ENGINE COOLING -

On-vehicle Service

14-9

14100100136

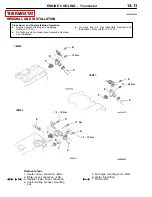

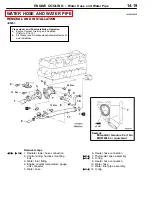

ENGINE COOLANT LEAK CHECKING

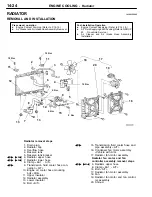

1. Confirm that the coolant level is up to the filler neck.

Install a radiator cap tester and apply 160 kPa pressure,

and then check for leakage from the radiator hose or

connections.

Caution

(1) Be sure to completely clean away any moisture

from the places checked.

(2) When the tester is taken out, be careful not to

spill any coolant from it.

(3) Be careful, when installing and removing the tester

and when testing, not to deform the filler neck

of the radiator.

2. If there is leakage, repair or replace the appropriate part.

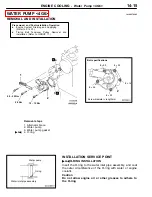

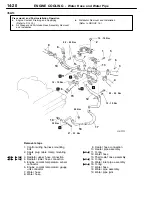

RADIATOR CAP OPENING PRESSURE CHECK

14100130159

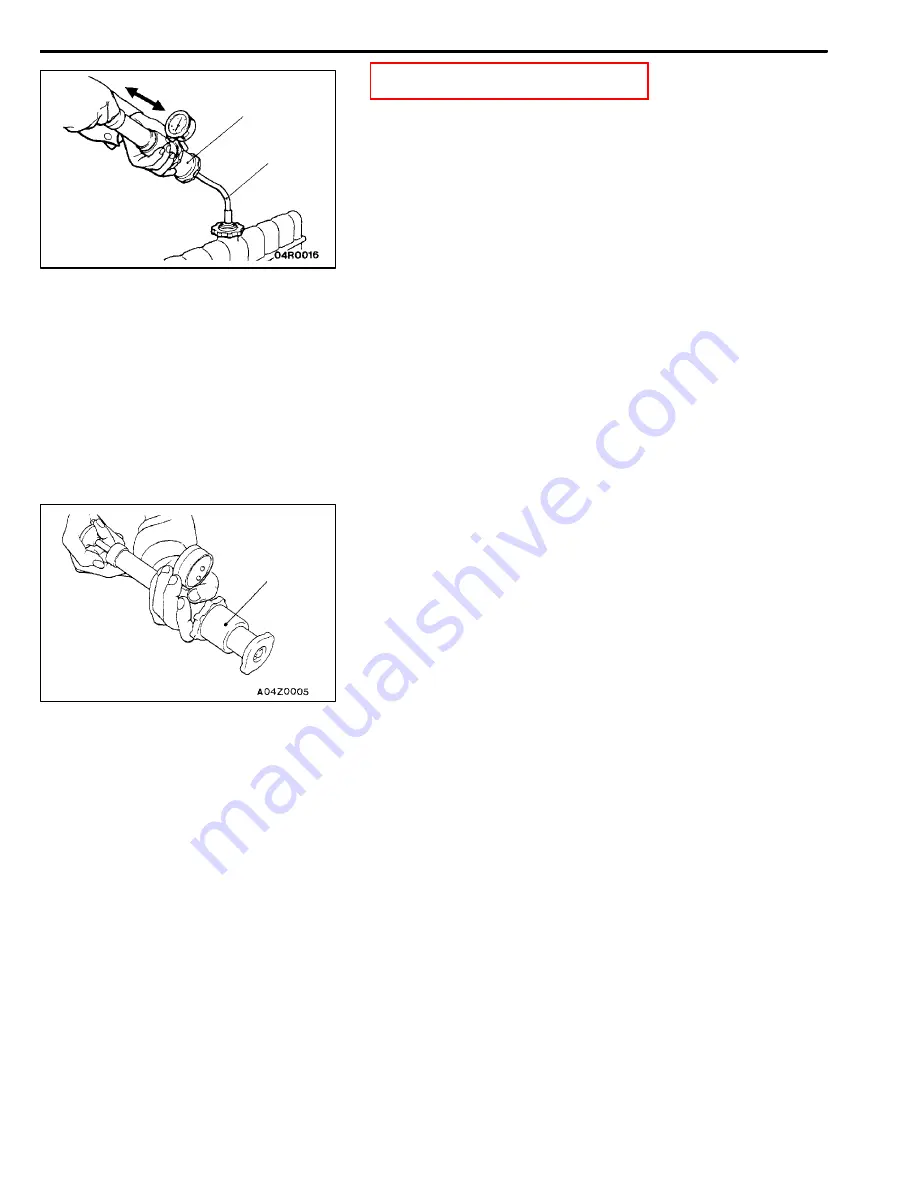

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge

stops moving.

Limit: 64 kPa

Standard value: 74 - 103 kPa

3. Replace the radiator cap if the reading does not remain

at or above the limit.

NOTE

Be sure that the cap is clean before testing, since rust

or other foreign material on the cap seal will cause an

improper indication.

Cap adapter

Adapter

Cap adapter

Содержание Engine cooling

Страница 26: ...NOTES ...