Crimp Force Monitor

Doc. No: TM-638007950

Release Date: 03-21-13

UNCONTROLLED COPY

Page 15 of 21

Revision: A

Revision Date: 03-21-13

4.2.1

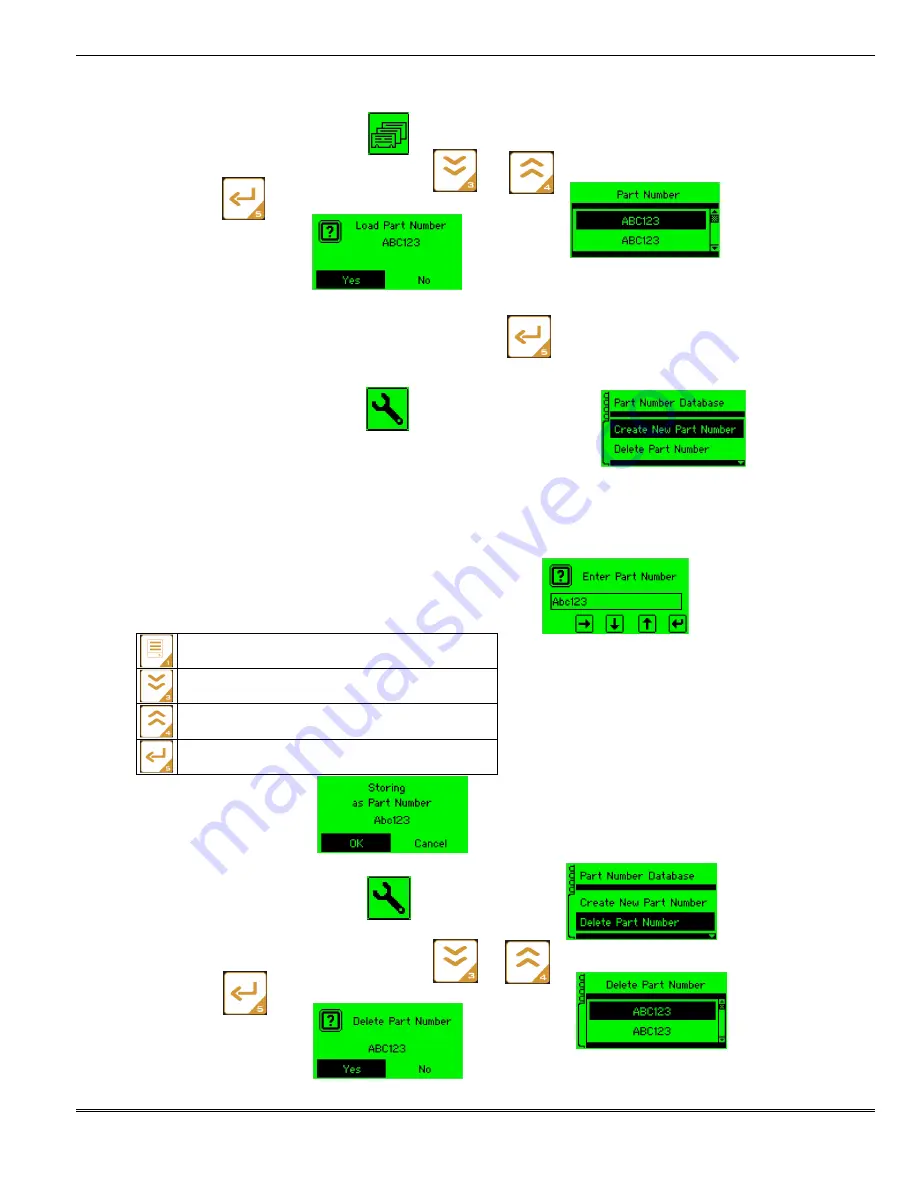

Loading a Part Number

1.

From the main menu, select the icon.

2.

Scroll through the part number list with the and keys.

3.

Press the button to select the highlighted part number.

4.

Confirm the selection.

5.

The crimp force monitor will automatically load the stored parameters and proceed to the learn screen.

6.

After the machine has been set-up and verified press to start the learn process.

4.2.2 Creating a New Part Number

1.

From the main menu, select the icon.

2.

Select

Create New Part Number

in the

Part Number Database

tab.

Configuration Parameters Stored in a New Part Number

The CFM will save the current configuration parameters under the entered name. The parameters from

the Signature Capture, Signature Analysis, Gross Tolerances and Learn Parameters are stored in the part

number database. Please refer to Appendix A for more information on the parameters stored for each

mode of operation.

3.

Enter a name for the new part number using the keypad.

Forward: Move the cursor to the next character

Down: Scroll down through available characters

Up: Scroll up through available characters

Enter: Finished entering Part Number name

4.

Confirm the selection.

4.2.3 Deleting a Part Number

1.

From the main menu, select the icon.

2.

Select

Delete Part Number

in the

Part Number Database

tab.

3.

Scroll through the part number list with the and keys.

4.

Press the button to delete the highlighted part number.

5.

Confirm the selection.