duct system must be

designed so that no supply registers are

located in duct system directly below furnace.

Return Air Codes and

Requirements

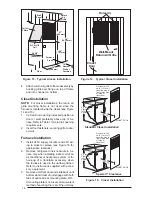

Non-ducted return air systems may be used for

closet or alcove installations.

NOTE: Applicable installation codes may limit

the furnace to installation in a single-story resi-

dence only. Furnace installations other than

closet or alcove installations require ducted

return air systems.

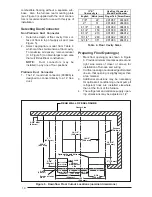

Air return to the furnace must have a minimum

free area opening (see Table 1).

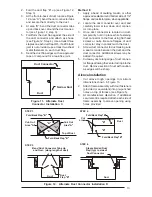

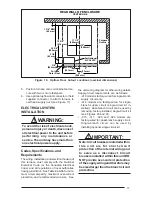

Acceptable floor or ceiling return air systems for

closet installations with return air entering

through an opening in the closet floor or ceiling

must meet all of the following requirements:

• Return air opening into closet, regardless of

its location, must not be smaller than size

specified on unit data label.

• If located in floor of closet, return air opening

must be provided with means of preventing

its inadvertent closure by a flat object placed

over opening.

• Materials located in return air duct system

must have a flame-spread classification of

200 or less.

• Noncombustible pans having 1" upturned

flanges must be located beneath openings in

a floor-return duct system.

• Wiring materials located in return duct sys-

tem must conform to NEC Article 300-22(c).

• Gas piping must not run in or through return

air duct system.

• If return air opening is located below top of

furnace, a minimum clearance must be pro-

vided between opening and furnace (see

“Accessibility for servicing” in Table 1).

Closed-Off Space Requirements

Living space not served by, and closed off from,

the return air ducts to the furnace by doors,

sliding partitions, and other means must be

provided with permanent, uncloseable open-

ings in the doors or partitions to allow air to

return to the furnace from all parts of the home.

Return air grilles, with a minimum open area of

one square inch for every five square feet of

living space closed off from the furnace, must be

provided in the door or room partition.

OPTIONAL EQUIPMENT

Contact your nearest NORDYNE distributor for

a complete list of electric furnace accessories.

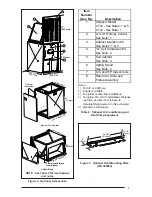

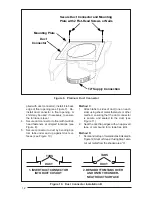

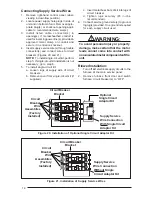

Return Air Grille

A return air grille and frame assembly (see

Figure 2) is available for use in non-ducted

return air installations. In downflow alcove in-

stallations, the grille and frame assembly may

be mounted directly to the top of the furnace. In

closet installations, a wall mount grille is avail-

able for attachment to a door or wall.

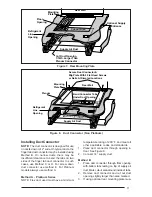

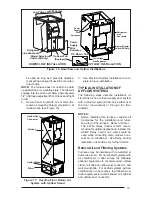

Optional Automatic Furnace

Damper #901083 -

Furnace may (not required) be equipped with

the optional automatic damper when a pack-

aged air conditioner is installed and connected

to the warm air duct system. This damper pre-

vents cooled air from discharging through the

furnace cabinet, causing excessive cooling of

the immediate area. Refer to instructions sup-

plied with the damper for details.

Multi-Speed Blower Conversion

Package (4 or 5 ton):

Upgrade blower packages are available for

adding air conditioning or heat pump systems.

See furnace “Options and Compatibility” label

for systems available.