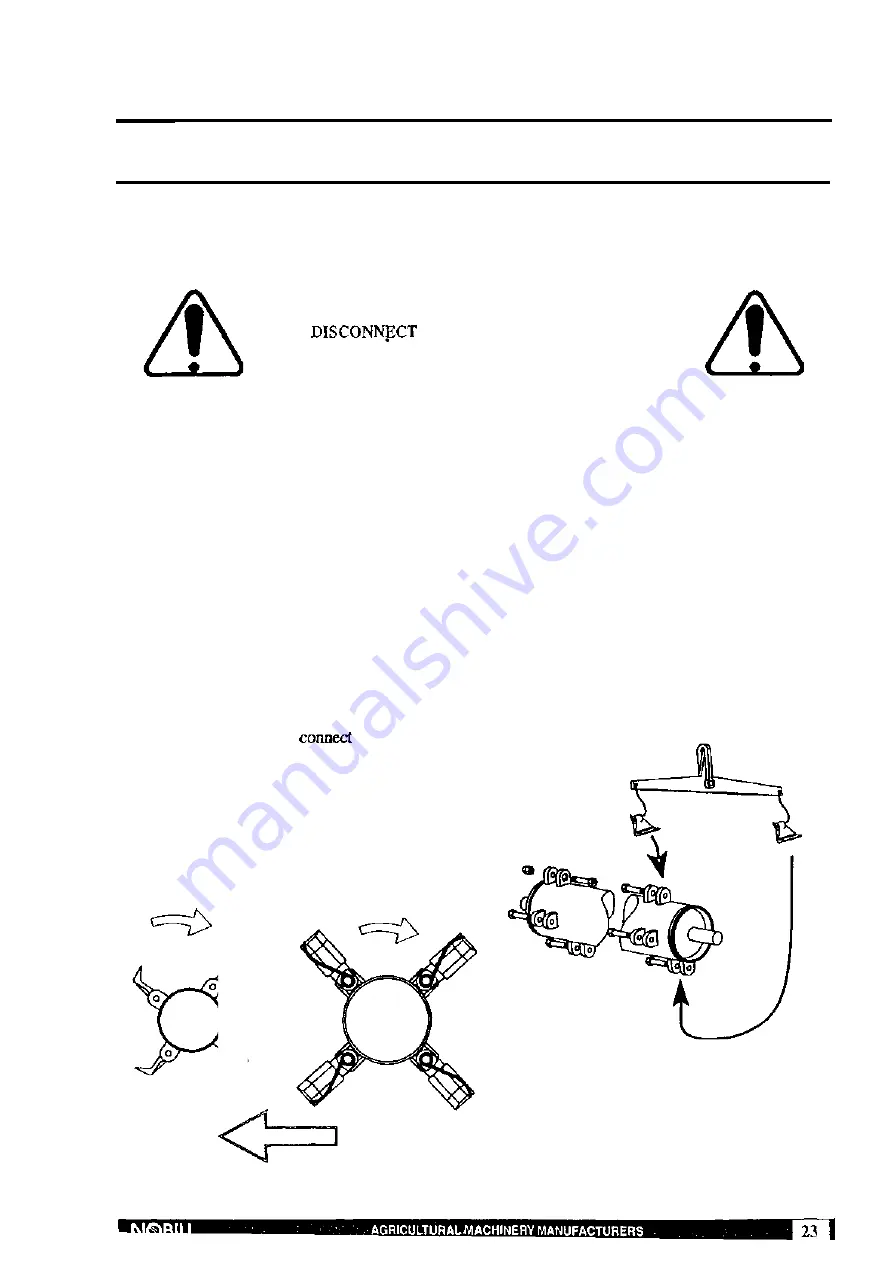

GENERAL INSTRUCTIONS

FOR BLADE

OR RAM REPLACEMENT

Every day check the condition of blades or

rams,

and corresponding locking pins.

In case

of

unusual wear or breaks, replace the parts immediately.

USE ORIGINAL SPARE PARTS ONLY.

BEFORE

REPLACING ANY PART,

THE MACHINE FROM THE

TRACTOR AND TILT IT FORWARD,

BY

RESTING

IT

ON

THE

COUPLING IF

THE

MACHINE IS

NOT

EQUIPPED WITH BONNET.

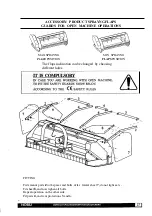

Partial replacement:

In addition to the worn-out, broken couple of blades

or

rams, replace the couple of blades

or

rams

diametricallyopposed,

so

as

to maintain the already existingbalancing.

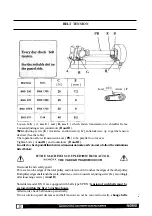

Total replacement:

Light differences in weight

of

the parts

are

acceptable.

Weigh blade

or

ram

units

singularly,

selecting

couples of same weight.

Those

couples shall be mounted on rotor

in

diametrically

opposed

positions.

REPLACE THE SELF-LOCKINGNUTS

IN

ANY CASE

Tighten

M

16

nuts with a

100

Nm

torque wrench setting.

Tighten

M

20 nuts with a 250

Nm

toque wrench setting..

When adjustment has

been

performed,

make

sure

axial

clearance

(

1-2

mm

)

between blades or

rams

and supports

is

still

allowed.

Thus,

to

check

balance,

the

tractor.

By

keeping the machine

raised

from

the

ground,

increase

P.T.O. speed

slowly

up

to get the

rated

speed.

If

repairhas

been

performed correctly, the machine will

run

at its

rated

speed without remarkable vibrations.

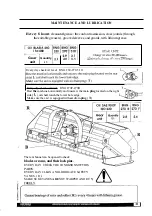

Rotor rotation Rotor

rotation

If the machine is equipped with

Y

blades

with

ventilating vanes, consider vane weight too.

If ventilating vanes are fitted,

make sure that

their assembly was performed correctly,

i.e.

correct direction.

(

See the drawing

).

Route of march