RJ-900X series OPERATION MANUAL

Before using

3-59

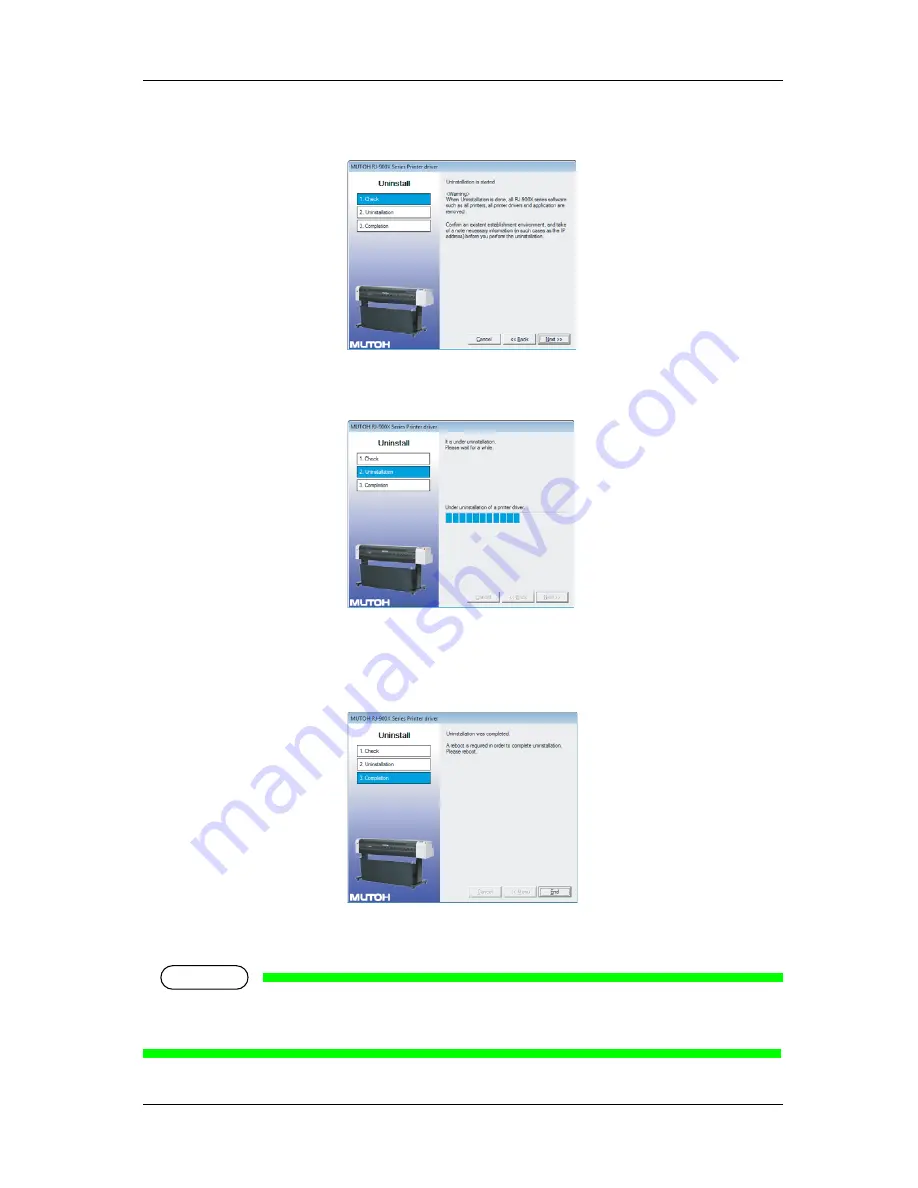

9. Check the precautions before uninstallation, and then click "Next".

•

Uninstallation starts.

•

The next screen is displayed.

10. Click "End".

•

This completes the printer driver installation.

NOTE

• The printer driver is completely deleted from the system after Windows is restarted.When

upgrading the printer driver, make sure to restart Windows.

Содержание DrafStation RJ-900X

Страница 2: ......

Страница 8: ...RJ 900X series OPERATION MANUAL 6...

Страница 20: ...Safety instructions RJ 900X series OPERATION MANUAL 1 8...

Страница 34: ...Product overview RJ 900X series OPERATION MANUAL 2 14...

Страница 48: ...Before using RJ 900X series OPERATION MANUAL 3 14 No Name 1 Roll media 2 Roll media fixing belt 2 1...

Страница 95: ...RJ 900X series OPERATION MANUAL Before using 3 61 3 Change the settings as required and then click OK...

Страница 104: ...Before using RJ 900X series OPERATION MANUAL 3 70...

Страница 202: ...Maintenance RJ 900X series OPERATION MANUAL 5 38...

Страница 226: ...Troubleshooting RJ 900X series OPERATION MANUAL 6 24...

Страница 236: ...Appendix RJ 900X series OPERATION MANUAL 7 10...

Страница 242: ...RJ 900X series OPERATION MANUAL A 6...

Страница 243: ......

Страница 244: ......