39

MCTC manual

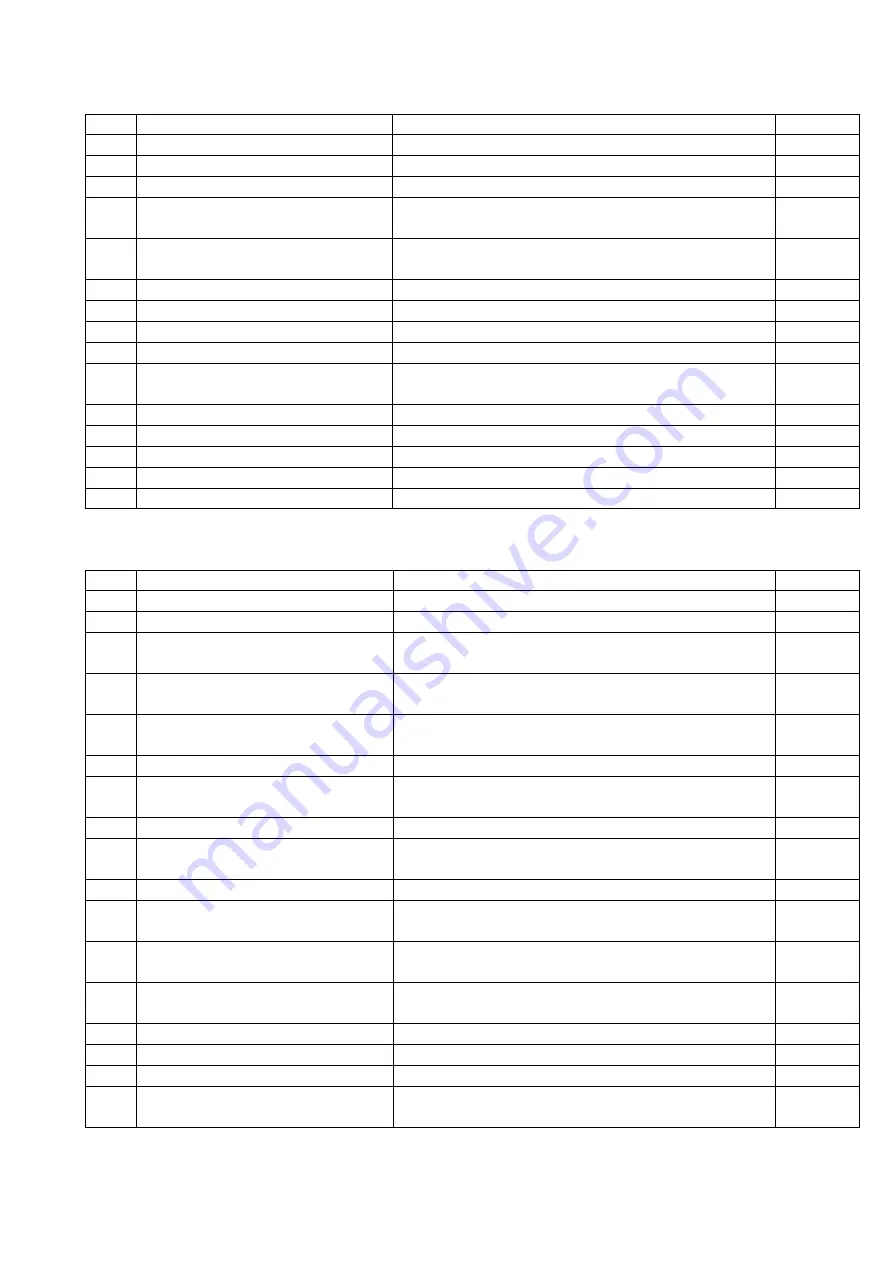

4.6.3

Unit events

Unit events can be set separately for each unit in a group.

Code Event

Description

Default

3001 Minimum motor speed! (<0.1 RPM) Required motor speed is too low

Warning

3002 Max RPM Exceeded

Required motor speed is too high

Warning

3003 CAN bus connection failure

CAN bus communication error

Warning

3004 Motor connection failure!

Short circuit detected!

Motor or cabling short circuit detected

Warning

3005 Motor connection failure!

Open connection detected!

Motor defect or not connected

Warning

3007 Load cell connection failure!

Load cell not connected or defective

Alarm

3008 Door open!

MCHybrid door open during production

Softalarm

3009 Weigh bin not empty

MCHybrid weigh bin not empty at production start

Softalarm

3010 Weigh bin missing

MCHybrid weigh bin not placed, or placed wrong

Alarm

3011 Actual batch weight exceeds

maximum batch weight!

More material is dosed in the weigh bin than allowed

Warning

3012 Emergency button pressed!

MCHybrid emergency button activated (Future use)

Alarm

3013 Pause time exceeded!

MCHybrid paused for more 10 minutes

Alarm

3014 Low mixer

MCHybrid200 mixer empty

Warning

3015 Pellets not loaded

Pellets are not sucked to disk

Alarm

3016 Not calibrated

MCNexus disk is not calibrated

Alarm*

4.6.4

Component events

Component events can be set separately for each component in a unit.

Code Event

Description

Default

4001 Empty level!

Hopper level below empty level

Warning

4002 Low level!

Hopper level below low level

Warning

4003 High high level!

Hopper level above High High level (no RPM

regulation)

Warning

4004 Maximum deviation exceeded!

Deviation between set and act detected based on a

rough weight measurements

Warning

4005 Maximum deviation exceeded!

Deviation between set and act consistently bigger

than deviation alarm setting [default: 25%] based

Warning

4006 Maximum deviation exceeded!

MCHybrid deviation between set and act detected

Warning

4007 Suggested correction to high!

Suggested RPM correction too big, wrong dosing tool,

material rat-holing or hopper empty

Off

4008 Total correction to high

RPM correction too big, wrong dosing tool!

Off

4009 Filling system unable to load

material!

Fill system cannot complete filling within the set time

period

Warning

4010 Slide not closed!

Optional slide not closed

Warning

4011 Calculated dosing weight too small,

component skipped!

MCHybrid component dosing too small, component

skipped for this batch

Warning

4012 Material flow error! Hopper

empty?

MCHybrid component hopper material flow detected,

hopper (almost) empty?

Warning

4013 Minimum valve capacity reached!

Check valve configuration.

MCHybrid component skipped continuously, wrong

dosing valve mounted?

Warning

4014 Hopper Missing

Hopper is removed from unit

Alarm

4015 Pellets Deviated

MCNexus deviation between set and act detected.

Off

4016 Pellets Missing

MCNexus is missing pellets during dosing cycle.

Warning

4017 Filling limiting measurement time!

Time between filling cycles too short, system cannot

measure accurately.

Warning

* This event cannot be configured.