5

55

5Maintenance and Inspection

Maintenance and Inspection

Maintenance and Inspection

Maintenance and Inspection

Resetting the origin

Resetting the origin

Resetting the origin

Resetting the origin

5

55

5-

--

-55

55

55

55

5.5 Resetting the origin

5.5 Resetting the origin

5.5 Resetting the origin

5.5 Resetting the origin

The origin is set so that the robot can be used with a high accuracy. After purchasing the robot, always carry out

The origin is set so that the robot can be used with a high accuracy. After purchasing the robot, always carry out

The origin is set so that the robot can be used with a high accuracy. After purchasing the robot, always carry out

The origin is set so that the robot can be used with a high accuracy. After purchasing the robot, always carry out

this step before starting work. The origin must be reset if the combination of robot and controller being used is

this step before starting work. The origin must be reset if the combination of robot and controller being used is

this step before starting work. The origin must be reset if the combination of robot and controller being used is

this step before starting work. The origin must be reset if the combination of robot and controller being used is

changed or if the motor is changed causing an encoder area.

changed or if the motor is changed causing an encoder area.

changed or if the motor is changed causing an encoder area.

changed or if the motor is changed causing an encoder area.

The types of origin setting methods are shown in Table 5-6.

The types of origin setting methods are shown in Table 5-6.

The types of origin setting methods are shown in Table 5-6.

The types of origin setting methods are shown in Table 5-6.

Table 5-6

:

Origin setting method

Table 5-6

:

Origin setting method

Table 5-6

:

Origin setting method

Table 5-6

:

Origin setting method

5.5.

1

Jig method

5.5.

1

Jig method

5.5.

1

Jig method

5.5.

1

Jig method

The method for setting the origin with the transportation jig is explained below.

The method for setting the origin with the transportation jig is explained below.

The method for setting the origin with the transportation jig is explained below.

The method for setting the origin with the transportation jig is explained below.

This operation is carried out with the T/B. Set the [MODE] switch on the front of the controller to "TEACH", and

This operation is carried out with the T/B. Set the [MODE] switch on the front of the controller to "TEACH", and

This operation is carried out with the T/B. Set the [MODE] switch on the front of the controller to "TEACH", and

This operation is carried out with the T/B. Set the [MODE] switch on the front of the controller to "TEACH", and

set the T/B [ENABLE/DISABLE] switch to "ENABLE" to validate the T/B. Move the J4 axis to the upper end

set the T/B [ENABLE/DISABLE] switch to "ENABLE" to validate the T/B. Move the J4 axis to the upper end

set the T/B [ENABLE/DISABLE] switch to "ENABLE" to validate the T/B. Move the J4 axis to the upper end

set the T/B [ENABLE/DISABLE] switch to "ENABLE" to validate the T/B. Move the J4 axis to the upper end

with jog operation beforehand.

with jog operation beforehand.

with jog operation beforehand.

with jog operation beforehand.

The following operation is carried out while lightly pressing the T/B deadman switch.

The following operation is carried out while lightly pressing the T/B deadman switch.

The following operation is carried out while lightly pressing the T/B deadman switch.

The following operation is carried out while lightly pressing the T/B deadman switch.

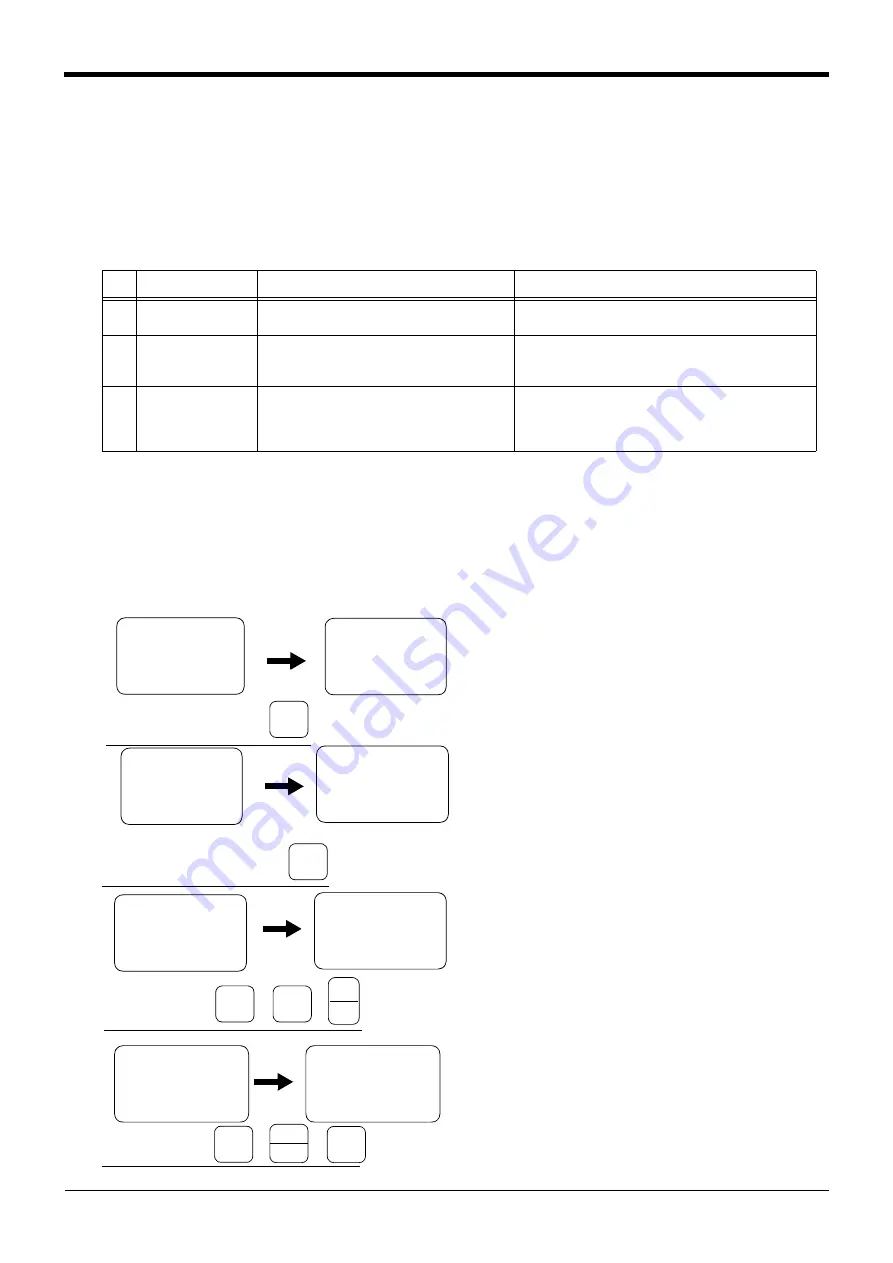

1

) Press the [5] key on the menu screen, and

1

) Press the [5] key on the menu screen, and

1

) Press the [5] key on the menu screen, and

1

) Press the [5] key on the menu screen, and

display the maintenance screen.

display the maintenance screen.

display the maintenance screen.

display the maintenance screen.

2) Press the [4] key on the maintenance screen,

2) Press the [4] key on the maintenance screen,

2) Press the [4] key on the maintenance screen,

2) Press the [4] key on the maintenance screen,

and display the origin setting method selection

and display the origin setting method selection

and display the origin setting method selection

and display the origin setting method selection

screen.

screen.

screen.

screen.

3) Press the [3] key and select the jig method.

3) Press the [3] key and select the jig method.

3) Press the [3] key and select the jig method.

3) Press the [3] key and select the jig method.

Then, press the [

1

] key and the [INP] key to

Then, press the [

1

] key and the [INP] key to

Then, press the [

1

] key and the [INP] key to

Then, press the [

1

] key and the [INP] key to

turn the servo OFF.

turn the servo OFF.

turn the servo OFF.

turn the servo OFF.

Securely fix the transportation jig A to the base

Securely fix the transportation jig A to the base

Securely fix the transportation jig A to the base

Securely fix the transportation jig A to the base

with the fixing bolts (M4

with the fixing bolts (M4

with the fixing bolts (M4

with the fixing bolts (M4 x

x

x

x

1

2, 2 bolts) in this

1

2, 2 bolts) in this

1

2, 2 bolts) in this

1

2, 2 bolts) in this

state.

state.

state.

state.

4) As for a release of the brake, set "

1

" to the axis

4) As for a release of the brake, set "

1

" to the axis

4) As for a release of the brake, set "

1

" to the axis

4) As for a release of the brake, set "

1

" to the axis

column of the "BRAKE" which the brakes are to

column of the "BRAKE" which the brakes are to

column of the "BRAKE" which the brakes are to

column of the "BRAKE" which the brakes are to

be released, and press the [+X] key while holding

be released, and press the [+X] key while holding

be released, and press the [+X] key while holding

be released, and press the [+X] key while holding

down the [MOVE] key. The brake of specified

down the [MOVE] key. The brake of specified

down the [MOVE] key. The brake of specified

down the [MOVE] key. The brake of specified

axis will be released only while the [+X] key is

axis will be released only while the [+X] key is

axis will be released only while the [+X] key is

axis will be released only while the [+X] key is

pressed.

pressed.

pressed.

pressed.

No

No

No

No

Method

Method

Method

Method

Explanation

Explanation

Explanation

Explanation

Remarks

Remarks

Remarks

Remarks

1

11

1

Origin data input

Origin data input

Origin data input

Origin data input

method

method

method

method

The origin data set as the default is input from

The origin data set as the default is input from

The origin data set as the default is input from

The origin data set as the default is input from

the T/B.

the T/B.

the T/B.

the T/B.

The setting method is explained in "2.3 Setting the origin" on

The setting method is explained in "2.3 Setting the origin" on

The setting method is explained in "2.3 Setting the origin" on

The setting method is explained in "2.3 Setting the origin" on

page

2

22

2

Jig method

Jig method

Jig method

Jig method

The transportation jig is installed, and the

The transportation jig is installed, and the

The transportation jig is installed, and the

The transportation jig is installed, and the

transportation posture is set as the origin

transportation posture is set as the origin

transportation posture is set as the origin

transportation posture is set as the origin

posture.

posture.

posture.

posture.

The setting method is explained in "5.5.

The setting method is explained in "5.5.

The setting method is explained in "5.5.

The setting method is explained in "5.5.

55.

55.

55.

55.

3

33

3

User origin method

User origin method

User origin method

User origin method

A randomly designated position is set as the

A randomly designated position is set as the

A randomly designated position is set as the

A randomly designated position is set as the

origin posture.

origin posture.

origin posture.

origin posture.

Before using this method, the origin must be set with the origin

Before using this method, the origin must be set with the origin

Before using this method, the origin must be set with the origin

Before using this method, the origin must be set with the origin

data input method (No.

1

above) or jig method (No. 2 above).

data input method (No.

1

above) or jig method (No. 2 above).

data input method (No.

1

above) or jig method (No. 2 above).

data input method (No.

1

above) or jig method (No. 2 above).

The setting method is explained in "5.5.2 User origin method" on

The setting method is explained in "5.5.2 User origin method" on

The setting method is explained in "5.5.2 User origin method" on

The setting method is explained in "5.5.2 User origin method" on

page 58.

<MENU>

<MENU>

<MENU>

<MENU>

1

.TEACH 2.RUN

1

.TEACH 2.RUN

1

.TEACH 2.RUN

1

.TEACH 2.RUN

3.FILE 4.MONI

3.FILE 4.MONI

3.FILE 4.MONI

3.FILE 4.MONI

5.MAINT 6.SET

5.MAINT 6.SET

5.MAINT 6.SET

5.MAINT 6.SET

<MAINT>

<MAINT>

<MAINT>

<MAINT>

1

.

1

.

1

.

1

.PARAM 2.INIT

PARAM 2.INIT

PARAM 2.INIT

PARAM 2.INIT

3.BRAKE 4.

3.BRAKE 4.

3.BRAKE 4.

3.BRAKE 4.ORIGIN

ORIGIN

ORIGIN

ORIGIN

5.POWER

5.POWER

5.POWER

5.POWER

Display the maintenance screen

Display the maintenance screen

Display the maintenance screen

Display the maintenance screen

+C

+C

+C

+C

(J6)

(J6)

(J6)

(J6)

5

5

5

5

STU

STU

STU

STU

<JIG>

<JIG>

<JIG>

<JIG>

SERVO OFF

SERVO OFF

SERVO OFF

SERVO OFF

OK ? (

1

)

OK ? (

1

)

OK ? (

1

)

OK ? (

1

)

1

:EXECUTE

1

:EXECUTE

1

:EXECUTE

1

:EXECUTE

Display the method selection screen

Display the method selection screen

Display the method selection screen

Display the method selection screen

<MAINT>

<MAINT>

<MAINT>

<MAINT>

1

.

1

.

1

.

1

.PARAM 2.INIT

PARAM 2.INIT

PARAM 2.INIT

PARAM 2.INIT

3.BRAKE 4.

3.BRAKE 4.

3.BRAKE 4.

3.BRAKE 4.ORIGIN

ORIGIN

ORIGIN

ORIGIN

5.POWER

5.POWER

5.POWER

5.POWER

<ORIGIN>

<ORIGIN>

<ORIGIN>

<ORIGIN>

1

.DATA 2.MECH

1

.DATA 2.MECH

1

.DATA 2.MECH

1

.DATA 2.MECH

3.JIG 4.ABS

3.JIG 4.ABS

3.JIG 4.ABS

3.JIG 4.ABS

5.USER

5.USER

5.USER

5.USER

-Y

-Y

-Y

-Y

(J2)

(J2)

(J2)

(J2)

4

44

4

MNO

MNO

MNO

MNO

<ORIGIN>

<ORIGIN>

<ORIGIN>

<ORIGIN>

1

.DATA 2.MECH

1

.DATA 2.MECH

1

.DATA 2.MECH

1

.DATA 2.MECH

3.JIG 4.ABS

3.JIG 4.ABS

3.JIG 4.ABS

3.JIG 4.ABS

5.USER

5.USER

5.USER

5.USER

Select the jig method

Select the jig method

Select the jig method

Select the jig method

-Z

-Z

-Z

-Z

(J3)

(J3)

(J3)

(J3)

3

33

3

JKL

JKL

JKL

JKL

→

→

→

→

-B

-B

-B

-B

(J5)

(J5)

(J5)

(J5)

1

11

1

DEF

DEF

DEF

DEF

→

→

→

→

INP

INP

INP

INP

EXE

EXE

EXE

EXE

Release the brakes

Release the brakes

Release the brakes

Release the brakes

<AXIS>

1

2345678

<AXIS>

1

2345678

<AXIS>

1

2345678

<AXIS>

1

2345678

BRAKE

BRAKE

BRAKE

BRAKE (00000000)

(00000000)

(00000000)

(00000000)

SET AXIS

SET AXIS

SET AXIS

SET AXIS (00000000)

(00000000)

(00000000)

(00000000)

ORIGIN :NOT DEF

ORIGIN :NOT DEF

ORIGIN :NOT DEF

ORIGIN :NOT DEF

STEP

STEP

STEP

STEP

MOVE

MOVE

MOVE

MOVE

+X

+X

+X

+X

(J

1

)

(J

1

)

(J

1

)

(J

1

)

.

.

.

.

ユ

;^

ユ

;^

ユ

;^

ユ

;^

+

+

+

+

-B

-B

-B

-B

(J5)

(J5)

(J5)

(J5)

1

11

1

DEF

DEF

DEF

DEF

→

→

→

→

<AXIS>

1

2345678

<AXIS>

1

2345678

<AXIS>

1

2345678

<AXIS>

1

2345678

BRAKE

BRAKE

BRAKE

BRAKE ((((

1111

1111

1111

1111

0000)

0000)

0000)

0000)

SET AXIS

SET AXIS

SET AXIS

SET AXIS (00000000)

(00000000)

(00000000)

(00000000)

ORIGIN :NOT DEF

ORIGIN :NOT DEF

ORIGIN :NOT DEF

ORIGIN :NOT DEF