5

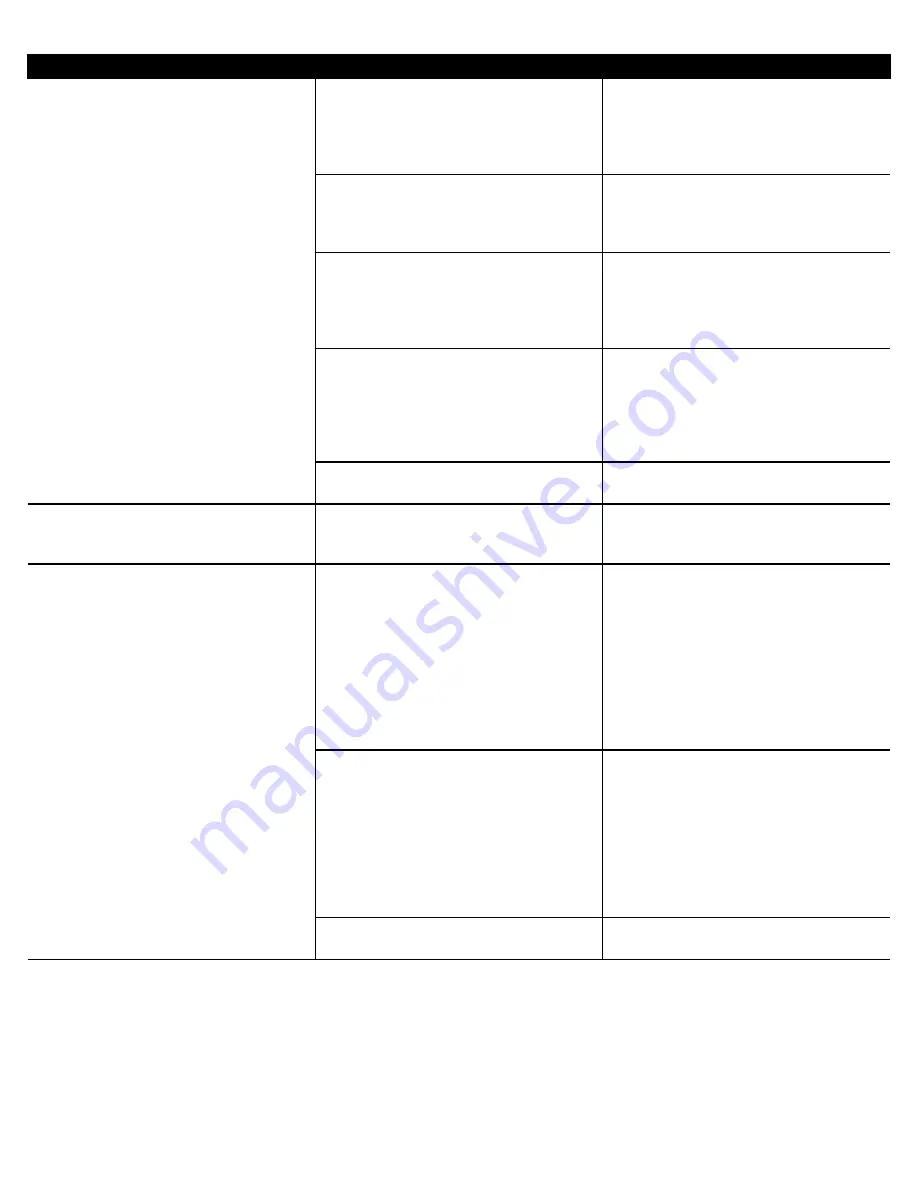

Condition/Problem

Things to Check

Solution

11.

Heart rate not displayed while using chest

strap (if equipped)

11.1

Transmitter not making good contact with

skin

Make sure heart rate monitor is under clothing,

against the skin, and as high under the pectoral

muscles as is comfortable. Use saline solution (sa-

liva or contact lens solution) to wet the electrode

areas on the sensor unit.

11.2

Electromagnetic interference

Turn off any television, AM radio, microwave, or

computer within 6 feet (2 meters) of the Mobia™

fitness machine. Try positioning the machine in

another area.

11.3

Chest strap transmitter

Test chest strap with another HR monitoring

device such as HR watch or a machine at a gym.

If transmitter has good skin contact and still is

not found to be emitting HR signal replace HR

TRANSMITTER.

11.4

HR receiver connection

If chest strap is known to work with other devices

and no sources of interference are present, or if

console has been tested with a Pulse Simulator

and is not receiving the signal, check HR receiver

connection at back of upper electronics board

(remove panel on underside of console for access).

11.5

Upper electronics

If above steps have not resolved issue replace

UPPER CONSOLE

12.

“Tick” sound once per revolution or scraping

noise from under treadle

12.1

Belt alignment

Belt seam may be contacting metal belt guide

under treadle. Slight adjustment of belt should

alleviate noise.

13.

Treadles don’t operate as expected

13.1

Customer perception

Some new owners may not realize that the

Treadles do not move up and down on their own.

Make sure that the customer understands that the

Treadle movement is generated by their walking

motion. Also make sure that they understand the

Treadles will not normally go through their full

range of motion as would a stepper; the Treadles

usually move only a few inches to cushion each

footstep. Customers should walk normally and not

try to force Treadle movement.

13.2

Hydraulic shocks

If customer feels that resistance is uneven from

one Treadle to the other, first start off with the in

-

tensity setting equal on each hydraulic. The white

dial indicator triangle on each hydraulic shock

should also be facing towards the user when they

are on the machine. Adjust one shock only in small

increments until Treadle travel matches. A higher

setting increases travel, while a lower setting

reduces it.

13.3

Treadle binding

If Treadles are “hanging up” as they pass each

other then replace friction block.