11

10

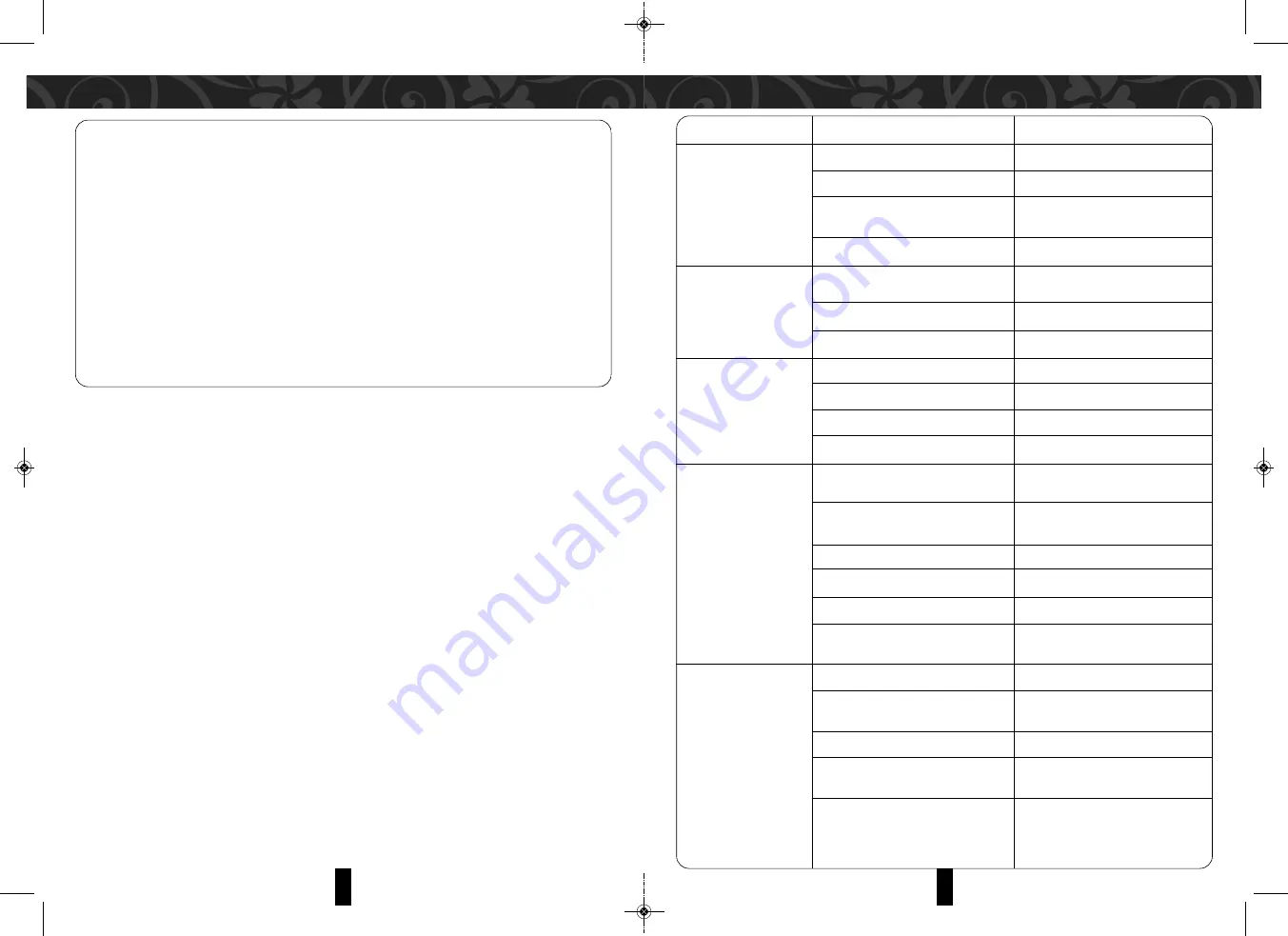

CLEANING AND MAINTENENCE

PROBLEM

CAUSE

SOLUTION

Lamp is not turned ON Bad wire connection. Repair or replace wires.

Motor is running

Lamp is fused. Change lamp.

No connection between lamp and power Repair or replace.

socket.

The quartz lamp transformer has burned out. Replace transformer.

Lamp is not turned ON Bad connection between power plug and Repair or replace.

Motor is not running power socket.

Power cord is damaged. Replace power cord.

Fuse of power board is damaged. Replace fuse.

Lamp is ON Motor is not Thermal cutout of motor is working. Wait for a while and turn on again.

running

Condenser malfunction. Replace condenser.

Motor malfunction. Replace motor.

Faulty power board and control board. Contact service center

Excessive vibration noise Ensure appliance is securely mounted. Check and ensure appliance is properly

increases mounted.

The connecting pieces of the fixed screws Tighten screws.

are loose.

Volute standing fixed screws are loose. Tighten screws.

Motor fixed screws are loose. Tighten screws.

Impeller installation is not in place. Install in place.

Impeller is damaged and balance piece Replace impeller.

is lost.

Poor suction Too much oil in filter. Clean filter.

The air convection in the kitchen is too big Reduce air convection and open doors and

or space sealing is too tight. windows moderately.

Higher installation height. Adjust to appropriate height.

Exhaust pipe is too long or has too many Install according to the manual.

turns.

Outdoor wind is too strong. Non-technical faults.

TROUBLESHOOTING

1. FOR BEST PERFORMANCE:

• Clean the exterior of the appliance once every three days.

• Clean and empty the oil inside the filter regularly.

• It is recommended to carry out a full maintenance service once every half yearly by qualified personnel

2. IMPORTANT STEPS TO REMEMBER FOR INTERNAL MAINTENANCE

• Turn off power supply.

• Remove filter and clean using a soft brush and reassemble after drying for next maintenance.

• Remove the smoke cover by pulling it upwards. Unscrew the air inlet cover and air frame to remove it. Loosen the

knob clockwise. Hold the wheel axle and pull out the impeller. Immerse the impeller into cleaning fluid around 10

minutes. Clean the oil on impeller with soft brush.

NOTE: These steps should preferably be carried out by a qualified person.

• Install the impeller back in place. Tighten the knob counter clockwise. Then install air inlet board, air inlet cover and

smoke cover in order.

• Regular maintenance is required to ensure optimum performance of the appliance.

MDH-923STOC(IM)281216.qxp_Layout 1 12/29/16 5:14 PM Page 6