6 - 3

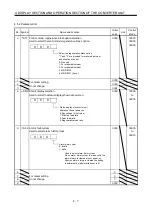

6. TROUBLESHOOTING

Indication

Name

Definition

Cause

Action

1. Power supply voltage is low.

2. Instantaneous control power failure

occurred for more than 100ms.

3. Shortage of power supply capacity

caused the power supply voltage to

drop at start, etc.

4. Power switched on within 5s after it

had switched off.

Review the power supply.

A.10

Undervoltage

Control power supply

voltage dropped to

160V or less.

5. Faulty parts in the servo amplifier

Checking method

Alarm (A.10) occurs if power is

switched on after all connectors

are disconnected.

Change the Converter unit.

A.12

Memory alarm 1 RAM, ROM memory

fault

A.13

Clock alarm

Printed board fault

A.15

Memory alarm 2 EEP-ROM fault

Failure of the part in the converter unit.

Alarm (A.10, A.13, A.15) occurs

if all connectors are disconnected

and power is switched on.

Checking method

Change the Converter unit.

1. Wrong setting of parameter No. 0

Set correctly.

2. Regenerative brake option is not

connected.

Connect correctly.

3. High-duty operation or continuous

regenerative operation caused the

permissible regenerative power of

the regenerative brake option to be

exceeded.

Checking method

Call the status display and check

the regenerative load ratio.

1. Reduce the frequency of

positioning.

2. Use the regenerative brake

option of larger capacity.

3. Reduce the load.

4. Power supply voltage is

abnormal.260V or more

Review power supply

5. Regenerative transistor faulty.

Checking method

1) The regenerative brake option

has overheated abnormally.

2) The alarm occurs even after

removal of the built-in

regenerative brake resistor or

regenerative brake option.

Change the Converter unit.

6. Regenerative brake option faulty.

Change Converter unit or

regenerative brake option.

A.30

Regenerative

alarm

Permissible

regenerative power of

the built-in

regenerative brake

resistor or

regenerative brake

option is exceeded.

7. Unusual overheat due to cooling fan

stop

1. Change the Converter unit or

cooling fan.

2. Reduce ambient temperature.

1. Lead of regenerative brake option is

open or disconnected.

1. Change lead.

2. Connect correctly.

2. Regenerative transistor faulty.

3. Wire breakage of regenerative

brake option

1. For wire breakage of built-in

regenerative brake resistor,

change servo amplifier.

2. For wire breakage of regenerative

brake option, change regenerative

brake option.

A.33

Over voltage

Converter bus voltage

exceeded 400V.

4. Capacity of regenerative brake

option is insufficient.

Add regenerative brake option or

increase capacity.

1. Servo amplifier fault caused the

parameter setting to be rewritten.

Change the Converter unit.

A.37

Parameter

alarm

Parameter setting is

wrong.

2. Parameter data mis-setting.

Set parameter correctly.

1. Servo amplifier faulty.

Change the servo amplifier

2. The power supply was turned on and

off continuously by overloaded status.

The drive method is reviewed.

A.45

Main circuit

device overheat

Main circuit device

overheat

3. Air cooling fan of servo amplifier stops. The cooling method is reviewed.

A.50

Over load 1

Load exceeded

overload protection

characteristic of

Converter unit

Converter unit is used in excess of its

continuous output current.

1. Reduce load.

2. Review operation pattern.

Содержание Melservo-H Series

Страница 11: ... 4 MEMO ...

Страница 23: ...1 12 1 FUNCTIONS AND CONFIGURATION MEMO ...

Страница 41: ...3 16 3 SIGNALS AND WIRING MEMO ...

Страница 49: ...4 8 4 DISPLAY SECTION AND OPERATION SECTION OF THE CONVERTER UNIT MEMO ...

Страница 61: ...7 6 7 OUTLINE DIMENSIONAL DRAWINGS MEMO ...

Страница 81: ...9 16 9 OPTIONS AND AUXILIARY EQUIPMENT MEMO ...

Страница 91: ...App 10 APPENDIX MEMO ...