Level Plus

®

Tank SLAYER

®

Operation Manual

I

44

I

13.4.2 FMC XP

13.4.2.1 Specific Conditions of Safe Use

1. Warning: The equipment contains non-metallic enclosure and

process parts. To prevent the risk of electrostatic sparking, the

non-metallic surface should only be cleaned with a damp cloth.

Painted surface of the equipment may store electrostatic charge

and become a source of ignition in applications with a low relative

humidity <~30% relative humidity where the painted surface is

relatively free of surface contamination such as dirt, dust or oil.

Cleaning of the painted surface should only be done with a damp

cloth.

2. Cables shall be rated > 5°C above maximum ambient

temperature.

3. To maintain the ingress protection rating of IP65, Teflon tape

(3 wraps) or pipe dope shall be used. Refer to Installation

Instructions.

4. The equipment can be installed in the boundary wall between

an EPL Ga area and the less hazardous area, EPL Gb. In this

configuration, the process connection is installed in EPL Ga, while

the transmitter housing is installed in EPL Gb. Refer to installation

instructions.

5. Flexible gauges have a minimum bend diameter of 381mm

(15 inches).

6. Flamepaths not for repair.

7. The applicable temperature class, process temperature range and

ambient temperature range of the equipment is as follows;

• T3 with Process Temperature Range of -40°C to 150°C

• T4 with Process Temperature Range of -40°C to 135°C

• T5 with Process Temperature Range of -40°C to 100°C

• T6 with Process Temperature Range of -40°C to 85°C

• Ambient Temperature Range -40°C < Ta < 71°C

8. When mounting on a MLG (magnetic level gauge) make sure the

electronic head and pressure barrier have a minimum spacing of

5 inches. See Installation Manual for detail.

9. When EPL Ga or Da is required, parts of the equipment containing

light metals (Aluminum or Titanium) shall be protected from

impact so that impact or friction sparks cannot occur, taking into

account rare malfunction. Measures to prevent impact or friction

sparks when using the equipment containing light metals include

but are not limited to:

• Mounting the probe vertically

• No mechanical agitation shall be used

• Use of stilling wells to mitigate effect of agitation.

• Limit rate of change of level to values such that friction sparks

cannot occur

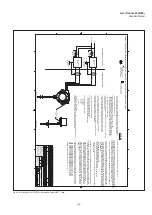

Fig. 44: Explosion proof, FMC label, Modbus or DDA Housing Option G, H, or L

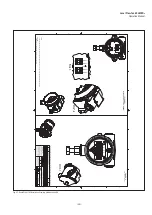

Fig. 45: Explosion proof, FMC label, Modbus or DDA, Housing Option D, E

Fig. 46: Explosion proof, FMC label, HART

®

, Housing Option G, H, or L

Fig. 47: Explosion proof, FMC label, HART

®

, Housing Option D, E

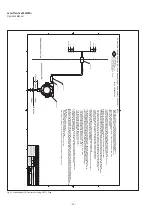

1

1

2

2

A

A

B

B

REV

ECO #

DESCRIPTION

TITLE

SIZE DWG NO.

REV

PRODUCT LINE

SCALE:

BY

DATE

SHEET

OF

UNLESS OTHERWISE SPECIFIED

TOLERANCES

0 PLACES

MM

1 PLACE

MM

ANGLES

0.5

0.1

- THREAD DEPTHS ARE TO MIN. FULL THDS

- DRILL DEPTHS ARE TO FULL DIA.

- REMOVE BURRS AND SHARP EDGES

- DO NOT SCALE PRINT

- MACHINED SURFACE FINISH 3.2uM [125 uIn]

PROPRIETARY DATA

THE INFORMATION AND DESIGN(S) DISCLOSED

HEREIN ARE THE PROPERTY OF MTS SYSTEMS

CORPORATION AND MAY NOT BE USED,

REPRODUCED OR DISCLOSED IN ANY FORM

EXCEPT AS GRANTED IN WRITING BY MTS

SYSTEMS CORPORATION. THIS RESTRICTION

EXCLUDES INFORMATION THAT IS IN THE

PUBLIC DOMAIN OR WAS LEGITIMATELY IN THE

PRIOR POSSESSION OF THE RECIPIENT.

m

MTS SYSTEMS CORPORATION

SENSORS DIVISION

3001 SHELDON DRIVE, CARY, NC 27513

ME TR IC

FIRST

ANGLE

A

551706-x

A

1

1

DRAWN BY: MS

***NO REVISIONS SHALL BE MADE WITHOUT THE NOTIFICATION TO APPROVAL AGENCY(S).***

A

MS

7/28/16

MTS Systems Corporation

Sensors Division

3001 Sheldon Drive, Cary, N.C. 27513

Level Plus Transmitter

FM16CA0130X

INSTALL PER #

# 651552-2/

651595-2

MAX. PRESSURE 1000 PSI (RIGID SENSOR)

MAX. PRESSURE 435 PSI (FLEX SENSOR)

INPUT: 28V (120mA)max

OUTPUT: RS485

WARNING

: DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS

PRESENT. FOR ZONE INSTALLATIONS, A SEAL SHALL BE INSTALLED WITHIN 50mm OF

THE ENCLOSURE. FOR DIVISION INSTALLATIONS A SEAL SHALL BE INSTALLED WITHIN 18 INCHES

OF THE ENCLOSURE

ATTENTION

: NE PAS OUVRIR UNE ATMOSPHÈRE EXPLOSIVE PRESENT.

POUR INSTALLATIONS DE ZONE, UN SORTIE EST INSTALLÉ DANS LES 50 mm DE L'ENCEINTE.

POUR INSTALLATIONS DE DIVISION ALE SORTIE EST INSTALLÉ DANS LES 18 POUCES DE L'ENCEINTE

EXPLOSIONPROOF CL. I, DIV. 1, GR BCD T6...T3

.

Ex db IIB+H2 T6...T3 Ga/Gb

Ta = -40°C to +71°C ; IP 65

7957

RELEASE FOR PRODUCTION

(ACP) LABEL, LP, XP CANADA - DIGITAL

R

FM

APPROVED

P/N 551706-1 REV B

LEVEL

1:1

!

C

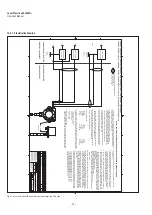

1

1

2

2

A

A

B

B

REV

ECO #

DESCRIPTION

TITLE

SIZE DWG NO.

REV

PRODUCT LINE

SCALE:

BY

DATE

SHEET

OF

UNLESS OTHERWISE SPECIFIED

TOLERANCES

0 PLACES

MM

1 PLACE

MM

ANGLES

0.5

0.1

- THREAD DEPTHS ARE TO MIN. FULL THDS

- DRILL DEPTHS ARE TO FULL DIA.

- REMOVE BURRS AND SHARP EDGES

- DO NOT SCALE PRINT

- MACHINED SURFACE FINISH 3.2uM [125 uIn]

PROPRIETARY DATA

THE INFORMATION AND DESIGN(S) DISCLOSED

HEREIN ARE THE PROPERTY OF MTS SYSTEMS

CORPORATION AND MAY NOT BE USED,

REPRODUCED OR DISCLOSED IN ANY FORM

EXCEPT AS GRANTED IN WRITING BY MTS

SYSTEMS CORPORATION. THIS RESTRICTION

EXCLUDES INFORMATION THAT IS IN THE

PUBLIC DOMAIN OR WAS LEGITIMATELY IN THE

PRIOR POSSESSION OF THE RECIPIENT.

m

MTS SYSTEMS CORPORATION

SENSORS DIVISION

3001 SHELDON DRIVE, CARY, NC 27513

ME TR IC

FIRST

ANGLE

A

551706-x

A

1

1

DRAWN BY: MS

***NO REVISIONS SHALL BE MADE WITHOUT THE NOTIFICATION TO APPROVAL AGENCY(S).***

A

MS

7/28/16

MTS Systems Corporation

Sensors Division

3001 Sheldon Drive, Cary, N.C. 27513

Level Plus Transmitter

FM16CA0130X

INSTALL PER #

# 651552-2/

651595-2

MAX. PRESSURE 1000 PSI (RIGID SENSOR)

MAX. PRESSURE 435 PSI (FLEX SENSOR)

INPUT: 28V (120mA)max

OUTPUT: RS485

WARNING

: DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE IS

PRESENT. FOR ZONE INSTALLATIONS, A SEAL SHALL BE INSTALLED WITHIN 50mm OF

THE ENCLOSURE. FOR DIVISION INSTALLATIONS A SEAL SHALL BE INSTALLED WITHIN 18 INCHES

OF THE ENCLOSURE

ATTENTION

: NE PAS OUVRIR UNE ATMOSPHÈRE EXPLOSIVE PRESENT.

POUR INSTALLATIONS DE ZONE, UN SORTIE EST INSTALLÉ DANS LES 50 mm DE L'ENCEINTE.

POUR INSTALLATIONS DE DIVISION ALE SORTIE EST INSTALLÉ DANS LES 18 POUCES DE L'ENCEINTE

EXPLOSIONPROOF CL. I, DIV. 1, GR. BCD T6...T3

Ex db IIB+H2 T6...T3 Ga/Gb

Ta = -40°C to +71°C ; IP 65

7957

RELEASE FOR PRODUCTION

(ACP) LABEL, LP, XP CANADA - DIGITAL

R

FM

APPROVED

P/N 551706-2 REV B

LEVEL

1:1

!

C

Level Plus Transmitter

FM16CA0130X

MTS Systems Corporation

Sensors Division

3001 Sheldon Drive, Cary, N.C. 27513

WARNING

: DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE

PRESENT FOR ZONE INSTALLATIONS, A SEAL SHALL BE INSTALLED WITHIN 50mm OF

THE ENCLOSURE. FOR DIVISION INSTALLATIONS A SEAL SHALL BE INSTALLED WITHIN 18 INCHES

OF THE ENCLOSURE

ATTENTION

: NE PAS OUVRIR UNE ATMOSPHÈRE EXPLOSIVE PRESENT

POUR INSTALLATIONS DE ZONE, UN SORTIE EST INSTALLÉ DANS LES 50 mm DE L'ENCEINTE.

POUR INSTALLATIONS DE DIVISION ALE SORTIE EST INSTALLÉ DANS LES 18 POUCES DE L'ENCEINTE

EXPLOSIONPROOF CL. I, DIV. 1, GR. BCD T6...T3

Ex db IIB+H2 T6...T3 Ga/Gb

Ta = -40°C to +71°C ; IP 65

INSTALL PER # 651553-2/651597-2

MAX. PRESSURE 1000 PSI (RIGID SENSOR)

MAX. PRESSURE 435 PSI (FLEX SENSOR)

INPUT: 28V (120mA)max

OUTPUT: 4-20mA

FM

C

APPROVED

P/N 551708-x RevB

R

!

Level Plus Transmitter

FM16CA0130X

MTS Systems Corporation

Sensors Division

3001 Sheldon Drive, Cary, N.C. 27513

WARNING

: DO NOT OPEN WHEN AN EXPLOSIVE ATMOSPHERE

PRESENT FOR ZONE INSTALLATIONS, A SEAL SHALL BE INSTALLED WITHIN 50mm OF

THE ENCLOSURE. FOR DIVISION INSTALLATIONS A SEAL SHALL BE INSTALLED WITHIN 18 INCHES

OF THE ENCLOSURE

ATTENTION

: NE PAS OUVRIR UNE ATMOSPHÈRE EXPLOSIVE PRESENT

POUR INSTALLATIONS DE ZONE, UN SORTIE EST INSTALLÉ DANS LES 50 mm DE L'ENCEINTE.

POUR INSTALLATIONS DE DIVISION ALE SORTIE EST INSTALLÉ DANS LES 18 POUCES DE L'ENCEINTE

EXPLOSIONPROOF CL. I, DIV. 1, GR. BCD T6...T3

Ex db IIB+H2 T6...T3 Ga/Gb

Ta = -40°C to +71°C ; IP 65

INSTALL PER # 651553-2/651597-2

MAX. PRESSURE 1000 PSI (RIGID SENSOR)

MAX. PRESSURE 435 PSI (FLEX SENSOR)

INPUT: 28V (120mA)max

OUTPUT: 4-20mA

FM

C

APPROVED

P/N 551708-x RevB

R

!

13.4.2.2 Labels