4

CENTURY, B-50-B18 AND B-50-B24 FIRE HYDRANTS

Installation, Operation, Inspection and Maintenance

joint of existing nozzle and re-pouring and caulking

joint for new nozzle. Resilient sealed nozzle may be

replaced using kit available from Mueller Canada.

If leakage through drains has been noted with hydrant

in open position, drain lever washers should be

replaced. (See directions for removal of internal parts.)

If hydrant does not drain or drains very slowly, the

drains should be flushed. Remove a cap and open

hydrant so barrel fills with water. Replace cap. Open

the hydrant valve approximately two turns. This

unseats the hydrant valve and allows the hydrant

barrel to be pressurized while still holding the drain

open. Check for proper drainage.

Lubricate nozzle cap threads with No.1 multi-purpose

grease. Since the bearing housing is sealed with O-

rings, it is not normally necessary to grease the

operating head.

Century Hydrants

– Drive cover pins through cover

into bearing housing and lift cover over operating nut.

Cover pins can be easily removed from clearance hole

in bearing housing and re-used.

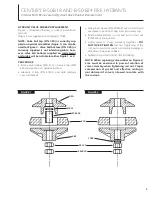

REMOVAL OF INTERNAL PARTS

IF REMOVAL OF INTERNAL parts is required, the fol low -

ing sequence must be followed:

• Shut off water in line leading to hydrant.

• Open hydrant valve.

• Remove cover.

• Cover is held in place by bonnet pins. Remove pins and

lift cover over operating nut.

• Remove housing bolts.

• Remove complete housing (operating nut, housing

cover, thrust bearing and housing) as a unit by

continuing to turn operating nut in opening direction

until hydrant rod threads are disengaged. Carefully lift

complete housing from hydrant to prevent damage

to O-rings.

• Place seat wrench over the rod. Turn to left

(counter-

clockwise)

to unscrew hydrant seat from drain ring.

• Remove seat wrench from hydrant rod.

• Lift out hydrant rod with completely assembled work -

ing parts attached.

• Before threading hydrant seat into drain ring, lubri -

cate threads and face of seat gasket lightly.

• To re-assemble, reverse above procedure.

Non-Draining Hydrants

– Non-draining (plugged)

hydrants should be clearly identified. Unauthorized

use of non-draining hydrants can result in damage or

may render the hydrant inoperable – additional

supervision of these hydrants is required during

freezing conditions.

Slight valve leakage on non-draining hydrants can

result in damage and/or inoperable hydrants.

It is advisable to check non-draining hydrants for

water in the barrel several hours after the initial

inspection and pump-out has been completed.

Proper Drainage

– Close hydrant and remove a

nozzle cap. Drainage rate should be sufficiently rapid

that a suction can be felt when palm is placed over

nozzle opening.

Check for presence of water in the hydrant barrel by

using a plumb line or other suitable method.

NOTE: Water in the barrel of a non-draining

hydrant is an indication of leakage in the area of

the main valve and complete servicing of hydrant

will be required.

Water in the barrel of a drain type hydrant is an

indication of obstructed drain passage or a high

water table condition. Note condition and proceed

with inspection – if drains are verified to be

functioning properly, consideration should be

given to converting hydrant to non-draining type.

MAINTENANCE

If needed, add grease by removing the lubricating screw

in the top of the operating nut (do not use excessive

greasing pressure).

Replace any damaged caps, chains, etc., as noted on

inspection of external condition. If hydrant requires

painting, this should be done after all maintenance

has been completed.

If valve leakage has been noted, valve rubber and seat

gasket should be inspected and replaced if damaged.

(See directions for removal of internal parts.) Replace

any defective cap gaskets.

With "Leaded-In" type nozzles, a heavy blow on a

nozzle cap may cause loosening of the nozzle. If

leakage has been noted at the leaded joint, remove

cap and re-caulk nozzle. If nozzle has been damaged,

"Leaded-In" type can be replaced by melting out lead

Содержание B-50-B18

Страница 7: ...7 CENTURY B 50 B18 AND B 50 B24 FIRE HYDRANTS Notes...

Страница 8: ......