2. Control Unit Installation

2.1 Mechanical

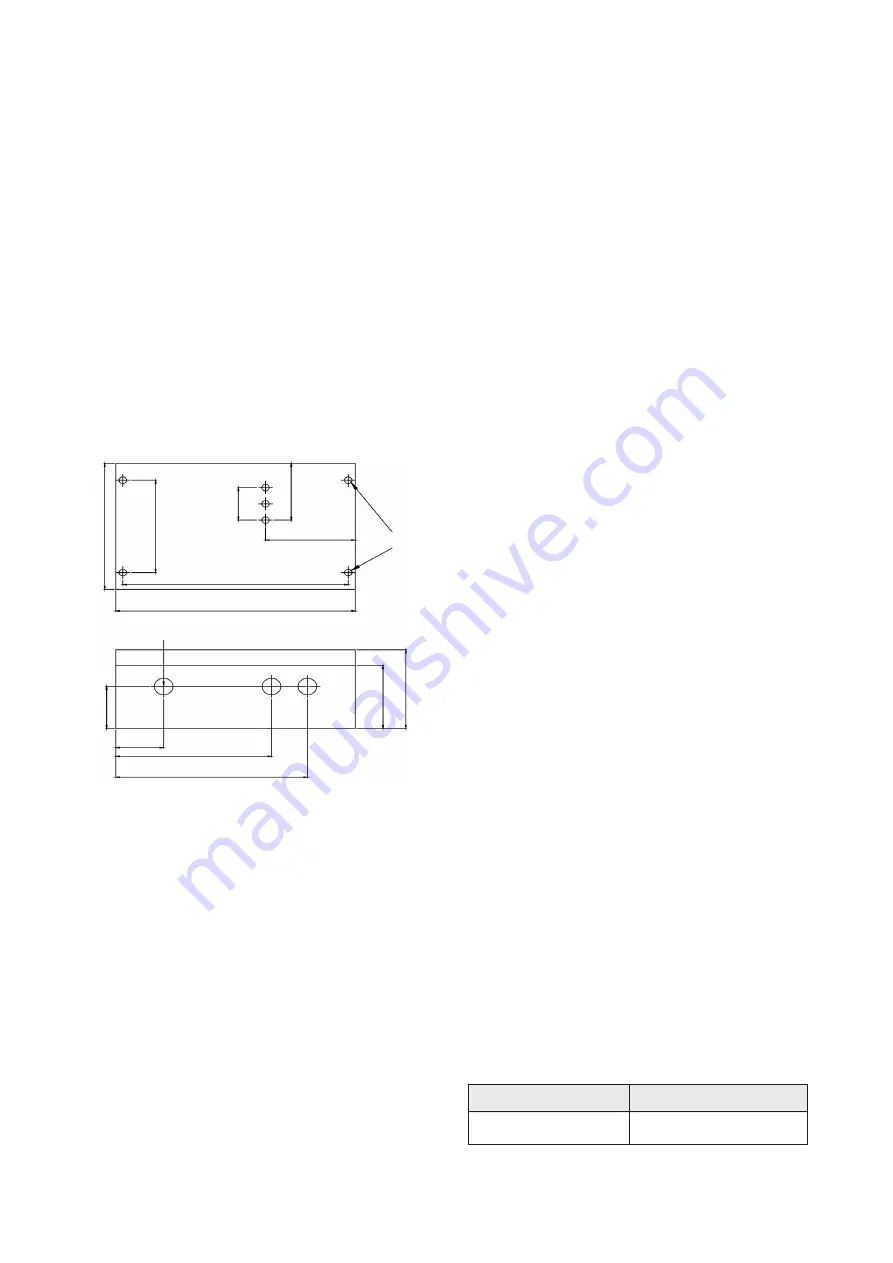

The control unit is supplied with three holes drilled in the

bottom (longer) side of the box. Two glands are supplied

for the power input cable and relay output cable. The

sensor is normally supplied fitted with a suitable gland

on the cable. Two further holes can be drilled in the

bottom side of the box should these be needed: it is

recommended that the circuit board is removed whilst

drilling extra gland holes.

Determine suitable mounting location with regards to :

a) Surface composition / load bearing capacity

b) Cable length restrictions

c) Accessibility for servicing

All cable connections are made to the terminal blocks

along the bottom edge of the pcb (see fig.5). Release

the terminal screw before inserting the wire.

Fig. 3 MCU200 housing dimensions

2.2 External Connections

Protection for permanently installed equipment

NOTE: This equipment is regarded as permanently

installed equipment and must be wired up using

suitable cable for the current and voltage specified. A

suitable switch or circuit breaker must be included in

the installation and this should be in close proximity

to the equipment and marked as its disconnecting

device. A suitable fuse rated at 3A must be fitted in

the supply. Each relay circuit must be protected by a

fuse not exceeding the maximum rated current for the

relay as specified in the manual. As S/C current on the

transformer secondary is in the order of 70 mA and the

transformer thermal fuse will not operate for at least 17

minutes (as tested) a smaller value mains fuse (63mA)

should be agreed upon.

Two cables are required per sensor. The RG178 should

be used where the cable itself is subject to temperatures

exceeding 74°C.

Page 5

120

88

188

200

31

54

75

mounting

holes

1.015

40

140

130

160

75

60

(i)

AC Mains

is connected between the “N” terminal

for neutral and one of the “115V” or “230V” terminals

depending on the voltage supply available - BEWARE -

the terminal not connected externally will be “live” once

the transformer is powered via the other terminals.

(ii)

Protective earth

NOTE: A protective earth should be used for all

applications

(iii)

The DPCO relay

has two sets of contacts. These

are labelled:

Set 1:

NC1

- Normally closed

C1

- Common

NO1

- Normally open

Set 2:

NC2

- Normally closed

C2

- Common

NO2

- Normally open

R

elay warning

CAUTION: If the relay is connected to external

hazardous live (mains) circuits then external circuits

(such as signal circuits) with accessible parts and/or

basic insulation only MUST NOT be connected to the

relay.

(iv)

The Sensor

connections are labelled “1”, “E” for

the receiver crystal and “2”, “E” for the coax cable to the

transmitter crystal. The screens of these coax cables

are connected to the terminals marked “E”.

(v)

The Auxiliary Input

is a terminal which can be

connected to a “push to reset” button to achieve a

latching alarm, or to another Mobrey control unit, to give

a pump control from the MCU200 unit relay output. If a

short circuit is connected between terminals 3 & 4, the

MCU200 relay, once de-energised, is held de-energised.

Even if the sensor attached to the MCU200 changes

state, to that which should energise the output relay, this

relay will not energise until the link between terminals 3

& 4 is broken in the circuit external to the MCU200. See

section 3.3.

2.3 Switch Settings in MCU200 Series

(i)

Gain switch

(and potentiometer): See section 3.

(ii)

Frequency selection

This slide switch is labelled “FREQ” and is located

between the sensor terminal block E2, and the Aux input

terminals. This selects the operating frequency of the

MCU200 oscillator, which is either 3.7MHz (switch in the

'up' position) or 1 MHz, (switch to the down position).

The ex-factory setting is to 1 MHz. The setting required

is dictated by the sensor type connected to the control

unit. Usually these are:

Fig. 4 Sensor frequencies

1MHz sensors

30*S, 33*S

3.7 MHz sensors

40*S, 43*S, 44*S