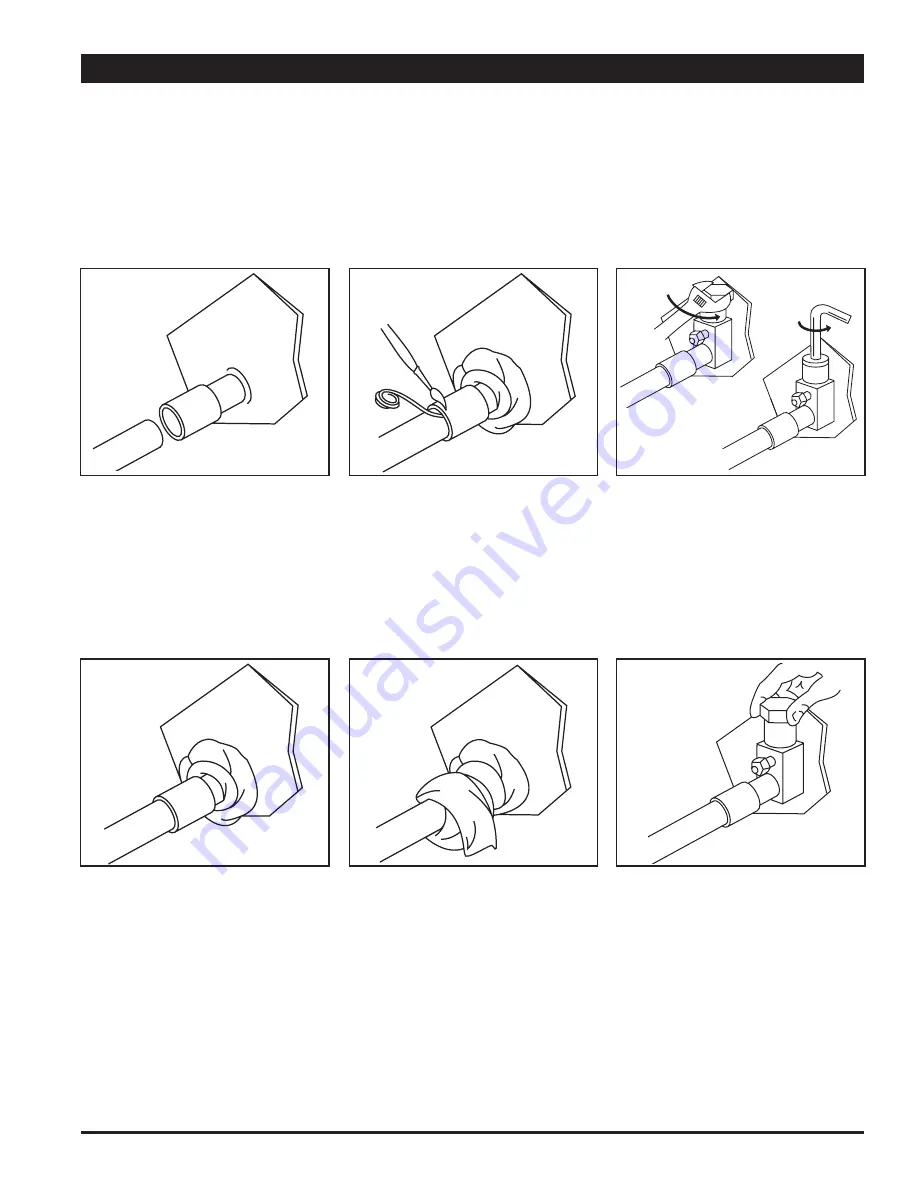

Figure 1 - Installing Refrigerant Lines

Field Installation:

Install the outdoor and indoor units

per the manufacturer’s recommendations.

Route the copper lines between the units.

3

Step 1:

The tubing should be cut

square. Make sure it is round

and free of burrs at the con-

necting ends. Clean the tub

-

ing to prevent contaminants

from entering the system.

Step 3:

Flux the copper tube and in

-

sert into the stub. Braze the

joint. No flux is necessary if a

low to zero-silver braze alloy

is used.

Step 5:

This is not a back seating

valve. To open the valve re-

move the valve cap with an

adjustable wrench. Insert a

3/16” or 5/16” hex wrench into

the stem. Back out counter-

clockwise until the valve stem

just touches the retaining

ring.

Step 2:

Wrap a wet rag around the

copper stub before brazing.

Step 4:

After brazing, quench with a

wet rag to cool the joint and

remove any flux residue.

Evacuate, purge or charge

the connecting lines per the

unit manufacturer’s instruc

-

tions.

Step 6:

Replace the valve cap finger

tight then tighten an addi

-

tional 1/12 turn or 1/2 hex flat.

A metal-to-metal seal is now

complete. Complete normal

factory recommended proce-

dures.

Содержание NCHP-018

Страница 7: ...Figure 2 Wiring Schematic Heat Pump Units NCHP 018 024 030 1019 3019 7 ...

Страница 15: ...SPLIT SYSTEM HEAT PUMP INSTALLATION INSTRUCTIONS Rev 09 09 ...

Страница 16: ......