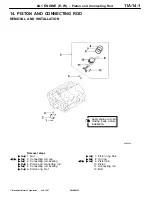

6A1 ENGINE (E - W) -

Piston and Connecting Rod

11A-14-3

INSTALLATION SERVICE POINTS

"

A

A

PISTON PIN INSTALLATION

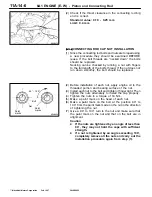

(1) Measure the following dimensions of the piston, piston

pin and connecting rod.

A: Piston pin insertion hole length

B: Distance between piston bosses

C: Piston pin length

D: Connecting rod small end width

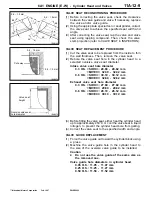

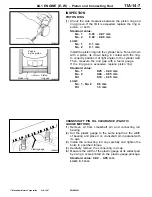

(2) Calculate the following formula by substituting the

measured values.

(A - C) - (B - D)

2

L =

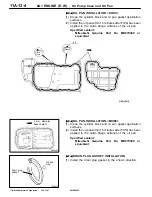

(3) Insert the Push Rod (special tool) into the piston pin and

attach the guide A to the push rod end.

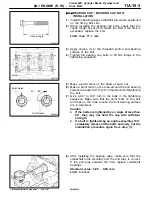

(4) Assemble the connecting rod in the piston with their front

marks facing the same direction.

(5) Apply engine oil to the entire periphery of the piston pin.

(6) Insert the piston pin, push rod and guide A assembly

having assembled in step (3) from the guide A side into

the piston pin hole on the front marked side.

(7) Screw the guide B into the guide A until the gap between

both guides amounts to the value L obtained in step

(2) plus 3 mm.

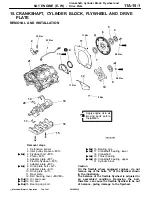

(8) Place the piston and connecting rod assembly onto the

piston setting base with the front marks directed upward.

(9) Press-fit the piston pin using a press.

If the press-fitting force required is less than the standard

value, replace the piston and piston pin set or/and the

connecting rod.

Standard value: 5,000 - 15,000 N

PWEE9622

E

Feb. 1997

Mitsubishi Motors Corporation

7EN0432

Piston

Piston pin

Connecting rod

A

B

C

D

7EN0433

3 mm + L

Guide B

Guide A

7EN0391

Push rod

Piston pin

Front mark

Front

mark

Guide A

Base

Guide B