Maintenance & Adjustments

6

12

WARNING!

Before cleaning, lubricating, repairing

or inspecting, disengage the control lever and stop

engine. Disconnect the spark plug wire and ground

it against the engine to prevent unintended starting.

Always wear safety glasses during operation or while

performing any adjustments or repairs.

Maintenance

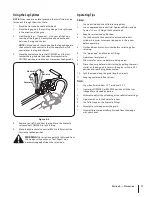

Hydraulic Fluid

Check the hydraulic fluid level in the log splitter reservoir tank

before each use. Maintain the fluid level to just below the oil plug.

Have the hydraulic fluid in the reservoir changed every 100 hours

of operation. See your authorized service dealer to have the

hydraulic fluid changed.

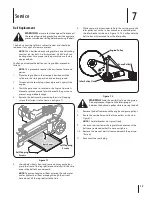

Beam & Splitting Wedge

Before each use, lubricate the top and bottom of the beam (where

it comes into contact with the cylinder) with engine oil.

Hardware & Hose Clamps

Before each use, check to see if the hose clamps on the suction

hose (attached to the side of the pump) are tight. Check the hose

clamps on the return hose at least once a season. Check all the

hardware at least once a season and tighten any nuts, bolts, etc.

that are loose.

Off-Season Storage

When the log splitter will not be used for an extended period of

time, prepare it for storage as follows.

WARNING!

Never store the machine with fuel in

the fuel tank inside of a building where fumes may

reach an open flame or spark, or where ignition

sources are present such as hot water and space

heaters, furnaces, clothes dryers, stoves, electric

motors, etc.

1.

Clean the log splitter thoroughly.

NOTE:

Using a pressure washer or garden hose to clean

your machine is not recommended. They may cause

damage to bearings or the engine. The use of water will

result in shortened life and reduce serviceability.

2.

Wipe the log splitter with an oiled rag to prevent rust,

especially on the wedge and the beam.

3.

Drain the fuel tank. Always drain the fuel into an approved

container outdoors, away from open flame. Be sure that the

engine is cool before draining the fuel. Do not smoke while

handling fuel.

4.

Start the engine and let it run until the fuel lines and the

carburetor are empty.

5.

Remove the spark plug. Holding a rag over the cylinder hole,

pour approximately 1⁄2 ounce (approximately one tablespoon)

of engine oil into cylinder and crank slowly to distribute the oil.

6.

Replace the spark plug.

7.

Do not store the gasoline from one season to another.

8.

Replace your gasoline can if it starts to rust. Rust and/or dirt

in the gasoline will cause problems.

NOTE:

For information on storing the engine refer to the

Engine Operator’s Manual.

9.

Store the log splitter in a clean, dry area. Do not store it

next to any corrosive materials, such as fertilizer. DO NOT

store the machine in an upright position.

NOTE:

If storing in an unventilated or metal storage shed, be

certain to rustproof the equipment by coating with a light oil

or silicone.

Maintenance Schedule

After First 5 Hours

Before Each Use

Every Season

Every Season or 100

Hours

Check Hydraulic Fluid

P

P

Lubricate Beam & Splitting wedge

P

Check Hardware & Hose Clamps

P

Replace Hydraulic Fluid

P