- 10 -

GAS FORGE H3

WARNING:

To proceed with the maintenance of the oven it is necessary to turn off the

Burners

and wait 24 hours to

ensure that all the components are at ambient temperature.

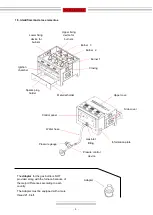

3. MAINTENANCE

3.1. General Maintenance

- It is recommended to keep the

Combustion chamber

clean, as far as possible, to ensure proper operation

and thus prolong the useful life of the insulating material.

- It is recommended to check the status of the thermocouple, the ignition device, the gas valve, the regulator

and the non-return valve. If any of these elements suffers any type of deterioration, contact the Nargesa

technical service.

- It is required the replacement of the thermocouple, the ignition device, the gas valve, the regulator and the

non-return valve every 5 years. It is advisable that the technical service of Nargesa make this substitution.

- It is recommended to check periodically the condition of the isolating material to ensure good insulation of

the

Combustion chamber

with the outside of the oven. In case the isolating material is degraded, it can be

damaged immediately and irreparable damage will be caused to the metallic enclosure.

- It is recommended to replace the insulating material every 1000 hours of operation.

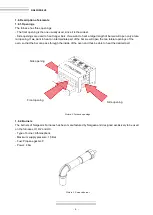

Picture 7. Insolating kit

Содержание H3

Страница 2: ...Thank you for choosing our machines www nargesa com...

Страница 26: ...Tecnichal Annex Furnace H3 List of parts Gas layout...

Страница 27: ...A3 List of parts...

Страница 28: ...A4 GAS FORGE H3...

Страница 29: ...A5...

Страница 30: ...A6 GAS FORGE H3...

Страница 31: ...A7...

Страница 32: ...A8 GAS FORGE H3...

Страница 33: ...A9 Gas layout...