EN

W415-4020 / 08.09.21

67

troubleshooting

!

WARNING

• Always light the pilot whether for the fi rst time or if the gas supply has run out, with the glass door open or

removed.

• Turn off gas and electrical power before servicing the appliance.

• Appliance may be hot. Do not service until appliance has cooled.

• Do not use abrasive cleaners

27.1A

symptom

problem

test solution

Main burner fl ame is a

blue, lazy, transparent

fl ame.

(This is not applicable

in outdoor appliances)

Blockage in vent.

-

Remove blockage. In really cold conditions, ice buildup may occur

on the terminal and should be removed as required. (To minimize this

from reoccuring, the vent lengths that pass through unheated spaces

(attics, garages, crawl spaces) should be wrapped with an insulated

mylar sleeve).

Incorrect installation.

-

Refer to “venting” section to ensure correct installation.

Flames are consistently

too large or too small.

Carboning occurs.

Appliance is over-fi red or under-

fi red.

-

Check pressure readings:

Inlet pressure can be checked by turning screw (A) counter-clock-

wise 2 or 3 turns and then placing pressure gauge tubing over the

test point. Gauge should read as described on the chart below.

Check that main burner is operating on ‘HI’. Outlet pressure can be

checked the same as above using screw (B). Gauge should read as

described on the chart below. Check that main burner is operating

on ‘HI’.

After taking pressure readings, be sure to turn screws

clockwise fi rmly to reseal. DO NOT OVER TORQUE.

Leak test with a soap and water solution.

Air shutter improperly adjusted.

-

Return air shutter to specifi ed opening, see “

venturi adjustments

”

section in the installation manual.

Carbon is being

deposited on glass,

logs, rocks, media, or

combustion chamber

surfaces.

Air shutter is blocked.

-

Ensure air shutter opening is free of lint or other obstructions.

Flame is impinging on the glass,

logs, rocks, media or combus-

tion chamber.

-

Ensure the media is positioned correctly in the appliance.

-

Open air shutter to increase the primary air.

-

Check the input rate: check the manifold pressure and orifi ce size as

specifi ed by the rating plate.

-

Ensure door gaskets are not broken or missing and the seal is tight.

-

Ensure vent liners are free of holes and well sealed at all joints.

-

Check that minimum rise per foot (meters) has been adhered to for

any horizontal venting.

White / grey fi lm forms.

Sulphur from fuel is being depos-

ited on glass, logs, or combus-

tion chamber surfaces.

-

Clean the glass with a recommended gas fi replace glass cleaner.

DO

NOT CLEAN GLASS WHEN HOT.

-

If deposits are not cleaned off regularly, the glass may become

permanently marked.

Exhaust fumes smelled

in room, headaches.

Appliance is spilling.

(This is not applicable in outdoor

appliances).

-

Check door seal.

-

Check for exhaust damage.

-

Check that venting is installed correctly.

-

Room is in negative pressure; increase fresh air supply.

INSERT

PHOTO

OF VALVE

HERE

symptom

problem

test solution

Pilot will not light. Makes

noise with no spark at

pilot burner.

Wiring: short, loose, or damaged

connections

(poor fl ame rectifi cation).

-

Verify the thermocouple/sensor is clean and the wiring is undamaged.

-

Verify the interrupter block is not damaged or too tight. Verify

connections from pilot assembly are tight; also verify the connections

are not grounding out to any metal. (Remember, the fl ame carries the

rectifi cation current, not the gas. If fl ame lifts from pilot hood, the circuit

is broken. A wrong orifi ce or too high of an inlet pressure can cause the

pilot fl ame to lift)*. The sensor rod may need cleaning.

No signal from remote with no

pilot ignition.

-

Reprogram receiver code.

-

Replace receiver.

Poor grounding.

-

Verify the valve / pilot assembly are properly grounded

Improper switch wiring.

-

Troubleshoot the system with the simplest

on/off

switch.

Dirty, painted, or damaged pilot

and/or dirty sensor rod.

-

Clean sensor rod with a green Scotch-Brite™ pad to remove any

contamination that may have accumulated. Verify continuity with

multimeter with ohms set at the lowest range.

Pilot sparks but will

not light.

Gas supply.

- Verify that the incoming gas line ball valve is “open”.

- Verify that the inlet pressure reading is within acceptable

limits, inlet pressures must not exceed 13” W.C. (32.4mb).

Out of propane gas.

- Fill the tank.

Pilot supply line may contain

air.

- Repeat ignition process several times or purge the pilot

supply line.

Incorrect wiring / grounding.

- Ensure correct polarity of wiring of thermocouple (if

equipped).

- Verify pilot assembly / valve are properly grounded.

Receiver (if equipped).

- Reset program: hold reset button on receiver and wait for 2

beeps. Release after second beep. Press small fl ame button

on remote within 20 seconds, you will hear an additional

beep (this signals a successful reset).

- Replace receiver.

Valve.

- Check valve and replace if necessary (Do not to overtighten

thermocouple).

Burner continues to

spark and pilot lights

but main burner

does not light.

Short or loose connection in

sensor rod.

- Verify all connections. Verify the connections from the pilot

assembly are tight. Also, verify these connections are not

grounding out to any metal.

Dirty, painted, or damaged

pilot assembly components.

- Clean using a green Scotch-Brite™ pad to remove any

contamination that may have accumulated on the sensor

rod, pilot hood, ignitor, or fl ame sensor. Verify continuity with

multimeter with ohms set at the lowest range.

Remote wall switch

is in “

off

” position;

burner comes on.

Wall switch mounted upside

down.

- Reverse.

Remote wall switch and/or

wire is grounding.

- Replace.

- Check for ground (short); repair ground or replace wire.

Faulty wire

- Replace.

Remote and / or

receiver is not

functioning properly.

Remote controls lights but

no spark or fl ame. (Remote is

locked out).

-

Reset by turning power source off then on.

Receiver or remote has low battery.

-

Replace batteries.

Appliance functions but does not

respond to receiver / remote

-

Ensure appliance is being operated by the same device that turned it

on. Remote controls function if appliance was turned on by remote.

Receiver controls function if appliance was turned on by receiver.

Error with synchronizing.

-

Reset receiver and remote.

Remote too far away from receiver.

-

Refer to “wiring diagram” section.

Wire connector pins are bent.

-

Straighten pins.

Valve wiring is damaged.

-

Replace valve.

symptom

problem

test solution

The following applies specifi cally to the SIT system only:

Pilot will not light.

Makes no noise with

no spark at pilot

burner. (Lights and

blower operate, if

equipped).

Ignition box has been locked

out.

Choose one of the 3 methods below to reset the system.

1.

To reset ignition box when locked out. Turn off power supply

and remove batteries (if used) from the back up battery pack.

2.

To reset the DFC Board when the board goes into a lock

out condition and the LED is blinking 3 times using the

transmitter

on/off

button:

Step 1:

Turn the system off by pressing the

on/off

button to turn the system off.

Step 2:

After approximately 2 seconds press the

on/

off

button on the transmitter again. The DFC Board will

reset and the ignition sequence will start again.

3.

To reset the DFC Board when the board goes into a lock out

condition and the LED is blinking 3 times by cycling fl ame:

Step 1:

In the manual fl ame control mode, use the down

arrow button to reduce the fl ame to off, indicated by the

word OFF displayed on the transmitter LCD screen.

Step 2:

Wait approximately 2 seconds and press the up

arrow button, the ignition sequence will start.

symptom

problem

test solution

The following applies specifi cally to the Maxitrol system only:

Pilot lights.

No gas fl ow.

Manual override knob is in the

“MAN” position.

-

Turn the knob to the “ON” position.

Valve is not functioning properly.

-

Valve is on pilot fl ow. Turn to the high setting, double click the large

fl ame button on the remote.

-

Replace valve. Do not overtighten.

No spark after pilot

ignition. Valve turns off

in one minute and does

not operate.

Minimal voltage from thermocou-

ple or resistance in circuit ports

(Parts include: “ON/OFF” switch,

receiver, thermocurrent connec-

tions or temperature switches).

-

Measure the voltage, it should read a least 5mV. The spade

connector is on the outer surface beside the magnet nut. Verify with

manufacturer the drop time, after thermocouple is heated measure

the drop time.

No pilot ignition

(5 second continuous

beep).

Switch is in “OFF” position on

the valve.

-

Switch to “ON“ position.

Wiring is loose.

-

Ensure wiring is properly secured.

Receiver (if equipped).

-

Reset program: hold reset button on receiver and wait for 2 beeps.

Release after second beep. Press small fl ame button on remote

within 20 seconds, you will hear an additional beep (this signals a

successful reset).

-

Replace receiver.

Wire connector pins are bent.

-

Straighten pins.

Valve wiring is damaged.

-

Replace valve.

Burner continues to

spark and pilot lights

but main burner does

not light.

Connections are loose or dam-

aged.

-

Verify the thermocouple is clean and the wiring between it and the

valve is undamaged.

-

Verify the interrupter block is not damaged or too tight.

Remote and / or re-

ceiver is not function-

ing properly.

Receiver not communicating

properly.

-

Hold reset button on the receiver and wait for 2 beeps. Release after

second beep. Press the small fl ame button on the remote within

20 seconds, you will hear an additional beep (this signals that the

receiver has been successfully reset).

Motor is turning,

frequent beeping

occurs.

Receiver batteries low.

- Replace batteries.

*Maximum inlet pressure not to exceed 13” w.c.

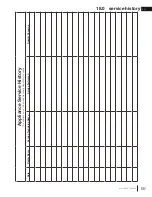

Pressure

Natural Gas

(inches)

Natural Gas

(millibars)

Propane

(inches)

Propane

(millibars)

Inlet

*7”

(minimum 4.5”)

17.4mb

(minimum 11.2mb)

13”

(minimum 11”)

32.4mb

(minimum 27.4mb)

Outlet

3.5”

8.7mb

10”

24.9mb

If back up batteries are installed, they must also be removed to

re-program

note:

Starting from

off

, press the

on

button on the transmitter. After approximately 4 seconds

on/off

button is pressed, the ignition

board will start the spark. The atempt for ignition will last approximately 60 seconds. If there is no fl ame ignition (rectifi cation),

the board will stop sparking and the board will go into lock out.

note:

symptom

problem

test solution

Lights or blower

won’t function (if

equipped).

Control module switch in

wrong position.

- Verify ON/OFF switch is in the “I” position which denotes on.

COM switch is unplugged.

- Verify “COM” switch is plugged into the front of the control

module.

Flames are very

aggressive.

Door is ajar.

- Ensure door is secured properly.

Venting action is too great.

- Check to ensure venting is properly sealed or restrict vent

exit with restrictor plate. (Not available in all appliances).

Appliance won’t per-

form any functions.

No power to the system.

- Check breaker to verify it’s in the “

on

” position.

Receiver switch in wrong

position (if equipped).

- Verify that the 3 position switch on the receiver is in the

remote position (middle).

Transmitter isn’t operational.

- Check battery power and battery orientation.

!

WARNING

• Always light the pilot whether for the fi rst time or if the gas supply has run out, with the glass door open or

removed.

• Turn off gas and electrical power before servicing the appliance.

• Appliance may be hot. Do not service until appliance has cooled.

• Do not use abrasive cleaners

27.1A

symptom

problem

test solution

Main burner fl ame is a

blue, lazy, transparent

fl ame.

(This is not applicable

in outdoor appliances)

Blockage in vent.

-

Remove blockage. In really cold conditions, ice buildup may occur

on the terminal and should be removed as required. (To minimize this

from reoccuring, the vent lengths that pass through unheated spaces

(attics, garages, crawl spaces) should be wrapped with an insulated

mylar sleeve).

Incorrect installation.

-

Refer to “venting” section to ensure correct installation.

Flames are consistently

too large or too small.

Carboning occurs.

Appliance is over-fi red or under-

fi red.

-

Check pressure readings:

Inlet pressure can be checked by turning screw (A) counter-clock-

wise 2 or 3 turns and then placing pressure gauge tubing over the

test point. Gauge should read as described on the chart below.

Check that main burner is operating on ‘HI’. Outlet pressure can be

checked the same as above using screw (B). Gauge should read as

described on the chart below. Check that main burner is operating

on ‘HI’.

After taking pressure readings, be sure to turn screws

clockwise fi rmly to reseal. DO NOT OVER TORQUE.

Leak test with a soap and water solution.

Air shutter improperly adjusted.

-

Return air shutter to specifi ed opening, see “

venturi adjustments

”

section in the installation manual.

Carbon is being

deposited on glass,

logs, rocks, media, or

combustion chamber

surfaces.

Air shutter is blocked.

-

Ensure air shutter opening is free of lint or other obstructions.

Flame is impinging on the glass,

logs, rocks, media or combus-

tion chamber.

-

Ensure the media is positioned correctly in the appliance.

-

Open air shutter to increase the primary air.

-

Check the input rate: check the manifold pressure and orifi ce size as

specifi ed by the rating plate.

-

Ensure door gaskets are not broken or missing and the seal is tight.

-

Ensure vent liners are free of holes and well sealed at all joints.

-

Check that minimum rise per foot (meters) has been adhered to for

any horizontal venting.

White / grey fi lm forms.

Sulphur from fuel is being depos-

ited on glass, logs, or combus-

tion chamber surfaces.

-

Clean the glass with a recommended gas fi replace glass cleaner.

DO

NOT CLEAN GLASS WHEN HOT.

-

If deposits are not cleaned off regularly, the glass may become

permanently marked.

Exhaust fumes smelled

in room, headaches.

Appliance is spilling.

(This is not applicable in outdoor

appliances).

-

Check door seal.

-

Check for exhaust damage.

-

Check that venting is installed correctly.

-

Room is in negative pressure; increase fresh air supply.

INSERT

PHOTO

OF VALVE

HERE

symptom

problem

test solution

Pilot will not light. Makes

noise with no spark at

pilot burner.

Wiring: short, loose, or damaged

connections

(poor fl ame rectifi cation).

-

Verify the thermocouple/sensor is clean and the wiring is undamaged.

-

Verify the interrupter block is not damaged or too tight. Verify

connections from pilot assembly are tight; also verify the connections

are not grounding out to any metal. (Remember, the fl ame carries the

rectifi cation current, not the gas. If fl ame lifts from pilot hood, the circuit

is broken. A wrong orifi ce or too high of an inlet pressure can cause the

pilot fl ame to lift)*. The sensor rod may need cleaning.

No signal from remote with no

pilot ignition.

-

Reprogram receiver code.

-

Replace receiver.

Poor grounding.

-

Verify the valve / pilot assembly are properly grounded

Improper switch wiring.

-

Troubleshoot the system with the simplest

on/off

switch.

Dirty, painted, or damaged pilot

and/or dirty sensor rod.

-

Clean sensor rod with a green Scotch-Brite™ pad to remove any

contamination that may have accumulated. Verify continuity with

multimeter with ohms set at the lowest range.

Pilot sparks but will

not light.

Gas supply.

- Verify that the incoming gas line ball valve is “open”.

- Verify that the inlet pressure reading is within acceptable

limits, inlet pressures must not exceed 13” W.C. (32.4mb).

Out of propane gas.

- Fill the tank.

Pilot supply line may contain

air.

- Repeat ignition process several times or purge the pilot

supply line.

Incorrect wiring / grounding.

- Ensure correct polarity of wiring of thermocouple (if

equipped).

- Verify pilot assembly / valve are properly grounded.

Receiver (if equipped).

- Reset program: hold reset button on receiver and wait for 2

beeps. Release after second beep. Press small fl ame button

on remote within 20 seconds, you will hear an additional

beep (this signals a successful reset).

- Replace receiver.

Valve.

- Check valve and replace if necessary (Do not to overtighten

thermocouple).

Burner continues to

spark and pilot lights

but main burner

does not light.

Short or loose connection in

sensor rod.

- Verify all connections. Verify the connections from the pilot

assembly are tight. Also, verify these connections are not

grounding out to any metal.

Dirty, painted, or damaged

pilot assembly components.

- Clean using a green Scotch-Brite™ pad to remove any

contamination that may have accumulated on the sensor

rod, pilot hood, ignitor, or fl ame sensor. Verify continuity with

multimeter with ohms set at the lowest range.

Remote wall switch

is in “

off

” position;

burner comes on.

Wall switch mounted upside

down.

- Reverse.

Remote wall switch and/or

wire is grounding.

- Replace.

- Check for ground (short); repair ground or replace wire.

Faulty wire

- Replace.

Remote and / or

receiver is not

functioning properly.

Remote controls lights but

no spark or fl ame. (Remote is

locked out).

-

Reset by turning power source off then on.

Receiver or remote has low battery.

-

Replace batteries.

Appliance functions but does not

respond to receiver / remote

-

Ensure appliance is being operated by the same device that turned it

on. Remote controls function if appliance was turned on by remote.

Receiver controls function if appliance was turned on by receiver.

Error with synchronizing.

-

Reset receiver and remote.

Remote too far away from receiver.

-

Refer to “wiring diagram” section.

Wire connector pins are bent.

-

Straighten pins.

Valve wiring is damaged.

-

Replace valve.

symptom

problem

test solution

The following applies specifi cally to the SIT system only:

Pilot will not light.

Makes no noise with

no spark at pilot

burner. (Lights and

blower operate, if

equipped).

Ignition box has been locked

out.

Choose one of the 3 methods below to reset the system.

1.

To reset ignition box when locked out. Turn off power supply

and remove batteries (if used) from the back up battery pack.

2.

To reset the DFC Board when the board goes into a lock

out condition and the LED is blinking 3 times using the

transmitter

on/off

button:

Step 1:

Turn the system off by pressing the

on/off

button to turn the system off.

Step 2:

After approximately 2 seconds press the

on/

off

button on the transmitter again. The DFC Board will

reset and the ignition sequence will start again.

3.

To reset the DFC Board when the board goes into a lock out

condition and the LED is blinking 3 times by cycling fl ame:

Step 1:

In the manual fl ame control mode, use the down

arrow button to reduce the fl ame to off, indicated by the

word OFF displayed on the transmitter LCD screen.

Step 2:

Wait approximately 2 seconds and press the up

arrow button, the ignition sequence will start.

symptom

problem

test solution

The following applies specifi cally to the Maxitrol system only:

Pilot lights.

No gas fl ow.

Manual override knob is in the

“MAN” position.

-

Turn the knob to the “ON” position.

Valve is not functioning properly.

-

Valve is on pilot fl ow. Turn to the high setting, double click the large

fl ame button on the remote.

-

Replace valve. Do not overtighten.

No spark after pilot

ignition. Valve turns off

in one minute and does

not operate.

Minimal voltage from thermocou-

ple or resistance in circuit ports

(Parts include: “ON/OFF” switch,

receiver, thermocurrent connec-

tions or temperature switches).

-

Measure the voltage, it should read a least 5mV. The spade

connector is on the outer surface beside the magnet nut. Verify with

manufacturer the drop time, after thermocouple is heated measure

the drop time.

No pilot ignition

(5 second continuous

beep).

Switch is in “OFF” position on

the valve.

-

Switch to “ON“ position.

Wiring is loose.

-

Ensure wiring is properly secured.

Receiver (if equipped).

-

Reset program: hold reset button on receiver and wait for 2 beeps.

Release after second beep. Press small fl ame button on remote

within 20 seconds, you will hear an additional beep (this signals a

successful reset).

-

Replace receiver.

Wire connector pins are bent.

-

Straighten pins.

Valve wiring is damaged.

-

Replace valve.

Burner continues to

spark and pilot lights

but main burner does

not light.

Connections are loose or dam-

aged.

-

Verify the thermocouple is clean and the wiring between it and the

valve is undamaged.

-

Verify the interrupter block is not damaged or too tight.

Remote and / or re-

ceiver is not function-

ing properly.

Receiver not communicating

properly.

-

Hold reset button on the receiver and wait for 2 beeps. Release after

second beep. Press the small fl ame button on the remote within

20 seconds, you will hear an additional beep (this signals that the

receiver has been successfully reset).

Motor is turning,

frequent beeping

occurs.

Receiver batteries low.

- Replace batteries.

*Maximum inlet pressure not to exceed 13” w.c.

Pressure

Natural Gas

(inches)

Natural Gas

(millibars)

Propane

(inches)

Propane

(millibars)

Inlet

*7”

(minimum 4.5”)

17.4mb

(minimum 11.2mb)

13”

(minimum 11”)

32.4mb

(minimum 27.4mb)

Outlet

3.5”

8.7mb

10”

24.9mb

If back up batteries are installed, they must also be removed to

re-program

note:

Starting from

off

, press the

on

button on the transmitter. After approximately 4 seconds

on/off

button is pressed, the ignition

board will start the spark. The atempt for ignition will last approximately 60 seconds. If there is no fl ame ignition (rectifi cation),

the board will stop sparking and the board will go into lock out.

note:

symptom

problem

test solution

Lights or blower

won’t function (if

equipped).

Control module switch in

wrong position.

- Verify ON/OFF switch is in the “I” position which denotes on.

COM switch is unplugged.

- Verify “COM” switch is plugged into the front of the control

module.

Flames are very

aggressive.

Door is ajar.

- Ensure door is secured properly.

Venting action is too great.

- Check to ensure venting is properly sealed or restrict vent

exit with restrictor plate. (Not available in all appliances).

Appliance won’t per-

form any functions.

No power to the system.

- Check breaker to verify it’s in the “

on

” position.

Receiver switch in wrong

position (if equipped).

- Verify that the 3 position switch on the receiver is in the

remote position (middle).

Transmitter isn’t operational.

- Check battery power and battery orientation.