14/16

NT 1401-G00 10 18 TYPHON II e

The operator should remain nearby the equipment throughout

the use to ensure the proper functioning of the system.

4.1 Lubricant recommendations

MOUVEX BSC3 oil is recommended for 20R and 30R

configuration, whereas it is imperative for 13R/15L and

19R/22L.

A start up oil change has to be made after one week or

10 working hours. Not performing this oil change will void

the warranty.

For the first week or 10 working hours, you can choose

a standard mineral oil.The standard mineral oil grade will

be selected according to the ambient temperature under

which the compressor will be operated :

- Below -10°C. . . . . . . . . . . . . . SAE 10 W 40

- Between -10°C and 30°C . . . SAE 15 W 40

- Above 30°C . . . . . . . . . . . . . . SAE 15 W 50

With BSC3 oil, oil change is recommended every year or

600 working hours that the compressor is equipped with

or without a multiplier.

I

n case of operations done

under minus 25°C

, BSC3 oil

viscosity sharply increases and can generate starting

troubles. It will be necessary, in that case, to preheat the

compressor body.

It is also allowed to use oil SAE 5W40 temporarily allowing

to tolerate -35°C.

That implies the following constraints :

• Oil must be replaced every 100 operating hours.

• Imperative return to the BSC3 when the temperature

becomes again positive.

Oils BSC and SAE are miscible; the passage of the one

with the other thus does not imply particular procedure of

cleaning.

Compressors can be used with an external oil cooler in

case of intensive applications (see Instructions 1401-AC00

O

IL

COOLER

SCREW

COMPRESSORS

MISTRAL B600

TYPHON II).

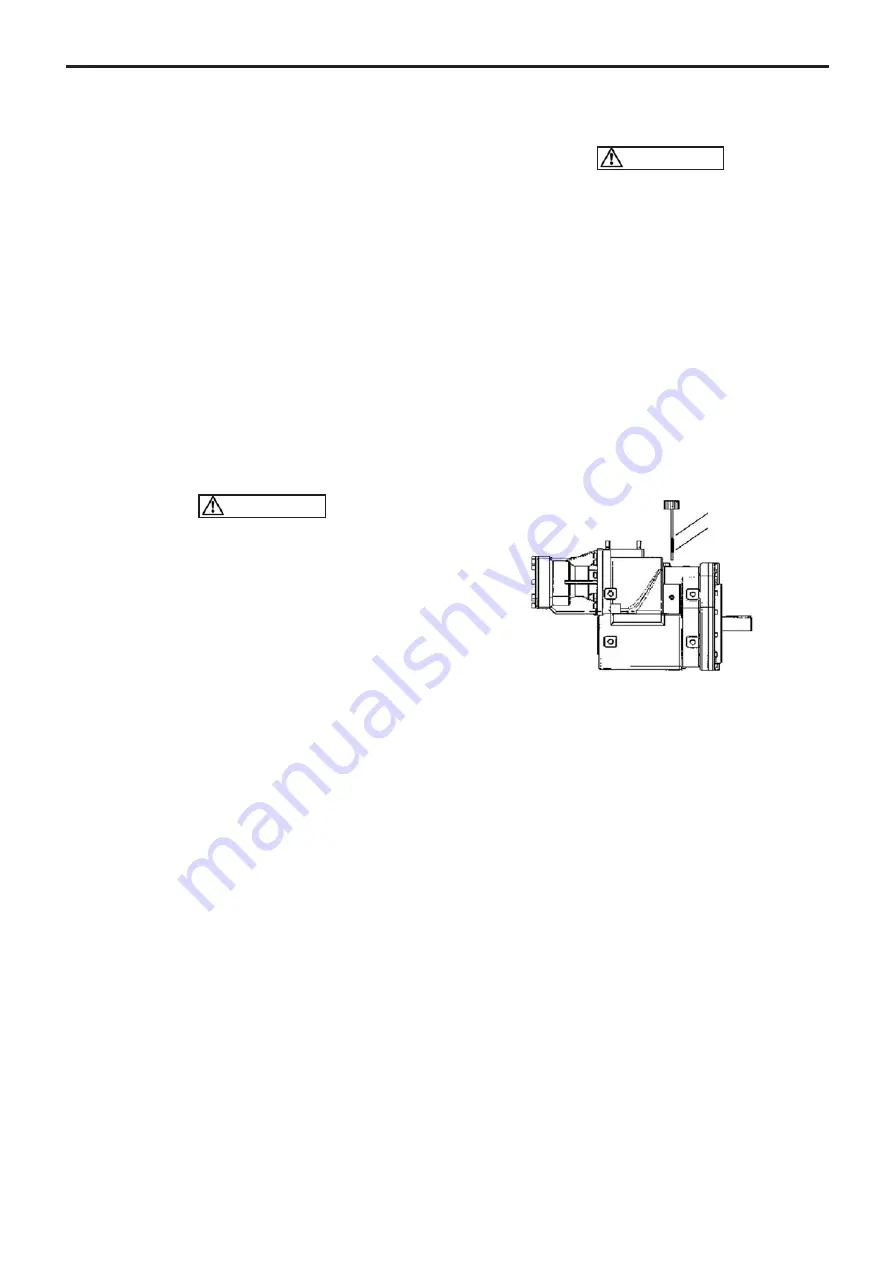

4.2 Filling of lubricant

Our packages are delivered without oil. The use of a

compressor with an oil level that is not located

between the two limits indicated by the gauge can lead

to important property damage and serious injuries.

The quantity of oil for each compressor is approximately :

• TYPHON II 20R - 30R . . . . . . . . .

6

l

• TYPHON II 13R/15L . . . . . . . . . .

7

l

• TYPHON II 19R/22L . . . . . . . . . .

7

l

Before starting the system, fill the casing with oil so that

the oil level is set between the min and max value of the

gauge.

NB : A residual volume of 0,5 l of oil may be present inside

the compressor when it leaves the factory.

After filling, the level must under no circumstances

exceed the maximum marker on the oil gauge (the level

is taken after the gauge has been completely screwed

onto the filling tube).

Max level

Min. level

CAUTION

CAUTION

4. USE OF COMPRESSOR