4.

Alignment and Measurement

Figure 4.3.: View of alignment window in collinear and non-collinear mode (visible laser used for

demonstration purpose).

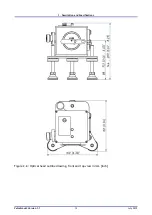

Figure 4.4.:

Pulse

Scout2

optical head right side view with beam distance screw

The beam distance, once the two re ections are aligned properly, can be changed to the collinear

mode in order to maximize the autocorrelation signal on the Control Software. The autocorrelation

signal will increase while changing from non-collinear to collinear mode.

If one has trouble nding the autocorrelation trace, turn the screw (see Figure 4.4) all the way in for

collinear operation (see Figure 4.3). In collinear mode, a signal increase from the autocorrelator

can be seen if the crystal is aligned at the proper angle, even if the two replica beams do not

overlap temporally. Hence, due to the fewer variables involved, it is best to use the collinear

con guration to begin with the optimization of the autocorrelation trace.

Once the optical assembly is coarsely aligned, it should be xed to the table with the provided foot

clamps.

Adjust the input beam in horizontal and vertical position in order to increase the autocorrelation

signal in comparison to the background signal. The variable alignment aperture can now be moved

into the measurement position (see Figure 4.2 on page 23).

Pulse

Scout2 Version 1.1

24

July 2015