MOHAWK MODEL USL-6000-K

1-3

MOHAWK MODEL USL-6000-K SETUP

IMPORTANT

READ THIS MANUAL IN ITS ENTIRETY. BE FAMILIAR WITH PART NAMES AND HAVE A GOOD UNDERSTANDING

OF HOW THIS UNIT IS ASSEMBLED AND HOW INDIVIDUAL PARTS OPERATE BEFORE ASSEMBLING THE UNIT.

NOTE

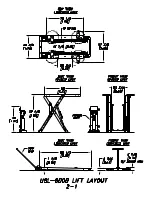

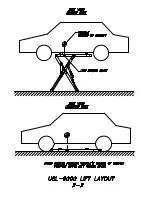

THE PLACEMENT OF THE UNIT IS DETERMINED BY THE TYPE ( LENGTH, WIDTH, HEIGHT ) OF VEHICLE BEING

SERVICED. ALLOW AMPLE ROOM (THREE TO FOUR FEET) FOR WALKWAYS ETC.

REVIEW THE

PACKING LIST (PG 1-4)

IN THIS

MANUAL TO VERIFY ALL SUPPLIED PARTS. IF

MISSING PARTS ARE NOTED, THEY CAN BE

OBTAINED BY CONTACTING YOUR LOCAL

MOHAWK DISTRIBUTOR,

BY CALLING

1-800-833-2006

OR FAXING TO

1-518-842-1289

.

REQUESTS CAN ALSO BE SENT BY E-MAIL TO

CUT ALL BANDING AND DISCARD. REMOVE LIFT

AND SHIPPING CRATE FROM PALLET. REMOVE

POWER UNIT DOLLY SUB-ASSEMBLY FROM CRATE

AND ASSEMBLE WHEELS.

SEE POWER UNIT

DOLLY ASSEMBLY DIAGRAM (PG 3-5)

REMOVE THE TANK PLUG ON THE POWER UNIT

RESERVOIR AND DISCARD.

VERIFY FLUID LEVEL. LEVEL SHOULD BE 1/2 INCH

BELOW UPPER TANK PORTS ON THE POWER UNIT

RESERVOIR WHEN UNIT IS FULLY LOWERED.

INSTALL THE BREATHER CAP.

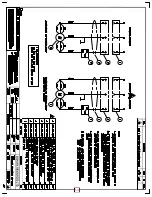

CONNECT INCOMING AIR SUPPLY TO POPPET

VALVE BESIDE POWER UNIT.

SEE PNUEMATIC

TUBING & FITTING LIST (PG 2-4).

CONNECT HYDRAULIC LINE AND AIR LINE FROM

POWER UNIT TO CONNECTIONS AT LIFT. ENSURE

THAT ALL FITTINGS ARE TIGHTENED.

SEE

HYDRAULIC AND PNUEMATIC TUBING &

FITTING LISTS (PG 2-3 & 2-4).

CONNECT THE PIVOT PADS TO THE PLATFORMS

USING THE PIVOT PAD PINS AND WASHERS. NOTE

SPECIFIC PLACEMENT OF WASHERS.

(REFER TO PG 3-2)

CONNECT INCOMING POWER TO POWER UNIT.

SEE

ELECTRICAL SCHEMATIC (PG 2-5)

BLEEDING HYDRAULIC SYSTEM:

RAISE UNIT FULLY. FOR NEXT STEP, HAVE CLOTH

AVAILABLE TO WIPE UP DRIPPING HYDRAULIC

FLUID.

- CAUTION -

THE FOLLOWING PROCEDURE CAN BE

INHERENTLY DANGEROUS IF NOT PERFORMED TO

THE FOLLOWING PROCEDURE.

ALWAYS USE

CAUTION WHEN BLEEDING UNIT

, AND NEVER

REMOVE PLUGS FULLY. BE AWARE AND STAY

CLEAR OF ANY PROJECTING FLUID.

SLOWLY AND CAREFULLY LOOSEN

(DO NOT REMOVE)

PLUGS ON ENDS OF BOTH

BARRELS OF CYLINDERS UNTIL AIR BUBBLES

FORM (APPROXIMATELY A QUARTER TO HALF A

FULL TURN). WAIT FOR CYLINDERS TO FINISH

VENTING TRAPPED AIR. TIGHTEN PLUGS. FULLY

LOWER UNIT.

RAISE UNIT FULLY AND OBSERVE SMOOTH

LIFTING. IF LIFT IS VIBRATING WHILE LIFTING,

REPEAT PROCEDURE FOR BLEEDING HYDRAULIC

SYSTEM.

FULLY CYCLE THE UNIT THREE TIMES TO

FAMILIARIZE YOURSELF WITH THE FUNCTIONS OF

THE UNIT, AND TO ALLOW ALL AIR TO BE

REMOVED FROM THE HYDRAULIC SYSTEM.

ENSURE PROPER LOCK ENGAGEMENT & TEST

LOCK DISENGAGEMENT BY PRESSING THE LOCK

RELEASE BUTTON ON THE POWER UNIT DOLLY

ASSEMBLY.

Содержание USL-6000-K

Страница 2: ......

Страница 17: ...MOHAWK MODEL USL 6000 K 1 10 MAINTENANCE CHART DATE MAINTENANCE PERFORMED SERVICE COMPANY SERVICED BY ...

Страница 18: ...MOHAWK MODEL USL 6000 K MOHAWK FIGURES DIAGRAMS MOHAWK RESOURCES LTD MODEL USL 6000 K ...

Страница 19: ......

Страница 20: ......

Страница 21: ...2 3 ...

Страница 22: ...2 4 2 4 ...

Страница 23: ...2 5 ...

Страница 24: ...2 6 ...

Страница 25: ...2 6 ...

Страница 26: ...MOHAWK MODEL USL 6000 K MOHAWK PARTS MOHAWK RESOURCES LTD MODEL USL 6000 K ...

Страница 27: ...PAGE 1 OF 7 ...

Страница 28: ...PAGE 2 OF 7 ...

Страница 29: ...PAGE 3 OF 7 ...

Страница 30: ...PAGE 4 OF 7 ...

Страница 31: ...PAGE 5 OF 7 ...

Страница 34: ...MOHAWK MODEL USL 6000 K MOHAWK TOW BAR KIT MOHAWK RESOURCES LTD MODEL USL 6000 K ...

Страница 36: ......

Страница 37: ......

Страница 38: ......