BIM 1030/2005/03

10

www.nord.com

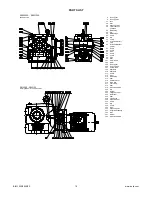

PARTS LIST

SK 02050 A - SK 42125 A

Shaft mounted

SK 13050 - SK 43125

Worm geared motor triple reduction

5

Driving gear

6

Driving pinion

27

Bolt

28

Seal

29

Supporting disc

30

Third reduction

gearcase

45

Ball bearing

46

Key

48

Ball bearings

52

Circlip

53

Key

54

Circlip

55

Intermediate shaft,

plain

56

Intermediate shaft,

gearcut

57

Circlip

58

Circlip

59

Shim

60

Circlip

61

Circlip

62

Plug

63

Seal

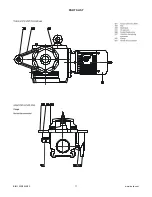

301

Worm wheel

302

Worm

305

Driving gear

306

Driving pinion

307

Hollow shaft

309

Shaft seal

310

Shaft seal

311

Circlip

312

Shim

313

Ball bearing

314

Seal

315

Gearcase cover

316

Drain plug

317

Vent screw

318

Seal

319

Socket head screw

320

Key

322

Spacer

323

Flanged eye bolt

324

Gear caser

325

Seal

328

Locking cap

329

Supporting disc

332

Circlip

333

Key

334

Circlip

335

Shim

336

Supporting disc

337

Angular ball bearing

340

Disc

341

Washer

342

Socket head screw

Содержание UNICASE Series

Страница 6: ...BIM 1030 2005 03 6 www nord com...

Страница 11: ...BIM 1030 2005 03 11 www nord com PARTS LIST...