VJ-2606 INSTALLATION MANUAL

VJ2606E-I-01

6

1

2

4

3

2

1

1

1

1

(Cont'd)

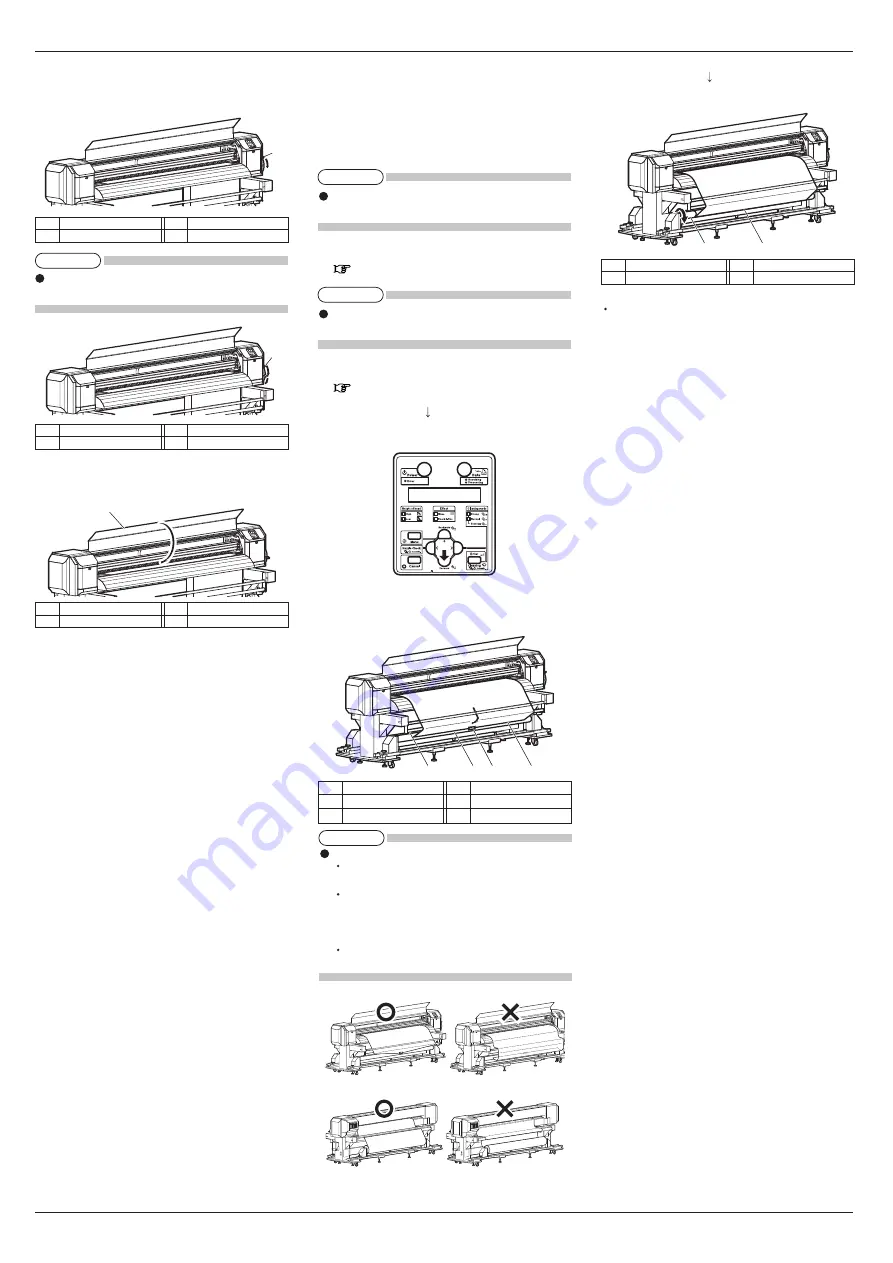

17. Lower the media loading lever.

When you increase the pressure for the media, low-

er the media loading lever further.

18. Close the front cover.

8 Using the winding units

This section describes how to use the winding units.

Using the winding units allows printed media to be au-

tomatically wound around the media tube.

When using the winding units, follow the procedure

below to load roll media.

When using the winding units, make sure to load

media before start printing.

1. Attach the media tube to the winding units.

7 Loading the roll media

When using the winding units, make sure to use

the media tube included with this printer.

2. Load the roll media to the printer.

7 Loading the roll media

3. Press the [Forward ] key on the operation panel,

and feed the roll media to the media tube on the

winding unit.

4. Pull the roll media out of the media feed slot, and

attach the media to the media tube using tape so

that they are parallel to each other.

When setting roll media to the winding units:

Make sure that there are no wrinkles or slack

parts in either front or rear of the media.

Attach the roll media to the media tube with the

printing side facing outwards. The media cannot

be wound if it is attached with the printing side

facing inwards.

Cut both ends of the roll media so that the media

can be wound correctly as shown below.

a. Front

b. Rear

5. Press the [Forward ] key, and wind the roll media

around the media tube of the winding unit approxi-

mately one and half times.

This completes attaching the roll media to the me-

dia tube.

No.

Name

1

Media tube

No.

Name

2

Roll media

No.

Name

1

Roll media

2

Media tube

No.

Name

3

Cushioning roller

4

Tape

No.

Name

1

Media loading lever

No.

Name

1

Front cover

No.

Name

1

Media loading lever

NOTE

NOTE

NOTE

NOTE