–30–

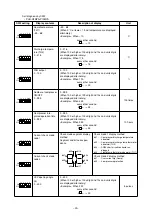

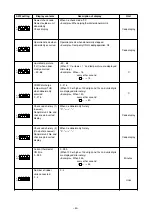

Newest check code

Newest outdoor unit

abnormality

Check display

Operation mode when

abnormality occurred

Liquid temperature

(TH1) when abnor-

mality occurred

– 39 - 88

COMP discharge

temperature (TH2)

when abnormality

occurred

0 - 216

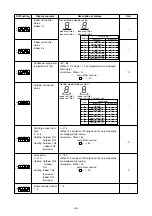

Check code history (1)

(newest)

Abnormal unit No. and

check code inverted

display

Check code history (2)

(One before newest)

Abnormal unit No. and

check code inverted

display

Current thermostat

ON time

0 - 999

Number of indoor

units connected

0 - 4

When no check mode,“00”

<Example> When piping thermistor abnormal U4

Operation mode when abnormally stopped

<Example> Comp. only ON at cooling operation C4

–39 - 88

(When 0

°

C or lower, “–” and temperature are displayed

alternately.)

<Example> When –15,

every other second

–

←→

15

0 - 216

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 130,

every other second

1

←→

30

When no abnormality history

“0”, “

←→

”, “–”

When no abnormality history

“0”, “

←→

”, “–”

0 - 999

(When 100 or higher, 100s digit and 10s and units digits

are displayed alternately.)

<Example> When 245,

every other second

2

←→

45

0 - 4

Code display

Code display

°

C

°

C

Code display

Code display

Minutes

Units

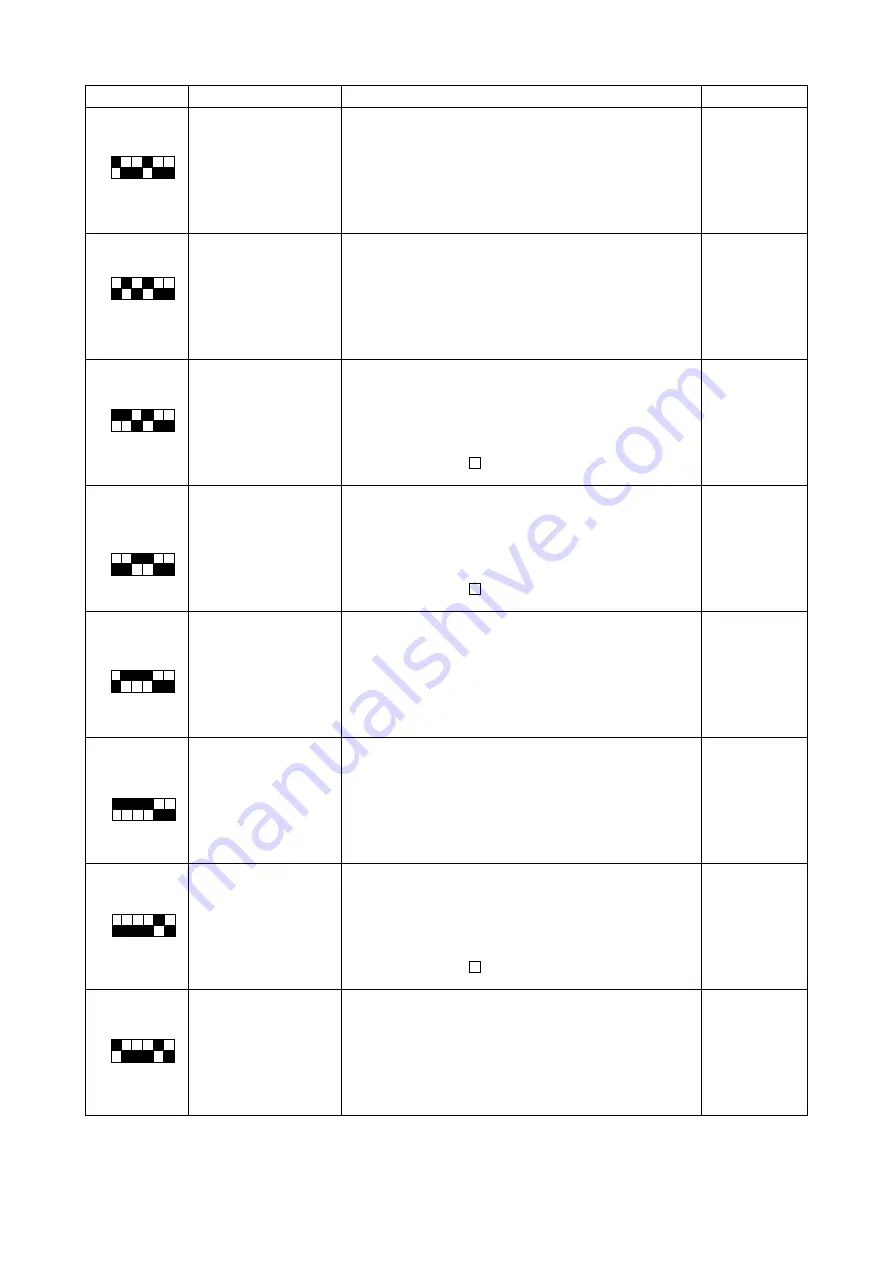

SW2 setting

Display contents

Description of display

Unit

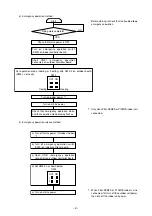

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF

1 2 3 4 5 6

ON

OFF