Mueller Model D Fre-Heater Installation and Operation Manual

Effective March 1, 1993

Part No. 8800430

Revised November 6, 2019

2.4 INSTALLING WATER PIPING (CONTINUED)

A cold water bypass line should always be provided so the Fre-Heater(s) can be bypassed for service without

shutting down the total water heating system.

Particular care should be paid to the hot water outlet connection on Fre-Heaters with 1

1

⁄

2

" FPT water connections.

A pipe nipple (preferably brass) should be used so this joint can be securely tightened and retightened should it

become loose. A copper pipe thread to sweat connector should not be used for this connection.

IMPORTANT: Be sure there are no leaks at the water connections that might cause the insulation to

become wet.

IMPORTANT: To reduce the risk of excessive temperatures and pressures in this water heater, a pressure

temperature relief valve has been installed by the manufacturer and should not be removed. This valve

should be provided with a

3

⁄

4

" drain line oriented so any discharge from the valve will exit within 6" above

or at any distance below the structural floor and cannot contact any live electrical part. The discharge

opening must not be blocked or reduced in size under any circumstances. Any additional protective

equipment required by local codes must also be installed. In the event the pressure temperature relief

valve is damaged or otherwise needs replacement, a combination pressure and temperature relief valve,

certified by a nationally recognized testing laboratory that maintains periodic inspection of production

of listed equipment, as meeting the requirements for ANSI Z21.22, “Relief Valves for Hot Water Supply

Systems,” should be installed. The valve must be marked with a maximum set pressure of 150 psig for use

on all Model “D” Fre-Heaters.

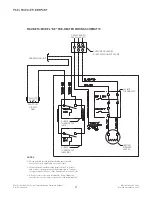

For commercial applications, an electrically operated water dump valve (Mueller Part No. 8824074) is provided to

be installed on the outlet side (hot) of the Model “DE” Fre-Heater (see Figure 5). It should be screwed into a

3

⁄

4

" FPT

tee fitting and installed either at the tank outlet or at a more convenient location downstream of the Fre-Heater.

If the Fre-Heater is a part of a multiple water heater system, a check valve should be installed in the hot water line

following the dump valve. This valve is a part of the temperature regulating/limiting system for the Fre-Heater

and should not be bypassed or ignored; however, an optional hot gas bypass can be used in place of the water dump

valve. Since the water dump valve may discharge scalding water when the tank exceeds 180°F in temperature,

precaution should be taken to divert or direct the flow of this valve to a safe place, preferably a drain. Piping should

be supported on both sides of the valve to avoid damaging the valve body.

IMPORTANT: If a water mixing valve is installed in the system, make sure that check valves are in both

hot and cold water lines. If this precaution is not taken, hot water may be drawn into the cold water

system under certain system operating conditions.

In some Fre-Heater systems, as in some standard water heating systems, thermal expansion of the water as it is

being heated can be great enough to cause the pressure temperature relief valve to leak or open. Should this be a

problem, we recommend the installation of a thermal expansion tank. See Section 6.0, “Appendix A.”‘

A “Therm-X-Trol” thermal expansion absorber or similar product can be piped in the system. For proper sizing of

the expansion tank, please consult your supplier. Typically, an expansion tank having a volume of 10 or more gallons

would be required for a Model “D” Fre-Heater with a water temperature of 140°F. See Appendix A for installation

procedures. A thermal expansion absorber is provided with all dairy farm models.

7