GM Series

TM19040 P.16/31

Step 4

Align (3) mounting bolt hole for equipment of GM with the mounting holes of the machinery, and

assemble GM into the machinery.

NOTICE

During the installation, do not hit GM with a hammer and the like.

Step 5

Insert the flat washers and the mounting bolts into (3) mounting bolt hole for equipment of GM.

NOTICE

Use the specified number of GM mounting bolts and tighten with the specified tightening torque.

Otherwise, not only GM may not provide its performance but also the customer machine and GM

may be damaged.

Step 6

Tighten the mounting bolts for equipment uniformly with the specified tightening torque. Refer to

the confirmation notice for the quantity and bolt size.

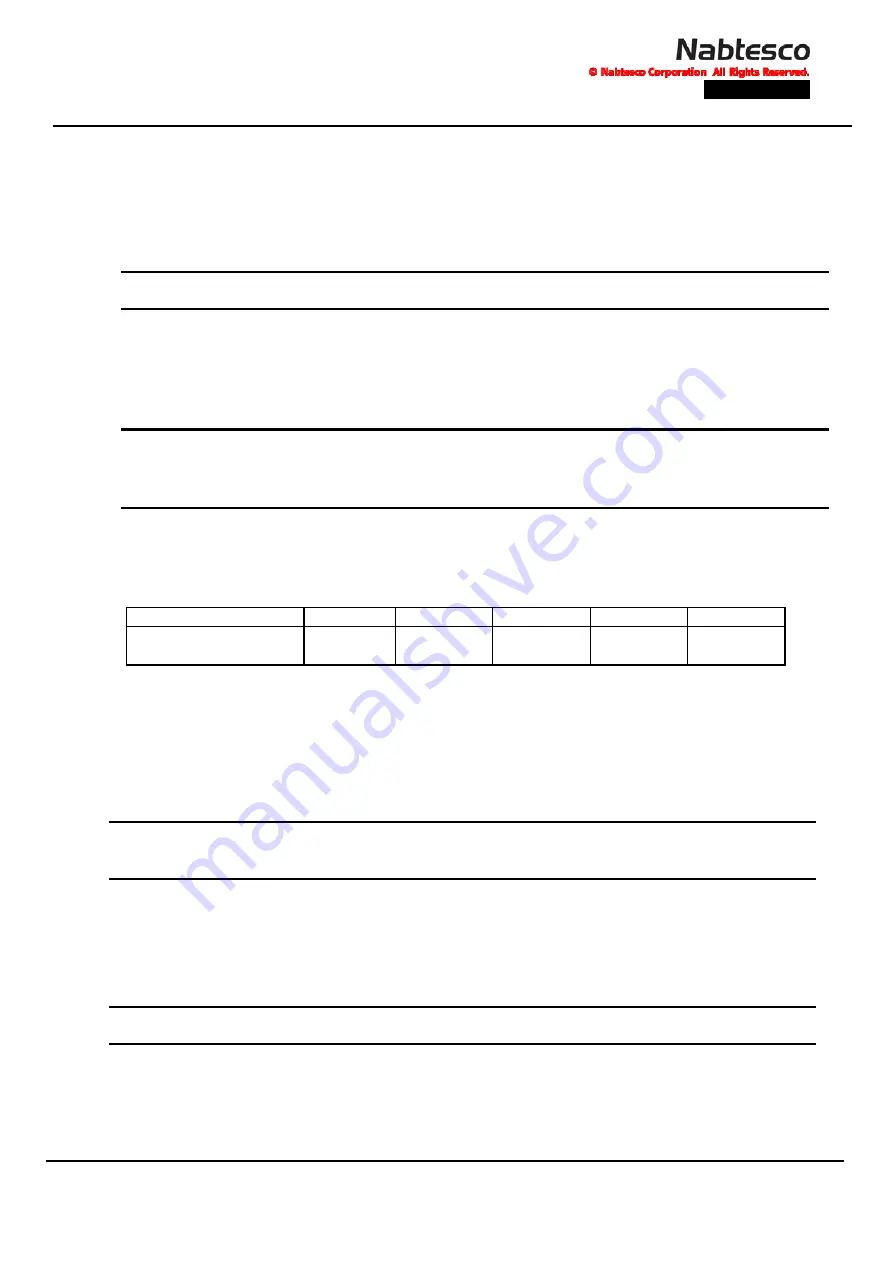

Table 4-1

Bolt tightening torque

Bolt size

M12(P1.75)

M14(P2.0)

M16(P2.0)

M20

(

P2.5)

M24

(

P3.0)

Tightening torque [N-m]

(

Recommendation

)

102±15.7

163±24.5

252±39.2

493±78.5

709±88.3

Step 7

Check that there are no burrs or dirt on (4) mounting surface for driving part of GM and GM

mounting surface of the driving part, and wipe off the antirust oil on (4) mounting surface for

driving part of GM and (5) bearing surface of the driving part.

NOTE

GM has antirust oil applied to the non-painted surfaces before shipping. To keep the transmitting

torque by bolts high, wipe off the antirust oil on the mounting surface sufficiently.

Step 8

Align (6) mounting bolt hole for driving part of GM with the mounting holes of the driving part,

and assemble the driving part into GM.

NOTICE

Please do not hit GM with a hammer or the like at the time of mounting.

Step 9

Insert the flat washers and the mounting bolt for driving part into (6) mounting bolt hole for

driving part of GM.