14

WWW

.N

AKAYAMA

T

OOLS

.

COM

The following maintenance intervals apply to

normal operating conditions only. If your

daily working time is longer than normal or

operating conditions are difficult (very dusty

work area etc.), shorten the specified

intervals accordingly.

befo

re

st

ar

tin

g wo

rk

aft

er

fi

ni

sh

in

g wo

rk

or

d

ai

ly

aft

er

ea

ch

re

fu

el

in

g

st

op

week

ly

m

ont

hl

y

ev

er

y 1

2 mo

nt

hs

I

f p

ro

bl

em

if d

ama

ged

if r

eq

ui

red

Complete machine

Visual

inspection

(condition,

leaks)

x

x

Clean

x

Control handle

Check

operation

x

x

Air filter

Clean

x

Replace

Filter in fuel tank

Check

x

Replace

x

x

fuel tank

Clean

x

Carburetor

Check idle

setting

x

x

Readjust idle

x

Spark plug

Readjust

electrode gap

x

Cooling air intakes

Clean

x

Spark arresting screen in

muffler

Check

x

Clean or

replace

x

All accessible screws and nuts

(not adjusting screws)

Tighten

x

Container with hose

Visual

inspection

(condition,

leaks)

x

Metering unit

Check

x

Anti-vibration elements

Visual

inspection

x

Have replaced

by dealer

x

Содержание BL4300

Страница 1: ...BL4300 Owner s manual Art Nr 023456 WWW NAKAYAMATOOLS COM...

Страница 2: ...2 WWW NAKAYAMATOOLS COM GR 1 2...

Страница 3: ...3 WWW NAKAYAMATOOLS COM...

Страница 4: ...4 WWW NAKAYAMATOOLS COM OFF 3 10...

Страница 5: ...5 WWW NAKAYAMATOOLS COM Service OFF ON...

Страница 6: ...6 WWW NAKAYAMATOOLS COM 90 Premium...

Страница 7: ...7 WWW NAKAYAMATOOLS COM TC H 1 2 TC 25 1...

Страница 8: ...8 WWW NAKAYAMATOOLS COM 1 ON 2...

Страница 9: ...9 WWW NAKAYAMATOOLS COM 2 1 OFF OFF ON 5 15...

Страница 10: ...10 WWW NAKAYAMATOOLS COM 1 2 H L 1 4 H L LA L LA...

Страница 11: ...11 WWW NAKAYAMATOOLS COM LA L H H 1 4 A 100 1 2 3 Service...

Страница 12: ...12 WWW NAKAYAMATOOLS COM 1 2 3 4 5 6 7 5 4 3...

Страница 13: ...13 WWW NAKAYAMATOOLS COM OFF 3 UV 43cc 1 7hp 12m3 min 4200m3 min 1 2L Service...

Страница 14: ...14 WWW NAKAYAMATOOLS COM 12 x x x x x x x x x x x x x x x x x x x x x Service x...

Страница 15: ...15 WWW NAKAYAMATOOLS COM Service...

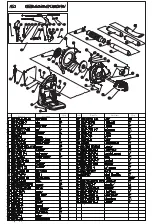

Страница 30: ...Ser No Part No Part Name Qty Ser No Part No Part Name Qty...

Страница 31: ...Ser No Part No Part Name Qty Ser No Part No Part Name Qty...