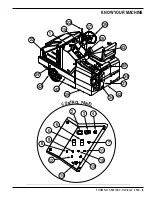

FORM NO. 56041389 - Retriever

™

4600 - 12

MAINTENANCE

To Adjust the Main Broom Height...

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

MAIN BROOM MAINTENANCE (CONTINUED)

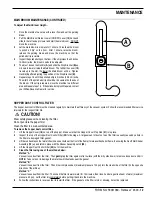

A

B

1

Drive the machine to an area with a level floor and set the parking

brake.

2

Pull the Main Broom Raise / Lower (ON/OFF) Lever (15) back and

slide to the left and up to lower and start the main broom. DO NOT

move the machine.

3

Let the main broom run in place for 1 minute. This allows the broom

to polish a “strip” on the floor. After 1 minute, raise the broom,

release the parking brake and move the machine so that the

polished strip is visible.

4

Inspect the polished strip on the floor. If the strip is less than 2 inches

(5.08 cm) wide, the broom needs to be adjusted.

5

To adjust, loosen the Handle (A) and slide the Stop Bracket (B) up

or down to lower or raise the Main Broom. The farther the Lever (15)

travels up in the slot, the lower the Main Broom will be. Tighten

Handle (A) after adjusting the position of the Stop Bracket (B).

6

Repeat steps 1-5 until the polished strip is 2 inches (5.08 cm) wide.

The width of the polished strip should be the same at both ends of

the broom. If the strip is tapered, move the machine to a different

area and repeat steps 1-5. If the polished strip is still tapered, contact

your Nilfisk-Advance Dealer for service.

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

HOPPER DUST CONTROL FILTER

The hopper dust control filter must be cleaned regularly to maintain the efficiency of the vacuum system. Follow the recommended filter service

intervals for the longest filter life.

CAUTION!

Wear safety glasses when cleaning the filter.

Do not puncture the paper filter.

Clean the filter in a well-ventilated area.

To remove the hopper dust control filter...

1

Lift the Hopper Cover (18) on top of the hopper. Make sure that the Hopper Cover Prop Rod (21) is in place.

2

Inspect the top of the Hopper Dust Control Filter (20) for damage. A large amount of dust on top of the filter is usually caused by a hole in

the filter or a damaged filter gasket.

3

Lift the red handles on the two latches (one on each side at the front of the frame) to release the shaker frame, then swing the Dust Filter Shaker

Assembly (19) up and latch in place with the Shaker Assembly Latch (38).

4

Lift the Hopper Dust Control Filter (20) out of the machine.

5

Clean the filter using one of the methods below:

Method “A”

Vacuum loose dust from the filter. Then gently tap the filter against a flat surface (with the dirty side down) to remove loose dust and dirt.

NOTE: Take care not to damage the metal lip which extends past the gasket.

Method “B”

Vacuum loose dust from the filter. Then blow compressed air (maximum pressure 100 psi) into the clean side of the filter (in the opposite

direction of the airflow).

Method “C”

Vacuum loose dust from the filter. Then soak the filter in warm water for 15 minutes, then rinse it under a gentle stream of water (maximum

pressure 40 psi). Let the filter dry completely before putting it back into the machine.

6

Follow the instructions in reverse order to install the filter. If the gasket on the filter is torn or missing, it must be replaced.