13

Premier GP-9 Diesel Engine Operating Instructions

3. Once the motor mount screw has been removed, pull the motor away from

the truck block and lightly coat the motor worm gear and bronze drive gear (in

the truck block) with grease.

4. Reassemble the truck and motor, being careful not to pinch any wires

between the truck block and motor mount.

5. After repeating the procedure for the other motor, reassmble the chassis and

body, being careful that the wire harnesses are not caught between the chassis

and body and reinstall the chassis screws.

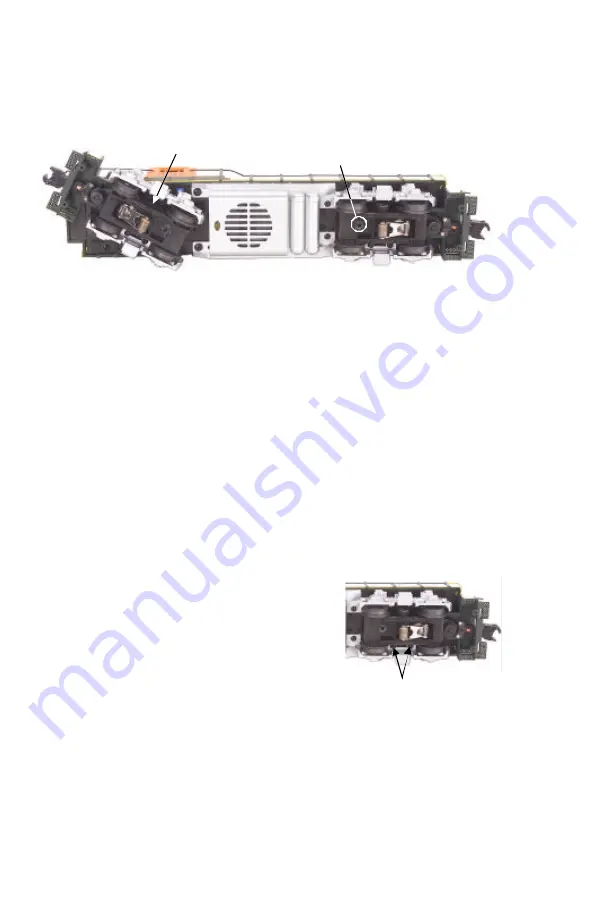

Lubricate the outside truck block idler and drive gears with grease. Use the

diagram shown in Figure 7 above as a guide and add grease to the points

marked with a “G.”

Periodically check the locomotive wheels and pickups for dirt and buildup,

which can cause poor electrical contact and traction as well as prematurely

wear out the neoprene traction tires.

Traction Tire Replacement Instructions

Your locomotive is equipped with two neoprene

rubber traction tires on each powered truck block.

While these tires are extremely durable, you may

need to replace them at some point.

First, remove the truck sides from the truck block.

To do this, turn your engine upside down. If there

are visible Phillips screw heads between the truck

frame and truck block (see Fig. 8), go to step A. If

not, go to step B.

A. Remove the two Phillips screws that attach the

truck sides to the truck block.

Grease Idler Gear (G)

Motor Mount Screw

Figure 7. Locations of Greasing Points on the Locomotive

Truckside

Screws

Figure 8. Truckside

Mounting Screws to Access

the Traction Tires