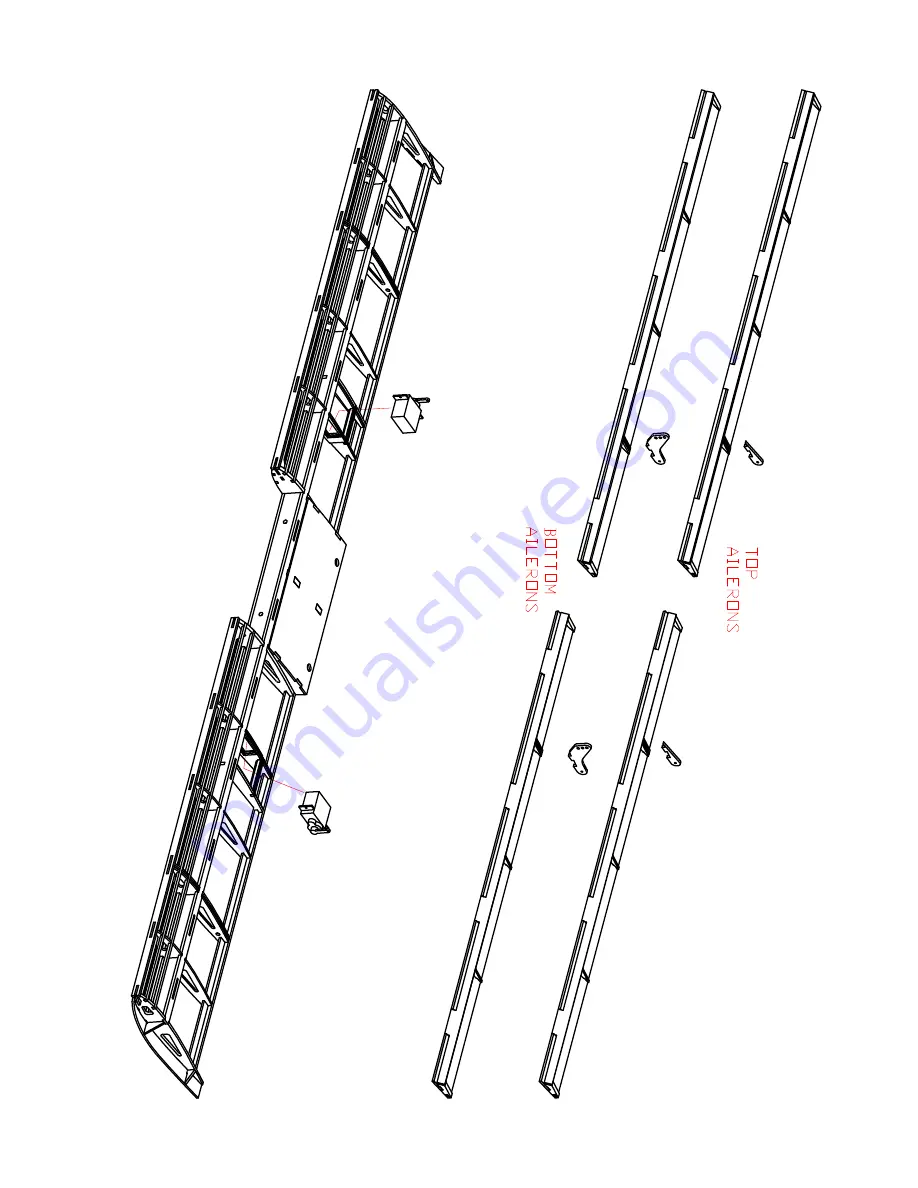

23. Glue in the control horns with Thick CA, as

shown in the images.

24. Power up your system and center

your aileron servos. Instal the long arm

that came with hour Hitec HS-55 servo,

so it is at a 90 degree angle to the servo.

25. Trim off the servo arm side that is not being used (will be inside

the wing), so the servo will fit into the wing.

26. Install the aileron servos into the wing, as shown, using the screws

included with the servo. Do NOT press to hard because you do not

want to accidentally break the ribs that the servo goes through. It helps

to hold the ribs from the top and bottom between your fingers while

installing the screws.

43