Page 17

SYSTEM

Perforating

11.

Mount the other anvil ensuring that they have matched on the drive hub. Secure the

anvil to the hub ensuring not to over tighten grub screw as shown in fig 16.2.

12.

Slide the drive hub towards the perforating drive wheel until there is a clearance

of 0.5mm.

13.

To prevent damage to the blades or the anvils, do not force the drive wheel against

the hub.

14.

Fix the perforator stripper adjacent to the drive wheel and blade as shown.

15.

Operate the machine and test the perforations for form.

It is important that the drive hubs are arranged evenly across the width of the paper

in order to reduce the risk of jamming.

For multiple perforations repeat the above procedure.

Always remove blades and anvils once the perforating operation has been

completed to avoid marking on digital or delicate media.

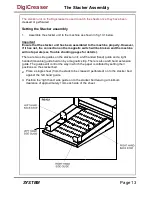

5

2

1

3

4

FIG 17.1

Fig 17.1

1

4

2

5

3

demonstrates a typical set-up for perforating sheets.

Perforating drive wheel with mounted blades

Drive hub with mounted anvils

Perforator stripper

Standard drive hub

Standard drive wheel

DigiCreaser

Содержание DigiCreaser

Страница 5: ...Page 5 SYSTEM BLANK PAGE DigiCreaser ...

Страница 29: ...Page 29 SYSTEM DigiCreaser ...