Copyright 2009 - Morse Mfg. Co., Inc.

Form PL400-72 (0804-0309) (Updated 10/2009)

Page 5

The Specialist In Drum Handling Equipment

Model 400A-72

Hydra-Lift, 72”, Manual Lift, Manual Tilt

Assembly Instructions for Morse Hydra-Lift Drum Karrier Model 400A-72

Serial Number 0804 to 0309 (MMYY)

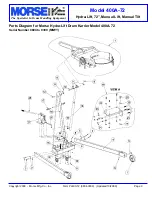

Step #1:

Place tower on floor, push-handle down. See figure 1.

Step #2:

Attach each leg (item 4) using two 3/8-16x3” grade 5 bolts

(item 2), flat washers (item 3), and lock nuts (item 13) as

shown. Wheels should be parallel when assembled properly.

See figures 1 & 2.

Step #6: Remove sealing plug from the top of hydraulic reservoir and fill reservoir with included container of hydraulic fluid. Replace sealing plug with

the included breather plug. Your Hydra-Lift Karrier is now ready for service. Please refer to the operating and maintenance instructions pro-

vided.

Step #3: Tip the tower up so it stands on the casters and wheels.

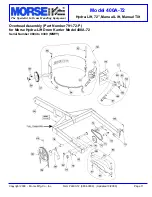

Step #4: Lift overhead assembly into position. A drift pin can help align the holes. Insert a greased clevis pin (item 12) through mast cap and boom. Install

a 5/8” washer (item 9) and 3/16” roll pin (item 8) in the end of the clevis pin. See figure 3.

Step #5: Next, connect the cylinder (item 16) to the overhead assembly: Align ram eye with holes in boom clevis plates and insert a greased clevis pin

(item 12) with four 5/8” washers (item 9). Place another washer (item 9) on outer end of clevis pin and drive a 3/16” roll pin (item 8) into the

hole at the end of clevis pin. See figure 4.

Please unpack and identify the following parts:

1 ea. Tower with hydraulic pump and cylinder, etc.

2 ea. Legs with wheels

1 ea. Overhead assembly with drum holder, etc.

1 ea. Package with hardware

NOTE: The clevis pins and mating surfaces at their joints should be

coated with grease during assembly.

fIguRE 4

fIguRE 3

fIguRE 1

fIguRE 2