18

424WBST Designer Woodburning Fireplaces

87D1506

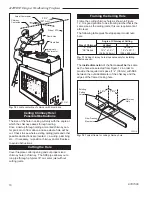

example of Determining Hearth extension

equivalents

To determine the thickness required for any

new

mate-

rial:

COMMON MATERIALS AND FACTORS

MATERIAL

K*

R

MINIMUM

THICKNESS

EH2416

Common Brick

0.458

5.0

1.09 0.50 in.**

0.10 5.46 in.**

(MHSC)

R Value is for 1/2 inch.

* Units of K = BTU/SQ FT/HR

/˚F/IN

** Thickness of Listed Material

FP533ADD

Addendum

6/1/99 djt

8/4/99 changed .2 to .1

one inch to 1/2 inch djt

FP533AD

Fig. 25

Hearth extension material factors.

FP719

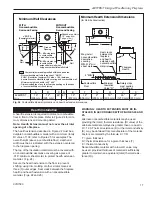

STR/CVR finish wall treatments

5/28/98

Wall Covering

Noncombustible

Decorative

Facing

Noncombustible

Decorative

Covering

Seal all cracks

between fireplace

surround and wall

materials with

noncombustible

material.

Seal crack

between fireplace

and hearth extension

with noncombustible

material.

2x4" Header -

Do not notch at

standoffs.

2x4"

Stud

Safety Strips -

Must be overlapped

56O

" minimum.

Hearth Extension

Insulation

Side View

NOTE:

5

/

O

"

air space

between

Outer Dome

and

combustible

materials

5

/

O

"

5

/

O

"

Outer Dome

FP719

Fig. 26

Finish wall treatments and gap sealing.

NEW

K of new material (per inch)

thickness

required =

X of listed

thickness K of listed material (per inch) material

example for Common Brick

T (new) = 5.0 / 0.458 x 0.50 in. =

5.46 in.

(new required

thickness).

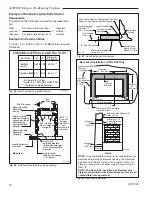

&0

4YPE"FLOOR

DJT

Safety Strips

Must be Over-

lapped 1/2" Min.

Minimum Insulation

Value R-0.94

1/4" Min. Thickness

Combustible

Floor

Noncombustible

Material 7

Z\₂

"

Max. Thickness

Seal Cracks Between Fireplace and Hearth

Extension with Noncombustible Material

Noncombustible

Material

Lower Surround

Fireplace

Hearth

FP1170

Fig. 27

Hearth extension dimensions.

2”

(51 mm)

2”

(51 mm)

Maximum

14”

(356 mm)

Maximum

10”

(254 mm)

A

A

&0

ALCOVEINSTALLATION

Minimum

33”

(838 mm)

Minimum

36” (914 mm)

6”

(152 mm)

Minimum

Minimum .030 Thick Stain-

less Steel Plate

Insulation with Minimum R

Value of 2.75

Minimum .030

Thick Stainless

Steel Plate

View A

NOTe:

If noncombustible material is not used between the

stainless steel plate and fireplace opening, the steel must

be attached to the front of the unit a minimum of four (4)

places on each piece with sheet metal screws no longer

than 1/2".

NOTe: The size of the insulation and stainless steel

plate must be within limits stated above and covers all

combustible framing material.

Fig. 28

Recessed installation.

FP1608

Hearth

Extension

Hearth Extension

Noncombustible

Material

(if desired)

Insulation

with Minimum

R Value

of 2.75

Recessed Installation - STR33/36 Only