6

1. Installing the Keel & Stem

Like the bulwarks, the model keel is modi-

fied from the real boat as can be seen on the

plans. The model keel is 1/16" deep x 3/32"

wide basswood. Fit it from Station 10 for-

ward up to the heavier pipe stem piece

which starts just below the waterline. For the

curved portion of the keel, steam bend the

strip or cut it out of a wider sheet of 3/32"

thick wood.

On the real boat the heavy stem is a round

pipe. It is actually fitted over the keel bar

which goes up to the deck. If you have not

done so yet, cut or sand in the notch for the

stem, 1/32" deep. For the heavy stem, add

either a 1/8" diameter dowel. Or a 1/8"

square basswood strip. For the square, sand

the forward side round and sand the back

edges down to the hull. Use wood filler as

necessary to smooth out the joint between

the stem and hull (Figure B-1).

2. Installing the Sternpost, Prop

Shaft Tube Fairing, & Propeller

The sternpost is a 3/32" thick laser-cut wood

part. This is actually part of large forging at

the stern of the real boat that includes the

stern tube. Glue this part to the hull. If it is

not the same width as the hull you have

carved from Stage A, sand the hull flush with

the laser-cut part, or if necessary add wood

filler on the hull so the two will fair. Next,

add the shaft tube fairings on both sides. Cut

these from basswood. Shape the inboard

sides to the hull shape. The outer faces

should be parallel to the hull’s centerline. On

the real boat this is just a hump in the hull

plating that covers the stern tube which

would protrude thru the hull if not covered.

Install the propeller. The prop has a shaft

piece that should fit in the slot in the laser-

cut sternpost . You may need to shorten the

shaft on the prop, or drill a hole at the slot

deeper into the hull (Figure B-2).

3. Installing the Rudder Skeg

& Rudder

As noted in Paragraph 1 above, the keel was

installed forward of station 10. Aft of Station

10 you will add the 3/32" thick laser-cut rud-

der support skeg which extends beyond the

hull. If you have not yet carved the notch for

the skeg, do so now. The bottom of the skeg

should be in line with the bottom of the keel.

Drill a hole in the hull for the upper end of

the rudder stock. At the end of the laser-cut

skeg (part 1), add the laser-cut block (part 2)

which has a hole for the lower end of the

rudder stock. Round the outer edges of the

skeg per the plan.

The rudder is a Britannia casting with the

stock already molded in. Fit the upper end

in the hole in the hull, then in the skeg, and

finally glue the skeg to the hull. You will

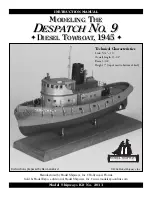

STAGE B:

COMPLETING THE BASIC HULL STRUCTURES

FIG. B-1 KEEL & STEM

FIG. B-2 STERNPOST, FAIRING

& PROP

FIG. B-3 RUDDER SKEG

& RUDDER

FIG. B-4 BULWARK DETAILS

ROUND EDGES

NOTCH

FOR STEM

CUT & ADD

WOOD FILLER

FOR CURVED

BOTTOM END

3/32" x 1/6" KEEL

BACK TO STA. 10

LASER-CUT

PART

KEEL

FAIRING

SHAPE

TO HULL

RUDDER CASTING,

CUT-OFF SHAFT

TO FIT HOLE

LASER-CUT

SKEG

PART 2

ROUND

EDGE

LASER-CUT

SKEG

PART 1

PROP CASTING

NOTCH FOR SKEG

QUARTER BITT

CASTING

CAP RAIL

TYPICAL

BRACKET

TYPICAL

STIFFENER

HAWSE PIPE

LIP CASTING

CHOCK CASTING

ADD WOOD FILLER

USING DOWEL

USING

1/8" SQUARE